In recent years,Domestic large-scale open-pit mining projects of 10 million tons are increasing.。According to the survey of China Coal Industry Association,As of September 2023,China has built 52 ten-million-ton coal mines.,The approved annual production capacity of super-large single coal mines has exceeded 40 million tons.。Vehicles running in the mine must be controlled under the condition of safe density.,Mine owners want to improve transportation efficiency and production efficiency,The short-term solution is only to enable large mining Trucks.。

And actually,At present, the load capacity of common off-highway wide-body dump Trucks active in domestic mines is only 70-90 tons,Really meet the efficient transportation needs of mine owners,It's actually Caterpillar、Large 100-ton rigid mining Trucks produced by Komatsu and other foreign manufacturers,The purchase and maintenance costs of these imported Vehicles have remained high for a long time.,Vehicle production and delivery cycle is very long,Even if domestic manufacturers have launched similar models.,Its core important components still rely on foreign technology and supply chain.。This has become a common dilemma for many mine owners and whole machine factories.,It has seriously affected the progress of transformation and upgrading of mines in China.。

Large new energy rigid mining Truck produced by iridium molybdenum technologyEM165H

Recently,Xiamen Iridium Molybdenum Technology Co., Ltd.(Hereinafter referred to as“Iridium Molybdenum Technology”)Launch of large new energy rigid mining TruckEM165H,Standard deadweight up to 115 tons,It is 1% of the load of traditional Vehicles.5x,Realize the Breakthrough of Large-scale Domestic Mining Truck。Iridium Molybdenum Technology through the domestic pioneering 8×6 Multi-axis drive+Head and tail multi-axle steering scheme、Relying on the advantages of domestic industrial chain,The load of the Vehicle is greatly increased and the intelligent and flexible distribution of the power system is realized.,At the same time, the cost is greatly reduced and controlled.,It provides a clear and effective way for large mining Trucks to fully usher in the era of localization.。

The market urgently calls for large domestic mining Trucks to upgrade the efficient transportation of mines

According to the author's research,At present, most of the mines active in China are traditional 6.×4 Off-highway wide-body dump Truck,This type of Vehicle has a load range limited by its technology.,Basically concentrated at 70-90 tons can't break through.,In the face of China's ten-million-ton mine exploitation“The new normal”,It is difficult to keep up with the pace of development.;And 4×2 Rigid Mining Truck,The load of mainstream models is 100-300 tons,It can meet the needs of mine development in China.,However, the technology and supply chain required for this route,It has been restricted by the barriers built by foreign main engine factories and suppliers for a long time.,The cost of imports is very high.,Production delivery、The subsequent maintenance is also accompanied by a series of problems.。

Co-founder of Iridium Molybdenum Technology&Li Kerui, chief technology officer

Co-founder of Iridium Molybdenum Technology&Chief Technology Officer Li Kerui introduced.:“Traditional mining Trucks are limited by the number of drive axles,Limited load capacity;If more weight is required,It also needs to be equipped with larger engines and gearboxes.,Inability to avoid foreign supply chains,This has brought great difficulties to the localization of large mining Trucks.。”

Large-scale upgrade of mine transportation equipment in China is the direction of policy、The needs of the times,Is it because“Stuck in the neck”Stuck in a difficult situation?Iridium Molybdenum Technology gives the answer.!In order to solve the inherent technical difficulties,This technology company has a unique way to innovate independently.,Launch of China-made 200-ton large mining TruckEM165H。

