Recently,Wirtgen Based on Synchronous Paving W 380 CR For the first time, the cold Recycling Machine successfully applied the cold recycling method of emulsified asphalt in Guangxi to realize the restoration of national and provincial trunk roads。W 380 CR Reclaimed fleet with side pre-milling,The half-width road 6 is realized at one time..2 m Width regeneration,Once again, it reflects the high efficiency and flexibility of this regeneration process for a variety of application scenarios.。

It also shows that W 380 CR Diversified construction capacity of local cold Recycling Machine,It is not only competent for cold regeneration of foamed asphalt、Cement cold regeneration,It is also suitable for cold recycling of emulsified asphalt.,It provides a variety of feasible schemes for green low-carbon road maintenance.。

Project overview

This project is a pavement service capacity improvement project of Guangxi general national and provincial trunk highway in the new western land-sea corridor.G324 Asphalt Pavement Overhaul Project of Baiyin-Xinzhou Section in Tiandong County,Total length approx. 10 km,The project is about 10 meters away from Tiandong County km,About 70 from downtown Baise km。

The road section has been opened to traffic.,With the rapid development of regional economy,,The traffic volume has also increased rapidly.。In recent years, with the gradual increase of traffic flow and overweight Vehicles,,Plus rain、The erosion of natural disasters such as floods leads to the continuous emergence of pavement diseases.,Road conditions are deteriorating.,The old road surface has been cracked by blocks.、Cracking、Rut、Transverse crack、Longitudinal cracks and other main diseases,Affect the safe operation of the highway。While reducing driving comfort,It also causes the increasing cost of highway maintenance and social Vehicle operation.。

The purpose of this overhaul is to improve the capacity of the road,Improve the traffic appearance of villages and towns along the line,Better serve the residents along the line.,Enhance the development capacity and speed of regional economy。

