Early spring in March,The wind is gentle and the sun is warm,The two sessions ended as scheduled,Strengthening the Construction of Ecological Civilization,Promoting green and low-carbon development on the agenda,Be the center of attention。

Li Qiang, premier of the State Council, said in a government work report on the 5th.,We should strengthen the protection and management of the ecological environment.,Accelerating the Green Transformation of Development Mode,Coordinated promotion of carbon reduction、Reduce pollution、Expand the green、Growth,Building a Beautiful China with Harmonious Coexistence between Man and Nature。

Absorb carbon dioxide,Realization“Carbon neutral”The most important way is afforestation.,The most effective way is to save energy and reduce emissions.。

The report of Jiangsu Asphalt Pavement Thermal Recycling Engineering Research Center shows that:“Road doctor”Hot in-place recycling for every 1m2 of construction,Reduce carbon dioxide emissions by about 11% compared with traditional proces.3 kg,Equivalent to 0.The amount of carbon dioxide absorbed by one tree in one year,That is, 0 was planted.1 tree。If thermally regenerated half of a three lane road,Construction 1 km,Equivalent to planting 1000 trees(Note:Take a 30-year-old fir for example.,It can absorb 111 a year.kgCarbon Dioxide)。

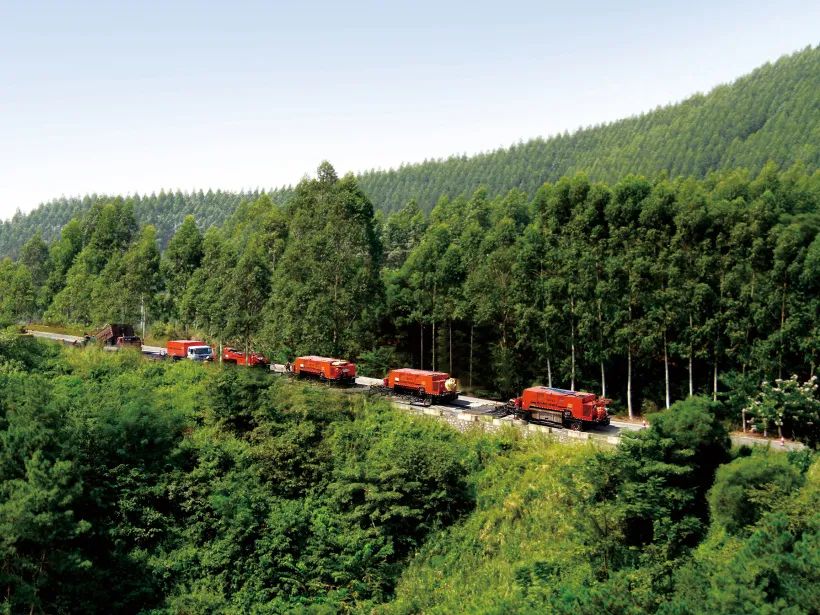

How to achieve efficient energy saving and emission reduction,“Afforestation”?The road doctor has his own.“Practice medicine”The Way。Over the years,Road maintenance equipment used by INTECH、Materials and technologies are green and energy-saving.、Meet the relevant national requirements for energy conservation and carbon reduction,Independent research and development of low-carbon and environmentally friendly hot in-place recycling equipment and technology,Do our best to protect the ecological environment。

