A year's plan begins in spring,At the beginning of the Year of the Dragon。In order to help users grasp the golden period of construction,Win the battle and make a good start to the year,Wittgen China, together with agents from all over the country, brings 2024 annual product technology national tour exchange activities to users across the country.。

Follow product experts to learn about Wirtgen's diversified high-performance road construction and maintenance products and technologies in China.,Appreciate“Smarter、Safer、Sustainable”A new trend in the industry。

What are the highlights of this year's tour??What dry goods do you have??What value can it bring??Don't hurry,Xiaowei, here is the Reuters for you.!

Move to be smarter、Safer、A sustainable future

As a leader in the field of road construction and maintenance equipment in China,Wittgen China has always been adhering to“Close to customers”The idea of,Relying on the Group's strong technological accumulation and innovation capabilities,Focus on product applications,Committed to building for users to meet future construction challenges、Road Construction and Maintenance Solutions to Enhance Competitiveness。

“Smarter、Safer、Sustainable”Is the vision of the Wirtgen Group,The R & D and listing of the new generation of Wittgen Group products are the full embodiment of this enterprise strategy.。On communication activities,Participants can be in the face-to-face explanation of product experts.,Close experience of Wittgen's road construction and maintenance equipment in China“Hard power”。

As the pioneer of milling technology,Wirtgen has a rich product line,From half-meter Milling Machine to one-meter Milling Machine、Medium-sized Milling Machine、Then to the large Milling Machine of 2 meters.,There are up to 10 Remaining new models of the fourth generation of China。

Whether pothole repair in narrow spaces,Or rapid maintenance of municipal roads?、Large-scale reconstruction of expressway;Or high-precision road leveling、Special applications such as step milling in expressway reconstruction and expansion,Can provide customers with a cost-effective and suitable choice.。

At the same time,The new models also feature Wittgen's innovative core cutting. 、Advanced technologies such as precise leveling and intelligent control,Achieve operational efficiency、While the accuracy and quality are significantly improved,Better construction economy and safety。The most important thing is,These models have been validated for very long hours of application,Performance and reliability have been tested by the market.,User feedback is well-known。

In terms of road paving and compacting equipment,There are more than ten new models in the four new product series of Vogler.,Overwrite 0.5 meters -18m paving width,It can fully meet the multi-function and multi-scenario application needs of Chinese customers.。

Fourth National Emission -The new 3 Series models all have Vogler's proven technical leadership,Such as ErgoPlus 3 Human-computer interaction intelligent control system、 Niveltronic Automatic Vertical and Horizontal Slope Control System and Leveling Sensor Technology、Intelligent Heating Control Technology of Screed,Flexible original screed configuration, etc.。

It not only continues Vogler's high-quality paving effect,,And the fourth national emission engine adopts the modern driving concept.,Through EcoPlus The energy saving and emission reduction package can further reduce fuel consumption and emissions.,Better meet the demands of Chinese customers for high economy。

Paver is the key factor to determine the construction progress and flatness of the surface layer.,The construction efficiency and compaction quality of Road Rollers also play an indispensable role in the service life of roads.。As a leader in road compaction,Hummer country four series roller is a highlight of the event site.。

A new generation of heavy double-drum roller HD 138 i / HD 148 i Substantial optimization of compaction parameters,Higher vibration frequencies and amplitudes result in higher compaction efficiency。

And the new generation HC Series 20-The 26 ton fully hydraulic single drum roller benefits from the ideal weight distribution of the front and rear axles.、Structural Design of Three-point Articulation、Full hydraulic drive and other advantages,Outstanding performance in terms of gradeability and compaction performance。

In addition,Thanks to the newly equipped Hummer. HAMMTRONIC Intelligent compaction control system、Both series of rollers have continuous control of the frequency of vibration、Anti-skid、Flexible start and stop of equipment、Compaction cruise constant speed、ECO Mode and a series of automatic control functions,The operation is safer,For the construction side to achieve a higher quality ideal compaction effect from the base to the surface.,Further reduce fuel consumption、Reduce emissions。

Innovation is based on application,Technology creates benefits

So what kind of help can these innovative technologies and products bring to users??With“Fourteen five”The advancement of planning,The pace of building a modern highway maintenance system has been accelerated.,The maintenance project is precise、Green maintenance and production are the future trends.,The future of facility digitization、Maintenance specialization、The requirements of efficient operation and other aspects will also be gradually improved.。

Under such a general trend,,How to achieve efficient operation,Meet the requirements of fine quality,As well as environmental and economic benefits,This is a common challenge for the road construction and maintenance industry.。