Application scheme

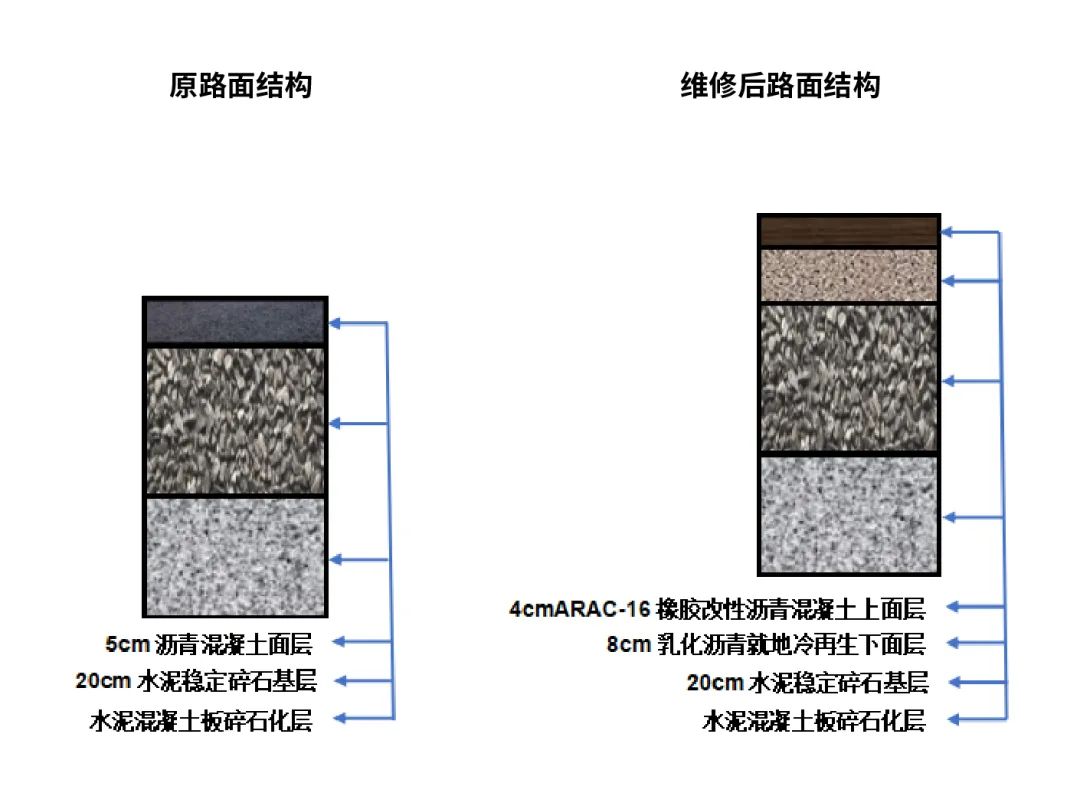

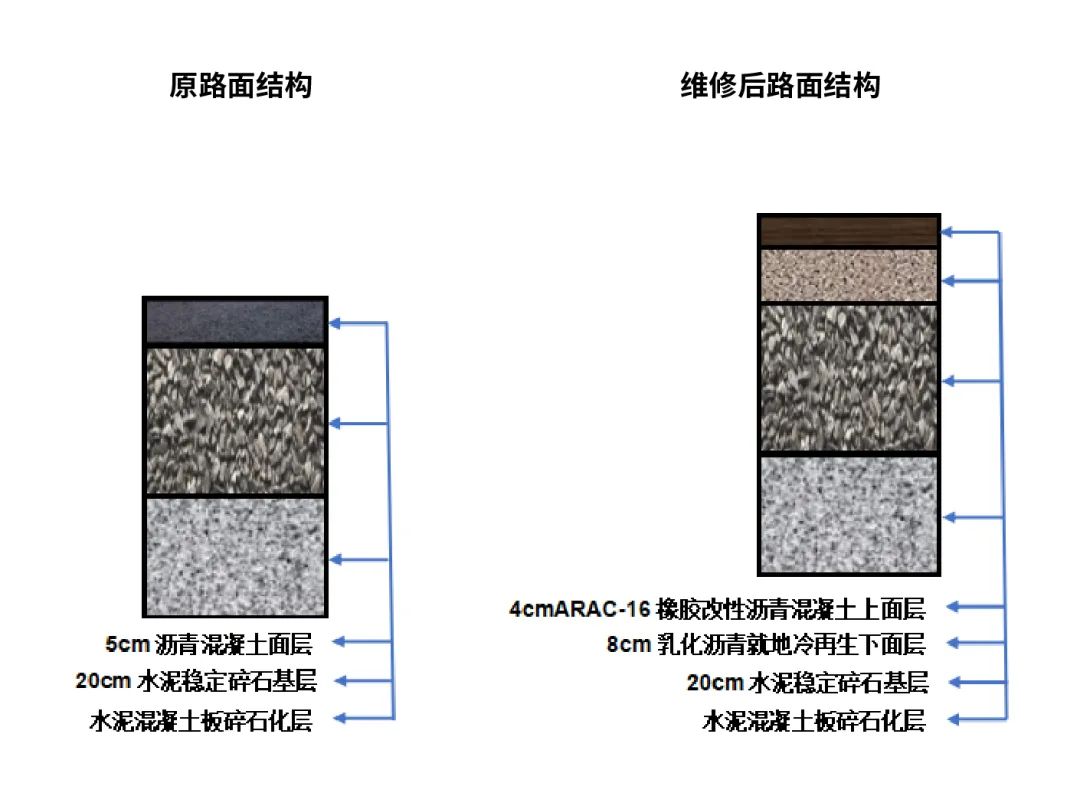

Use Wittgen directly W 380 CR Cold Reclaimer Pair Original 5 cm Asphalt concrete surface course(Add some new materials)Carry out in-situ cold regeneration of emulsified asphalt,Generate 8 cm Thick cold recycled layer of emulsified asphalt is used as the lower surface layer.,Finally, add 4 on top. cm ARAC-16 Upper layer of rubber asphalt concrete。