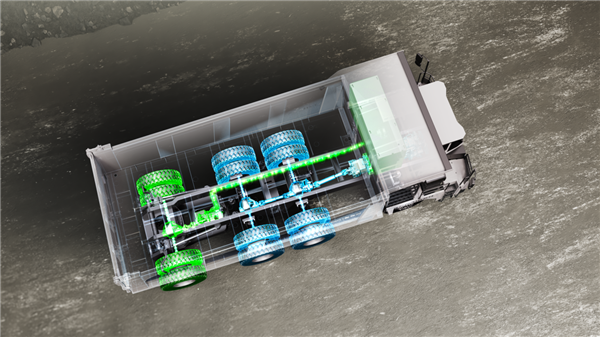

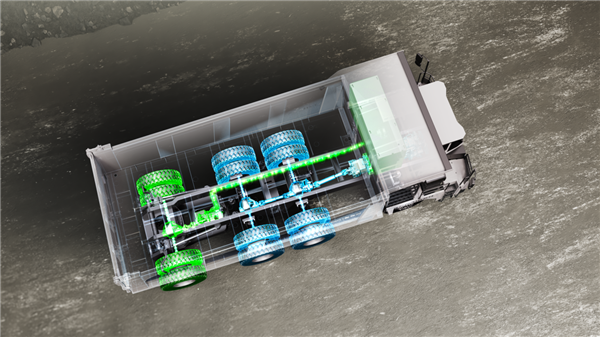

It is reported that,EM165HAdopted the 8 developed by the pure direction×6 Distributed drive scheme,With multi-axis drive+Head-tail multi-axle steering feature,Iridium Molybdenum Technology is the first technology company in China to propose this technology route and complete the landing.。EM165HUnder the scheme design,One more load-bearing bridge can effectively disperse the load of the whole Vehicle.,While achieving a load capacity of 115 tons,,Bypasses the need for large single component,The whole Vehicle can be manufactured by domestic supply chain.,Completely break the foreign“Stuck in the neck”Limitations。

Mining Trucks as a means of production,Not only“Dora”You have to“ Run fast ”In order to create greater benefits for the owners.。Comparison 6×4 Traditional scheme,EM165HTwo middle axles and one rear axle are used as drive axles at the same time,And the front and rear axles can complete active steering.,Such a complex synergy depends onEM165HRealization of powerful intelligent control system。Through Vehicle data monitoring and analysis,EM165HIt can intelligently identify different working conditions and driving conditions,And thus control that start and stop of various module units.、Flexible distribution of power ratio、Achieve simultaneous head and tail steering,So that that Vehicle can go up and down the slope、Turn、A bumpy road,Always maintain the optimum driving speed without excessive driver operation,So as to shorten the time of each trip.。

Iridium Molybdenum TechnologyEM165HThe launch of,It is an important stage achievement in the battle of large-scale technology for domestic mining Trucks.,It is the strong call of the market for a long time.“Respond”,It is a landmark event for all miners.。

Efficient、Fuel saving、Good value for money EM165HReal car performance is excellent

Mining Trucks are high-load equipment designed and manufactured specifically for mine haulage.,It often operates in the complex terrain and working environment of the mining area.,And need to maintain stability and transportation efficiency。As a newly launched large domestic Mining Truck,,EM165HHow does it perform??Whether it can withstand the severe challenges of the harsh working conditions of the mine?

It is understood that,EM165HAfter going off the production line, they arrived at three mining areas respectively for marshalling operation test.,These include the most complex domestic working conditions recognized by the industry.、A mining area in Wuhai, Inner Mongolia with the worst conditions。Iridium Molybdenum Technology also sent a special technical service team to the mine to track the operation of Vehicles at close range.,Once problems are found, they should be rectified immediately.。According to the test,EM165HWhen overloaded to 150 tons,Still available at 28%Drive normally on the slope.;EM165HIt can also easily handle all kinds of bumpy roads.、Take a sharp turn;Since the beginning of 2023,Each unit has been continuously tested for more than 1 year.,It has experienced a low temperature of minus 30 degrees and a high temperature of nearly 40 degrees.,Under extremely severe transportation conditions,Still holding 95.%Attendance。

A large new energy Mining Truck running in a mineEM165H

AtEM165HWhen it was first launched,Iridium Molybdenum Technology takes a free trial or test drive to let customers feel the performance of the Vehicle on the spot.。According to the actual trial feedback of the mine owner,TwoEM165HThe traffic volume is basically equivalent to three common models on the market.,They made a simple calculation.,Under the same mining area,Produced using iridium molybdenum technology.EM165HAchieve the same production capacity of common models,“Reduction of Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicles by one third,The matching Excavator is correspondingly less.,Spending on drivers and field operators who need to be matched has been cut by a third or even half.,Think again, it is more and more difficult to recruit drivers in mines now.,Wage costs are getting higher and higher,All kinds of invisible expenditures are saved.,It's worth it anyway.。”

Not only that,EM165HAdopt oil-electric hybrid drive mode,Through intelligent power management、Intelligent energy-saving system implements Vehicle monitoring、Administration、Adjust the deployment,Not only can the energy loss be fully reduced,,But also can recover the braking energy when the vehicle goes downhill for a long time to improve the energy utilization rate of the vehicle.,A full haul can save at least 20 percent%Fuel costs。“We also found that,Under the common working conditions of short haul distance and small height difference,EM165HFuel-saving performance is more prominent,Fuel saving 30%Even 40%It's all possible.。Reduction of fuel costs by at least one fifth,Combined with reductions in other categories of expenditure,The cost of putting in a car,Must be recovered in less than two years。”

