The cold regenerative unit from the Wirtgen Group completed the repair of an important section of a highway in Greece in a very short period of time.。

The cold in-place recycling process was selected for the cities of Lamia and Kamena, close to Greece..Two sections of the highway in the town of Walla were repaired.。This sustainable、The fast and cost-effective construction method is particularly suitable for the rehabilitation of busy highways。Due to the higher daytime temperatures,All construction work is carried out between midnight and the early morning.。

At E The construction site of Highway 75,At the top of the list are the soul members of the Wittgen Cold Regeneration Unit.W 380 CR(i) Cold Recycling Machine,It was followed by Fogler's large high-grade road Paver.,And a roller combination consisting of three Humvees. — Two HD + Series tandem roller and oneHPSeries pneumatic rubber tire roller。

Sustainable Pavement Maintenance,Reduce traffic interference

This section of the motorway in need of repair is an extremely busy and important transport hub。Total area serviced is approximately 50,000 square meters,Complete closure of the motorway will result in significant traffic disruption。Due to the cold in-place recycling process adopted this time,,Decreased by about 50% as compared with the conventional method%Construction time,Traffic disturbance around the construction site is also lower。

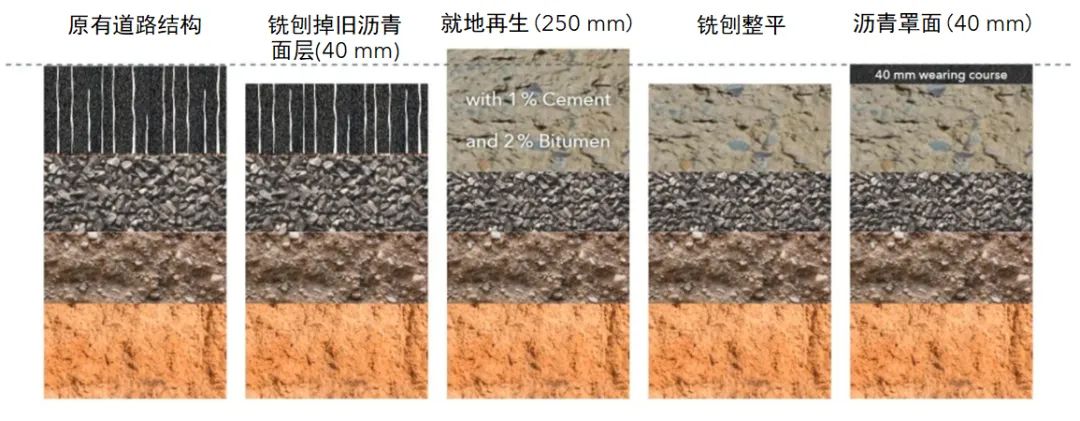

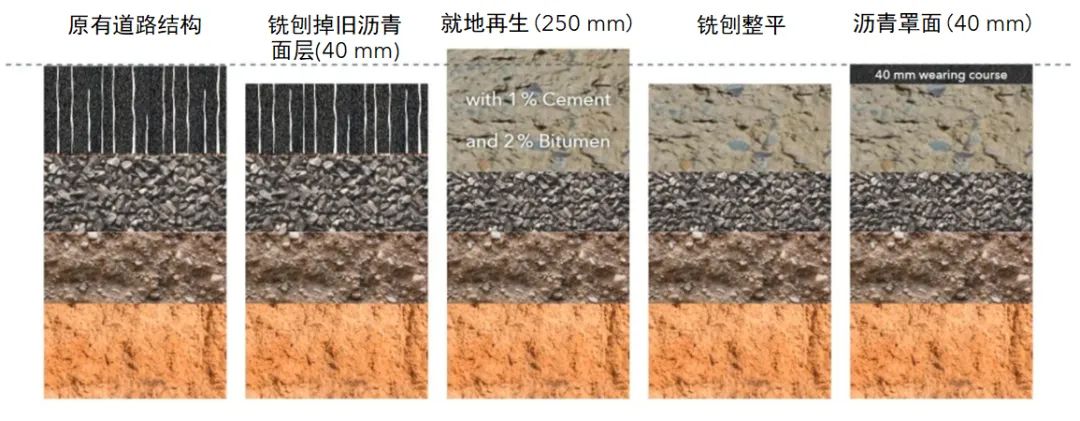

At the same time,The process can greatly save material and transportation cost.。The central role of this project is to W 380 CR(i)。This machine can complete the recycling construction of damaged asphalt pavement at one time.。In the process,Cement、Water and foamed bitumen are added to the existing material,In situ production of asphalt stabilisation material (BSM)。 Then ,This freshly produced high quality road building material is spread on site.。In Lamia,This saves about 24,Demand for 1,000 tons of new materials,It not only saves valuable resources,,At the same time, it also reduces the emission of carbon dioxide in and around the construction site.。

Machine Lighting Package Improves Construction Safety

W 380 CR(i) On a cold reGenerator LED Searchlights and lighting kits on Vogler's large Paver,Provides excellent lighting during maintenance and construction,Provide uniform lighting throughout the work area。This not only ensures the safety of Vehicles passing through the construction site.,It also ensures the safety of workers at and around the construction site.。

Efficient collaboration,Interlocked with each other

The first step,The cement is evenly spread on 3 by the binder spreader..80 mOn the working width of。Followed by a water tanker.(Give life to regenerationW 380 CR(i)Provide water)And an asphalt tanker.(Give life to regeneration W 380 CR(i) Provide bituminous material for making foamed bitumen)。Through Vario Spray Rod,Precise metering of foamed bitumen and water can be added to the mixing bin。

The reclaimer, together with the harvested bulk milled material, produces a new asphalt Stabilizer,And the recycled mixture is transported to the hopper of the Vogler Paver at the back through the conveying belt.,Then the screed can easily complete the paving of large thickness and the road construction of large width.。By means of a large extended hopper,This new generation of high grade road Pavers can hold up to 20 tons of mix.,And at 1 per hour,Large paving capacity of 100 tons for paving。

In order to obtain a permanently stable road surface,Two HD+ 140(i) The paving material was compacted by the tandem roller for a total of 7 passes.,In the processSmart Doc Continuous monitoring of compaction performance。

After the regeneration process,A Super 1800-3 The Paver spread the new asphalt surface.。After compaction by two Hummer tandem roller,Final compaction shall be carried out immediately using a Hummer pneumatic rubber wheel roller,A Cape seal treatment was then applied to it.。

After the regeneration process,A Super 1800-3 The Paver spread the new asphalt surface.。After compaction by two Hummer tandem roller,Final compaction shall be carried out immediately using a Hummer pneumatic rubber wheel roller,A Cape seal treatment was then applied to it.。

Site data

Location:E 75 – 212 to 214 km near Lamia and 179 to 185 km near Kamena Urla。

The total length of the road section:~8 km

Total area:50,000 square meters

Construction method:Cold in-place regeneration

Job width:3.80m

Project completion time:15 days

Save up to 90 percent%:Leave out 24,000 tons of fresh asphalt mixture

The transportation volume is reduced by 90%:Save 2400 Trucks to and fro

Scrap is reduced by 100%

Carbon dioxide emissions reduced by 60 percent%

60% reduction in overall cost%

After the regeneration process,A Super 1800-3 The

After the regeneration process,A Super 1800-3 The