Low-carbon and environment-friendly hot in-place recycling technology

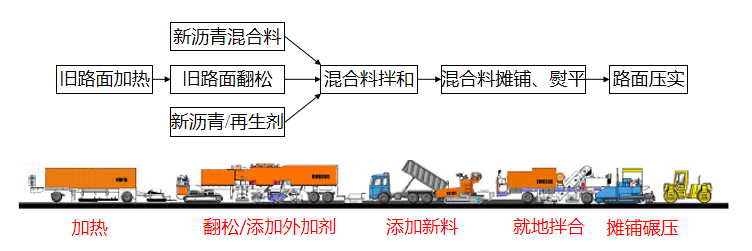

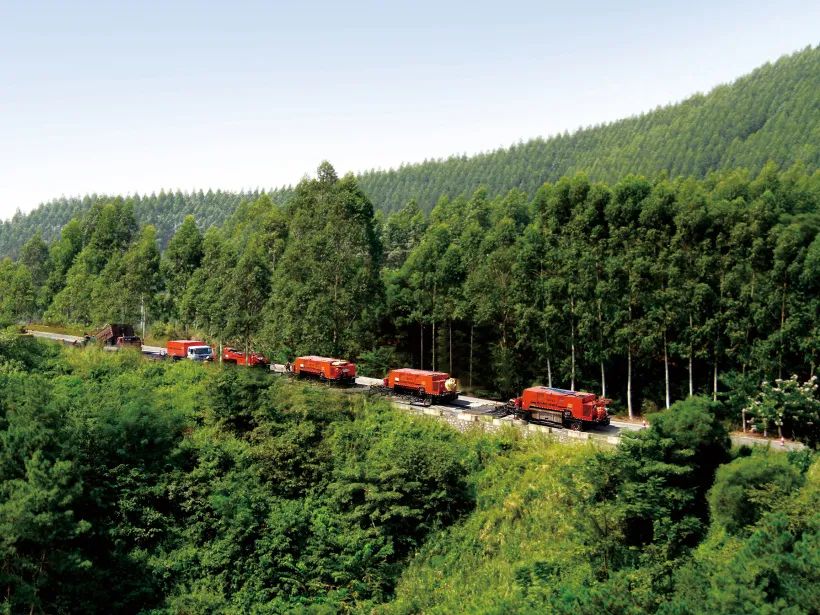

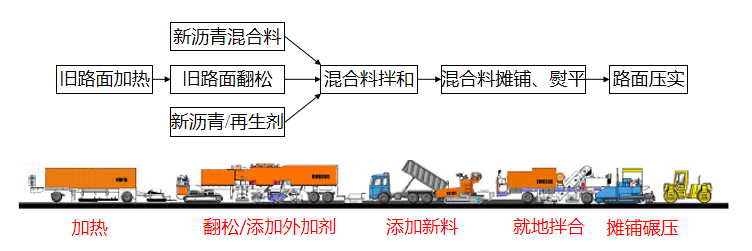

Intech Independently Develops Low-Carbon and Environmentally Friendly Hot In-Place Recycling Process,It can shorten the construction period、Reduce the transportation of waste materials、Cost saving、Reducing traffic impact and the like.,Can effectively solve various disease of that pavement,Comprehensively improve the quality of road traffic,Reached the green、Low carbon、Cycle、Civilized construction requirements such as environmental protection。

1

Pavement material 100%Reuse of original value

Traditional road maintenance to go through milling、Scrap removal、Pave new materials、Complicated steps such as transportation of waste materials,INTECH non-breaking aggregate technology,Truly realize the original pavement 100%Recycling and reuse of original value,To avoid the destruction of the ecological environment caused by a large number of quarries.,Fully in line with the reduction of circular economy、Requirements for resource utilization and reuse。

