Construction Site Video | Construction of In-situ Cold Recycling Test Section of High-early Strength and High-toughness Emulsified Asphalt in Shenzhen-Shantou Cooperation Zone

April 11, 2024

Recently,Provincial Highway in Shenzhen-Shantou Special Cooperation Zone S387(Goose port-Ping Shan)Mingxi Village Road Section,Led by Shenzhen-Shantou Administration Bureau of Shenzhen Transportation Bureau,Organize Shenzhen-Shantou Road Maintenance Management Office of Shenzhen Yuetong Construction Engineering Co., Ltd. to adopt new materials、New equipment、The new technology has implemented green maintenance to the road.。After regeneration and maintenance, the road surface has taken on a new look.,Created a set of green、Low carbon、Efficient、A New Mode of Pavement Maintenance with High Performance and Sustainable Development!

Click on the documentary video to learn about the construction

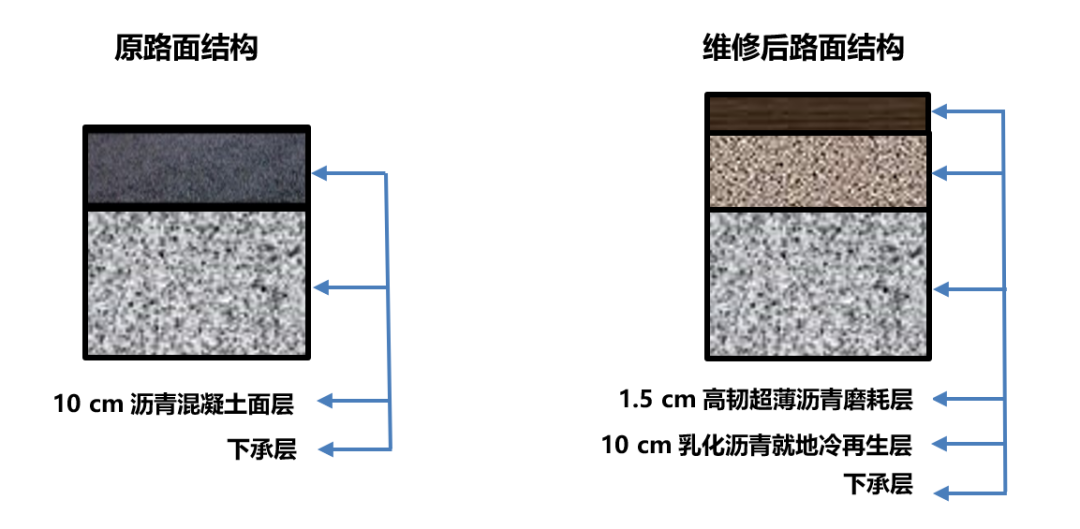

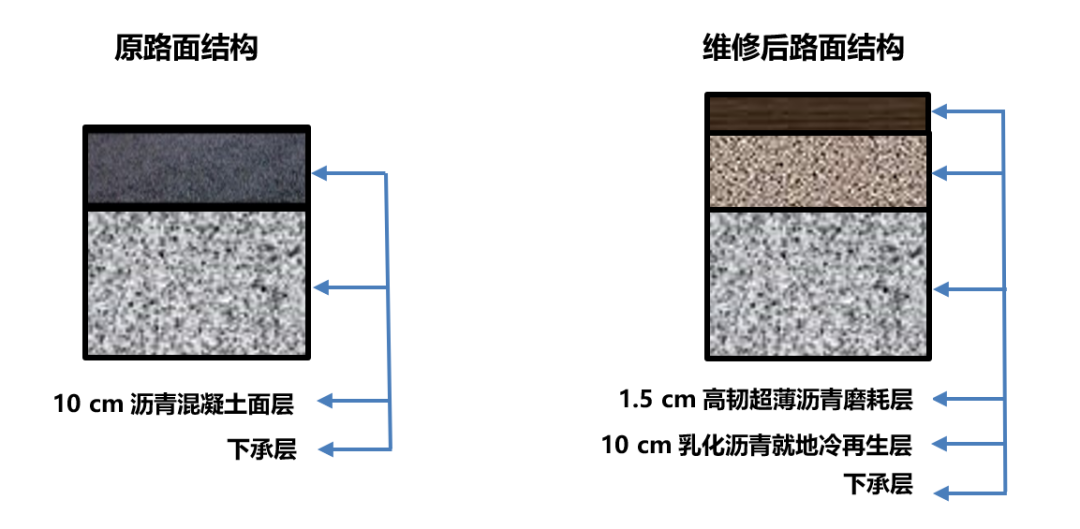

Technical proposal

The project uses a new set of Wittgen W 380 CR Super 1800 for Cold In-Place Regeneration Units and Fogler Equipped Spray Modules-3 Spray Jet Act as the main force of construction,The cold in-place recycling process of emulsified asphalt based on synchronous paving and the thin layer paving process based on synchronous spraying are used for road maintenance and reconstruction.。

Start with a set of Wirtgen based synchronous paving W 380 CR Cold in-place regeneration unit for the original 10 cm Asphalt concrete topping add approx. 5.6% High performance polymer modified emulsified asphalt for cold in-place recycling,The cold recycled material is repaved by the Vogler Paver.,And compact to form.,Temporary opening of traffic after spreading of tack coat。

After 2 days of curing, the cold recycling layer of emulsified asphalt,Using the Vogler Super 1800-3 Spray Jet Spray tack coat oil and pave 1 on cold regeneration layer synchronously.5 cm Thick, high-toughness and ultra-thin wear layer,Finish the overlay,Improve the surface function of the pavement,Effectively improve the driving comfort and safety of the road after maintenance。

During the whole maintenance process,Super 1800 equipped with spray module-3 Spray Jet It is used as a conventional Paver to pave the cold recycled material of emulsified asphalt.,And in the subsequent process.,As a dedicated model for special applications,Process for finishing wearing layer overlay by synchronously spraying adhesive layer oil,Implify construction process with one machine for two purpose,Further save construction cost。

Technical advantages

1.Low carbon and environmental protection

Old Pavement Material 100% Recycle and reuse,Save stone and asphalt,Reduce carbon emissions 65%。

2.Quick fix

High-efficiency cold in-place recycling technology based on synchronous paving technology、Fast,Traffic can be opened temporarily;After 2 days of conditioning,The construction of the synchronous high-toughness ultrathin wearing layer can be carried out on the cold recycling structural layer on the second day.,Thereby completing the entire pavement repair and quickly restoring traffic.。

3.Pavement structure optimization

High performance polymer modified emulsified asphalt cold recycling layer can effectively resist reflective cracking,At the same time, the high-toughness ultra-thin wearing layer can improve the surface function of the pavement.。