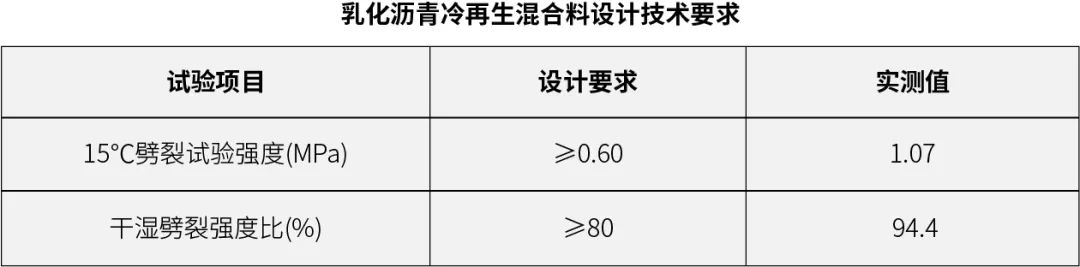

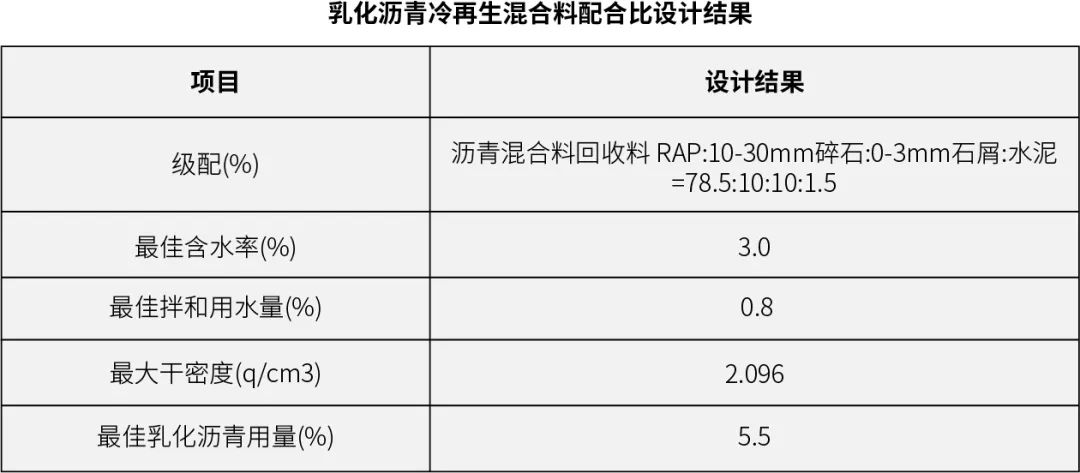

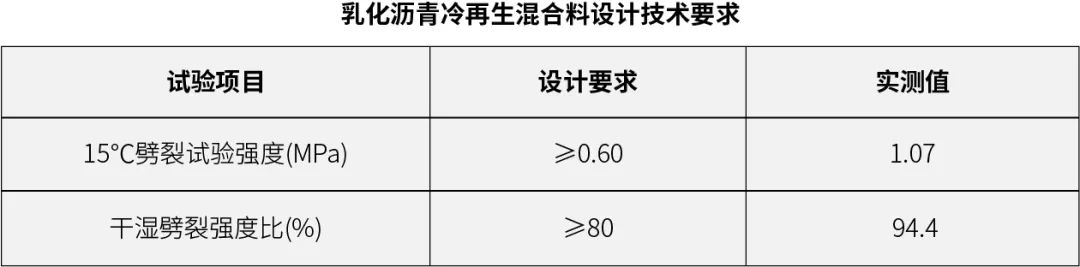

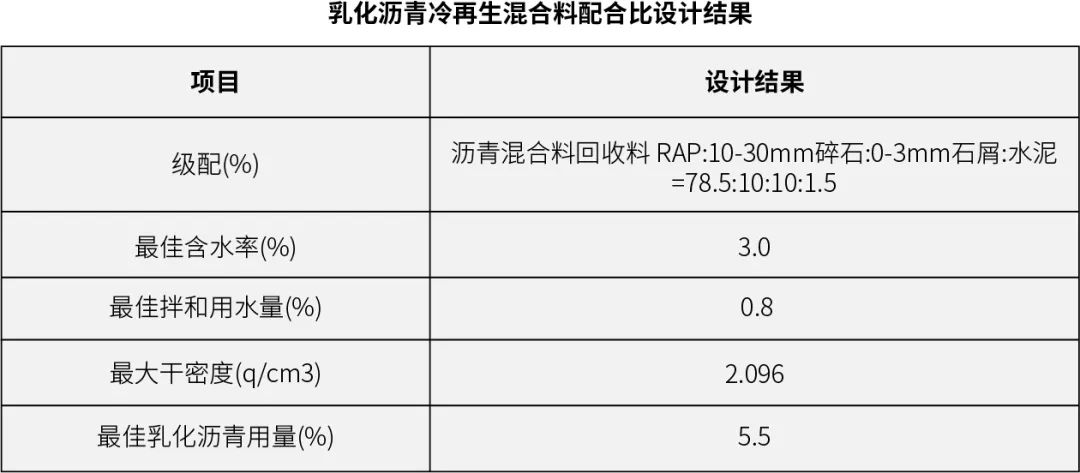

Mix proportion design

Construction process

Adopt half-width construction,Construction organization scheme for half-width passage。The construction width of half width is 6.2 m,Exceeded W 380 CR Cold Reclaimer 3.8 m Reclamation operation width of,Therefore, it is necessary to adopt the side pre-milling and widening construction technology.:

1.A Wittgen 2 was used m Milling Machine and a Wittgen 0.5 m Milling Machine,Forward the cold regeneration to the right 2.5 m Pre-milling of wide old asphalt layer material,The milling material is discharged to the remaining 3 of the half width by the conveying belt.7 m Within the width area;