2

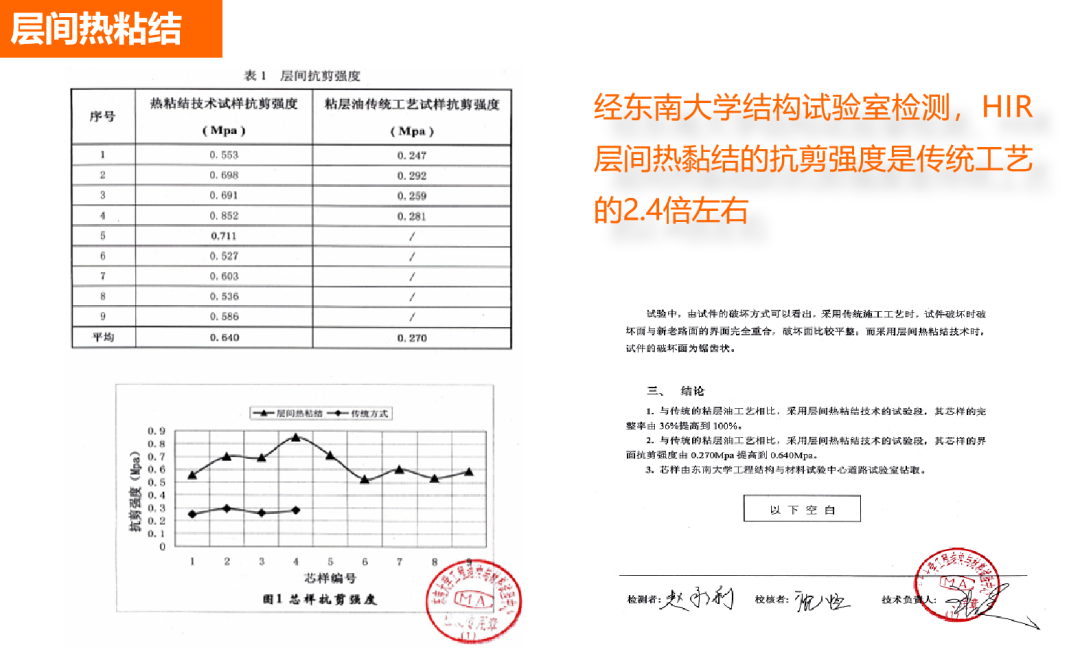

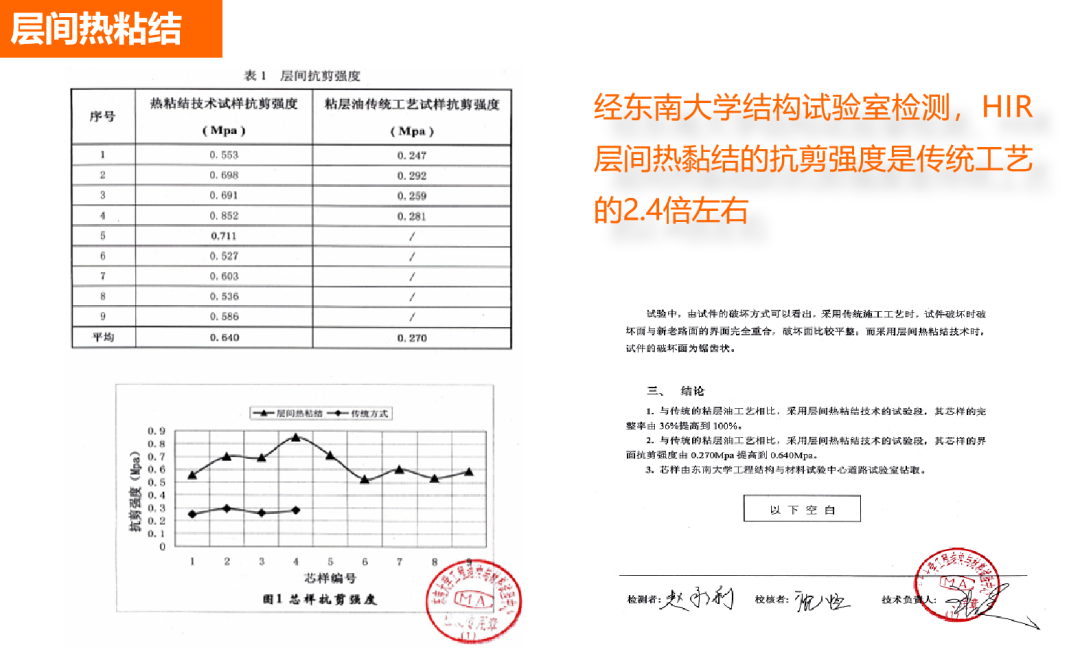

Thermal bonding between layers“High quality and environmental protection”The characteristics are obvious

Adopt the national patent intermittent thermal radiation heating technology,Ensure thermal bonding between the reclaimed layer and the lower layer,No weak joints、Weak interface,New and old materials are completely embedded and extruded,Compared with the traditional planing and milling paving process, the shear strength of the pavement is improved by more than 3 times.,Greatly increase the service life of pavement,Avoid the environmental impact caused by repeated maintenance。

3

Economic benefits、The social benefit is remarkable

Use“Thermal regeneration”Technology,The construction speed is 2% of the traditional technology-3 times,80% less than traditional proces%Carbon emissions;Not required after patching is completed“Rest period”,It only takes about 2 hours.,Road traffic can be resumed.。Really realize energy saving and emission reduction in the field of highway maintenance,Achieve the goal of low-carbon green scientific maintenance,Economy、The environmental protection benefit is remarkable。