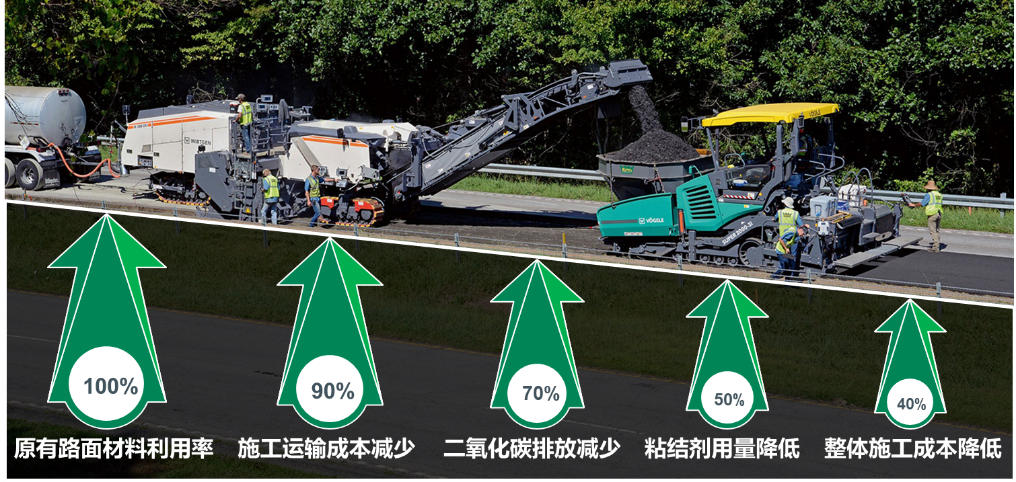

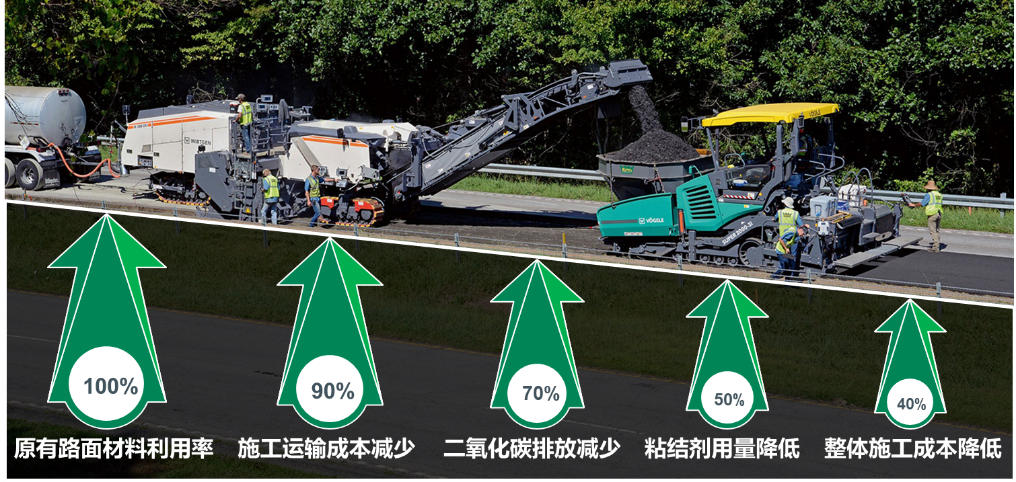

In addition to milling and pressing products,Participants will also have the opportunity to learn about the industry's cutting-edge pavement structural maintenance and road upgrading technology during the tour exchange activities.。Wirtgen's recycling construction technology adapted to various scenarios,The technical specialist will also lead the guests to have a look at Wittgen's high-performance on-site cold recycling equipment based on synchronous paving to improve the material utilization rate by 100 percent,At the same time, it can effectively reduce the overall construction cost and carbon emissions.。

And in that application field of highway accessory structure and road upgrade and reconstruction,,Use of Wirtgen Small Slip Form Paver SP 15i Application of Synchronous Forming and Paving of Various Small Cement Concrete Structural Parts,It has gradually replaced the traditional manual laying method and become the industry trend.,Participants can also learn about the advantages of this new construction method through on-site exchanges.。

Meet the aggregate demand of construction project,Kelei mobile aggregate processing technology has also brought new solutions for highway construction and construction projects.。

It is believed that through the introduction of experienced product application experts with Wittgen China at the event site,,In-depth communication with peers in the industry for practical application scenarios,Close observation of equipment performance display,Participants will be confused about the configuration of the aircraft fleet.、How to reduce cost and increase efficiency、As well as the problems encountered in the construction project.。