Lifecycle 3D Digital Twin Visualization Solution Enabling Smart Factory Construction

March 28, 2024

Intelligent factory is based on digital factory.,Strengthen information management and service by using the technology of Internet of Things and equipment monitoring technology,Master the production and marketing process、Improve the controllability of the production process、Reduce manual intervention on the production line、Collect production line data timely and correctly,As well as reasonable production planning.。

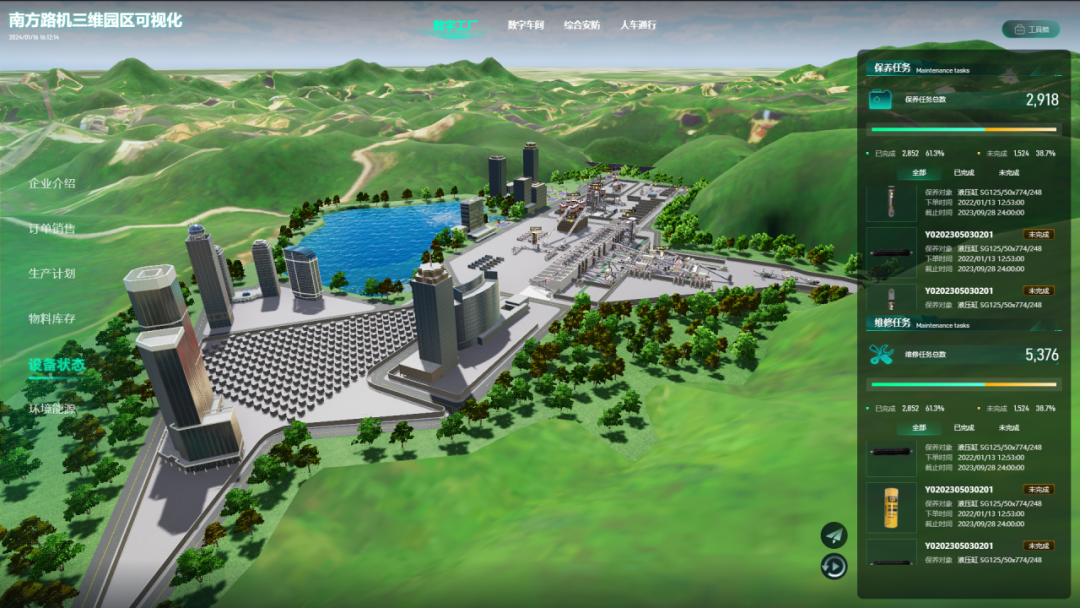

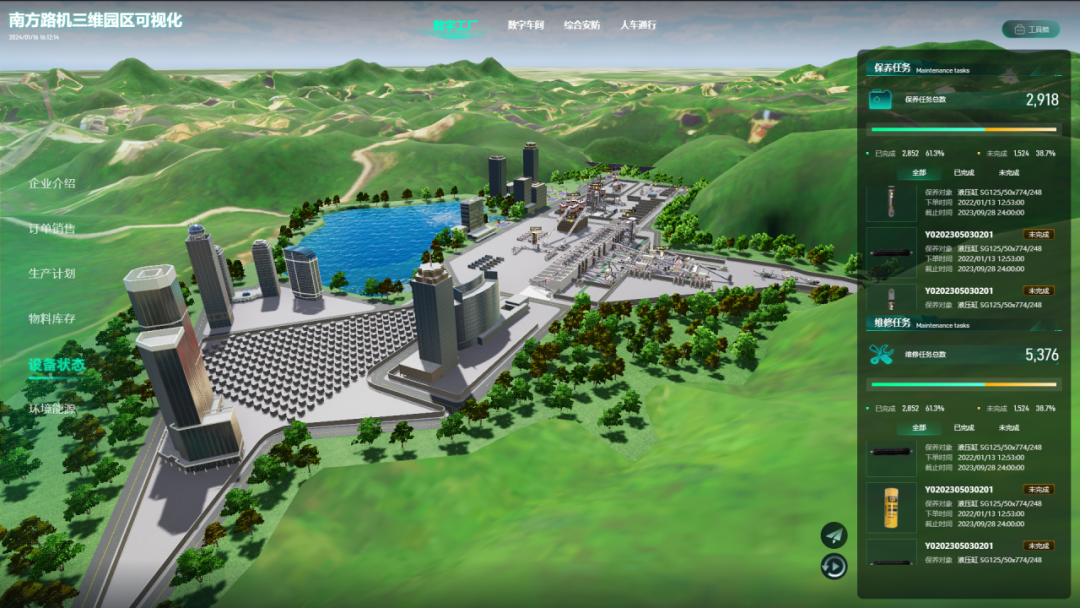

Construction of Digital Twin Factory Using Nanfang Road Machine Digital Twin Visualization System,The factory area can be realized、Workshop、Production line、Step-by-step visualization of equipment。Construction set production management、Equipment operation and maintenance、Integrated security、Warehousing logistics management、Energy efficiency management、Visual decision analysis and other business areas in one visual platform.,Realize data and information interaction between process nodes。Visual management of the integrated data of the production process、Analysis and mining,Provide the basis for decision-making,Realize full life cycle visualization、Datamation、Intelligent new mode。

The digital twin visualization system of Nanfang Road Machinery can be used to locate the factory area.、Distribution, etc. For visual detection,Integrate the existing data resources of the plant,On the production schedule、Product quality、Equipment operation and maintenance、Warehousing and logistics、Integrated security、Detection and analysis of key indicators such as energy efficiency management,Assist the manager to fully grasp the operation situation of the plant,RealizationThree-dimensional panoramic visualization and intelligent management and control of regulatory area。

Support the integration of production data of various products in the plant area,Yes, production plan、Planned output、Actual output、Visual monitoring of inventory, etc.,Support specific production line point selection and view,Real-time control of production data,Control the production schedule,Reduce operating costs,And that production efficiency is improve。