Varied modular combination of equipment

The hot in-place recycling unit of Yingda was identified by the Ministry of Transport as“International leading”,Original and varied equipment and process combinations,Effectively deal with different types of road diseases、Cause of formation、Climate、Environment、Different governance needs caused by planning, etc.,The construction process is efficient、Quickly、No noise、No interference, etc. Green、Low carbon、Cycle、Civilized construction requirements such as environmental protection。

1

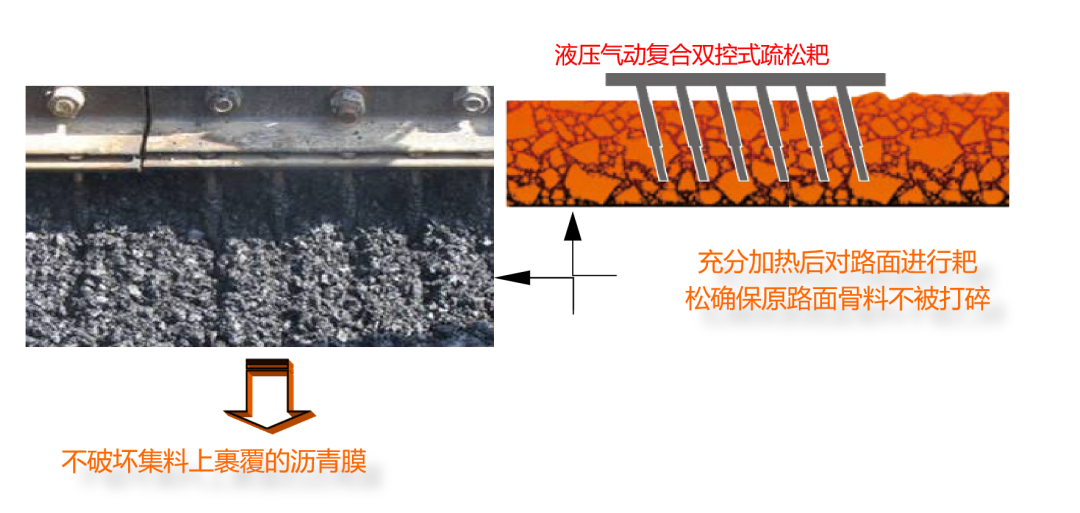

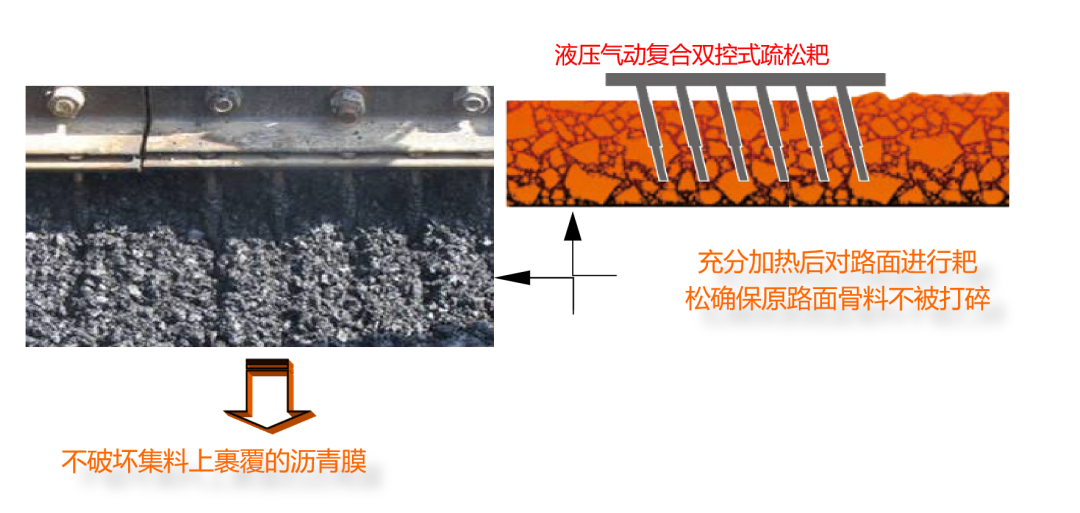

Do not break the aggregate,Improve pavement performance

Traditional planing and milling process produces a huge amount of toxic waste,It cannot be degraded naturally,Long-term environmental pollution,Milling cutter head is not used for INTECH maintenance equipment,Loosening the road surface by using multiple groups and rows of loosening harrows,Ensure that the aggregate is not broken,Improve pavement performance。At the same time, a large amount of dust generated in the construction process is avoided.,Do not add to the air“Haze”