On the other hand,Compared with imported Mining Truck ,EM165HOne third or half of the price.,AndEM165HUnique head-tail multi-axle steering technology makes the vehicle more flexible,The user does not need additional on-site implementation of the transformation cost.,That is to say, it can realize more green and efficient large-scale Mining Truck transportation on the basis of existing lanes.。Dora, run!,Good value for money,EM165HWith outstanding transport efficiency、The excellent performance and remarkable oil-saving effect have been unanimously affirmed by the owners of the trial mines.,Successfully dispelled the purchase concerns of many owners.。

It is reported that,Produced by Iridium Molybdenum TechnologyEM165HWith excellent real car performance,In 2023, it has been fully recognized by early customers.,The layout of key areas will be completed rapidly in 2024.。

Persisting in Technological Innovation and Breaking through Large-scale Barriers EM165HResearch and development is revealed

As a scientific and technological innovative enterprise,The founders of Iridium Molybdenum Technology are all from the Department of Automotive Engineering, Tsinghua University.,He has more than 15 years of experience in building cars.,They led the iridium molybdenum technology team to stay in the front line of the mining area for a long time.,Maintain close cooperation with mining enterprises and engineering construction teams,In addition, he has been engaged in the research and development of underground mining construction machinery and new energy passenger cars for many years.、Design、Production and sales,Be able to integrate relevant technologies and experience,It is used to solve practical problems in mining areas.,“The superposition of all these factors,It is the key for Iridium Molybdenum Technology to take the lead in achieving breakthroughs in large-scale domestic Mining Trucks.。”Li Kerui said。

It is understood that,EM165HIs Iridium Molybdenum technology based on the cloud.HiMADSThe first product launched by the platform。And the cloudHiMADSIt is a multi-bridge new energy rigid wire-controlled mining card platform developed by Iridium Molybdenum Technology.,Is a common technical architecture,Iridium Molybdenum Technology is the basis for the development of all future models.。The platform is driven by innovative multi-axis head and tail multi-axis steering technology.,Achieve greater chassis capacity to support higher loads and more agile steering,Breaking through the load capacity of domestic Mining Trucks to 115-200 tons。

Cloud trenchHiMADSPlatform multi-axis distributed drive technology

Not only that,It is a large transport equipment directly facing the mining area.、Efficient、Wisdom、Green、Integrated Change Challenges for Security,Cloud trenchHiMADSPlatform innovation brings together multiple underlying technologies,Modularization of different functions and systems,The integration characteristics of this complex hardware combination,Deciding intelligent control is its essential characteristic.。Cloud platform uses intelligent multi-controller domain control architecture to achieve complex multi-module system collaboration.,Divide the vehicle functions into power domain、Chassis domain、Cockpit area、Autopilot domain,And that network information of each domain is uniformly manage by the central gateway,Realize the optimal allocation of resources。

In addition, power coupling and intelligent power management system,As a dynamical system“ Brain ”,It can accurately identify the operating conditions and adopt different output strategies.,Make each shaft distribute power flexibly,Adapt to uphill and downhill、Unload、Difficulty relief and other needs;Hydro-pneumatic suspension system、Energy Smart System、Vehicle networking system and data analysis platform,The flexible shock absorption stabilizes the body、Energy loss reduction recovery、They all play a vital role in vehicle remote scheduling.。

It was revealed,AtEM165HAfter,260 tons of iridium molybdenum technology development、Large Mining Trucks such as 185 tons are also about to go to the mining area.,They are all based on the cloud.HiMADSPlatform design。This creative modular technology design architecture,It not only helps Iridium Molybdenum Technology to achieve rapid development of new models,,Significantly reduce procurement、Repair、Maintenance costs,But also accord to that environment and development planning of different mine areas of customers.,On the basis of meeting large-scale,Intelligent options suitable for unmanned driving,Mine Owner Responds to Country“Constructing Zero Carbon Intelligent Mine”Call、Large-scale mine transportation equipment、Unmanned upgrade will become leisurely and clear path。

Large-scale technology and supply chain have long been limited by foreign countries.,It is an important reason why large Mining Trucks in China can not be fully localized.,This solid barrier that all miners have been unable to overcome has been successfully opened by iridium molybdenum technology.。And more cases are proving to us.,Facing the great changes in the increasingly fierce international competition,Only by innovation and struggle can we take the initiative in complex situations.。With the domestic large Mining Trucks gradually mounted on the stage of history.,It is believed that iridium molybdenum technology will bring more efficiency to mine owners in China in the future.、Wisdom、Safe、Green Transportation Solutions,In the age of new energy,There will be new forces in the field of construction machinery.,To subvert orPKTraditional manufacturing players,Help the whole industry to move towards a broader and better future。