Using 3D modeling,The digital twin visualization system of Nanfang Road Machinery can truly reproduce the appearance and internal structure of equipment and facilities.、Operating conditions,Integrated video surveillance、Real-time information collection such as equipment operation monitoring,Monitor the situation of equipment operation and maintenance。At the same time,The system canQuickly identify potential risks and threats,Early detection of production component anomalies,Active alarm,Help enterprises find and solve problems in time,Improve the efficiency of operation and maintenance。

Device can be integrated with video surveillance system、Data of security management system in the plant area such as electronic patrol system,Visualization of plant safety situation。Support key parts of the plant area、Personnel、Real-time monitoring of Vehicles and other elements,Quick positioning、Real-time access to surveillance video, Help Improve plant safety management。

Support 3D visual modeling of warehouse space in the plant area。By 3D modeling,Three-dimensional display of the internal and external environment and internal space structure of the storage space in the plant area,Realistic reproduction of material stacking scene。Support partition monitoring for different types of stockpiled materials,Yes, mixed stacking、Visual alarm in case of insufficient materials in the material warehouse,Number the goods、Time of entry、Real-time query of detailed information such as inventory level。Realize the effective management and control of warehouse space in the factory area,Improve the supervision efficiency of various warehouses in the plant area,Optimize inventory management level,Reduce the cost of dead stock and material shortage。

Support the integration of plant energy consumption data,Fuel consumption in the plant area、Gas consumption、Real-time monitoring of the production and operation situation of each subsystem of energy consumption such as electricity consumption。Support for energy dispatch、Equipment operation、Multi-dimensional visual analysis of environmental monitoring and other elements,SupportEnergy consumption trend analysis,Help managers to understand the energy consumption status of the plant in real time,Rational allocation of resources、Provide strong data basis for energy saving and emission reduction in the plant area。

3D Digital Twin Visualization System of Nanfang Road Machine,Enabling the whole life cycle construction of smart factories,Provide strong support for long-term decision-making of enterprise managers。In the wave of digitalization and intellectualization,Digital twin technology will continue to lead innovation and change in the industry.,Help enterprises to remain invincible in the fierce market competition!