2

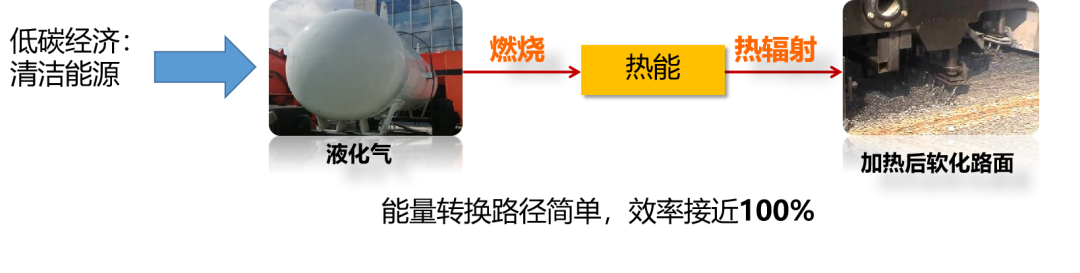

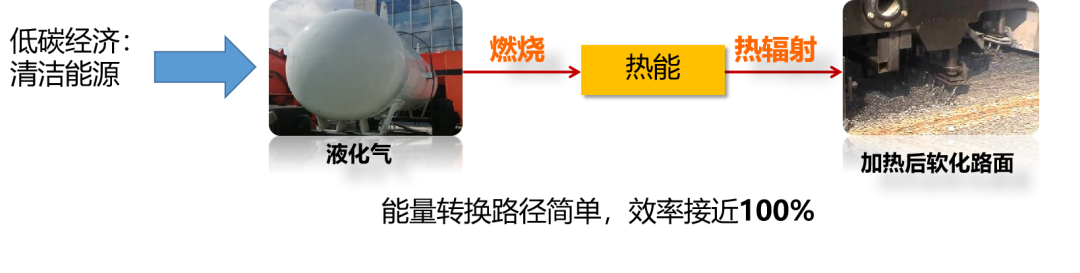

Use clean energy,Reduce carbon dioxide emissions

The construction process uses clean energy to heat the pavement.,Simple energy conversion path,Efficiency is close to 100%,Relative to conventional fossil fuel combustion,Reduce carbon dioxide emissions in a real sense。

3

Green、Low carbon、Construction requirements for environmental protection

The equipment is flexible,It can be transferred independently,Finish in 30 minutes.、Withdraw;Integrated construction of units,Only one lane is occupied during construction,There is no need for road closure,Quick transition,The construction process can minimize the impact of construction on road traffic pressure and public travel.。Completely in line with green、Low carbon、Cycle、Civilized construction requirements such as environmental protection。

Leading the road maintenance industry towards a green economy、Low-carbon economy、Circular Economy Development Yingda Technology Group Continues to Surpass Itself,The Power Source of Pursuing Excellence。So far,The total construction area of Yingda Technology Group is over 95 million square meters.,Reduce carbon emissions by 1.5 million tons,Equivalent to planting 10 million trees!Highway Doctors Take Practical Actions to Protect the Environment and Home for Future Generations!

On the occasion of the 30th anniversary of the founding of INTECH Technology Group,We're on“Road doctor”Low Carbon Action Plan。This is not just a simple plan to save energy and reduce emissions.,It is also a long-term plan for the benefit of future generations.。

We promise:Future,The Group achieved an annual construction area of20%Increment of,New within five yearsReduce carbon emissions by 1.07 million tons,(Equivalent to)9.6 million trees were planted;In ten years.Reduce carbon emissions by 2.5 million tons,Realization23 million trees were planted,Reforestation of 80000 mu!A more beautiful planet for future generations.!