2.The newly added crushed stone and stone chips are then spread by an aggregate spreader,(1 pressed:1 proportion is well mixed in advance)Evenly spread on the milled material;

3.And then the cement to be added is accurately and uniformly spread on the newly added aggregate by using a powder spreading Vehicle.;

4.And then W 380 CR The cold reGenerator leaves a width of 3..7 m,5 thick cm The old asphalt layer material is milled and crushed.,Mix in pre-milled bituminous layer material and pre-spread fresh aggregate and cement,At the same time, advanced functions W 380 CR Cold Reclaimer spray system will emulsify asphalt and water accurately.、Add it evenly.,And finally mixing to form a uniform emulsified asphalt cold recycling mixture;

5.Conveyed by the conveying belt at the rear of the reGenerator to the hopper of the Vogler spreader at the rear,Full and half width by Paver 6.2 m Paving,Finally, it is rolled and formed by Hummer roller.。The rolling sequence is:Static compaction by double-drum vibratory roller for 1 time、Vibrating and pressing once(Initial pressure)→Vibrating and compacting by single drum vibratory roller for 3 times(Repressing)→Static pressure of rubber-tired roller for 6 times(Final pressure);

6.Curing of cold regeneration layer。

Since the implementation of the project,,W 380 CR The daily completed quantities of the cold Recycling Machine are about 8000~10000 m²(Half width approx. 1.2~1.5 km),The high efficiency and stability of the equipment have been affirmed by the owner and the general conTractor.。

The aggregate of the core sample taken on site is evenly distributed.,The porosity is small,Very dense

Cold regeneration generalist W 380 CR

Adopted this time W 380 CR The first successful application of cold Recycling Machine for cold in-place recycling of emulsified asphalt in Guangxi provincial trunk line,Proved W 380 CR The cold Recycling Machine can not only successfully complete the construction of cold recycling of foamed asphalt and cement, which we are familiar with.,It is also competent for on-site cold recycling of emulsified asphalt.,He is a well-deserved versatile player.。

Based on synchronous paving technology W 380 CR Cold in-place recycling technology has low carbon、Efficient、High performance and many other advantages,It will be applicable to more application scenarios in Guangxi pavement maintenance market.,Add a beautiful stroke to the colorful oil painting composition of pavement construction!

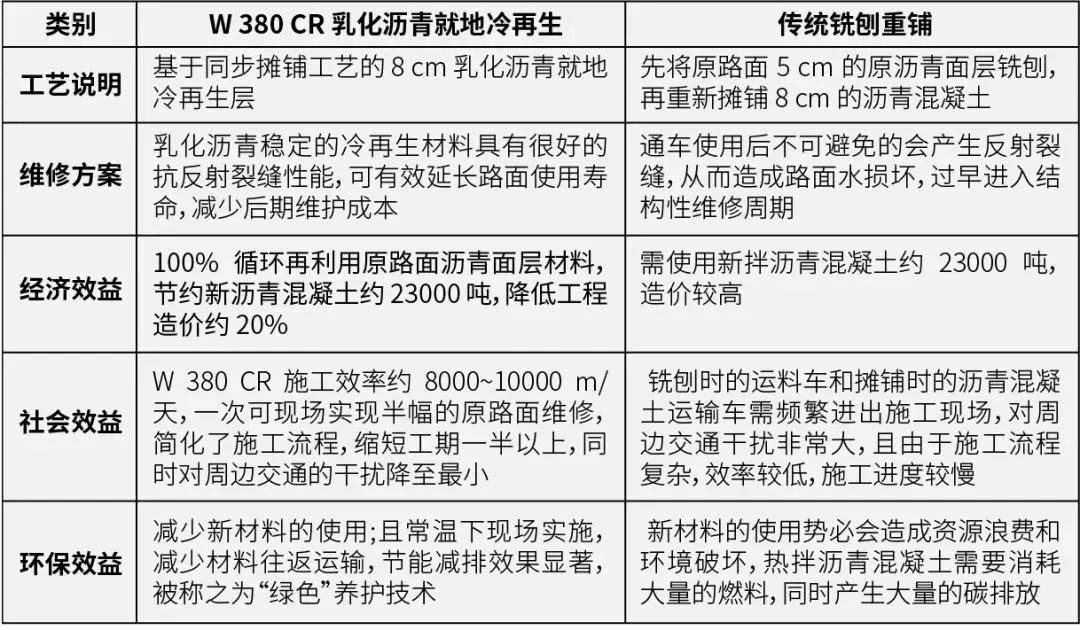

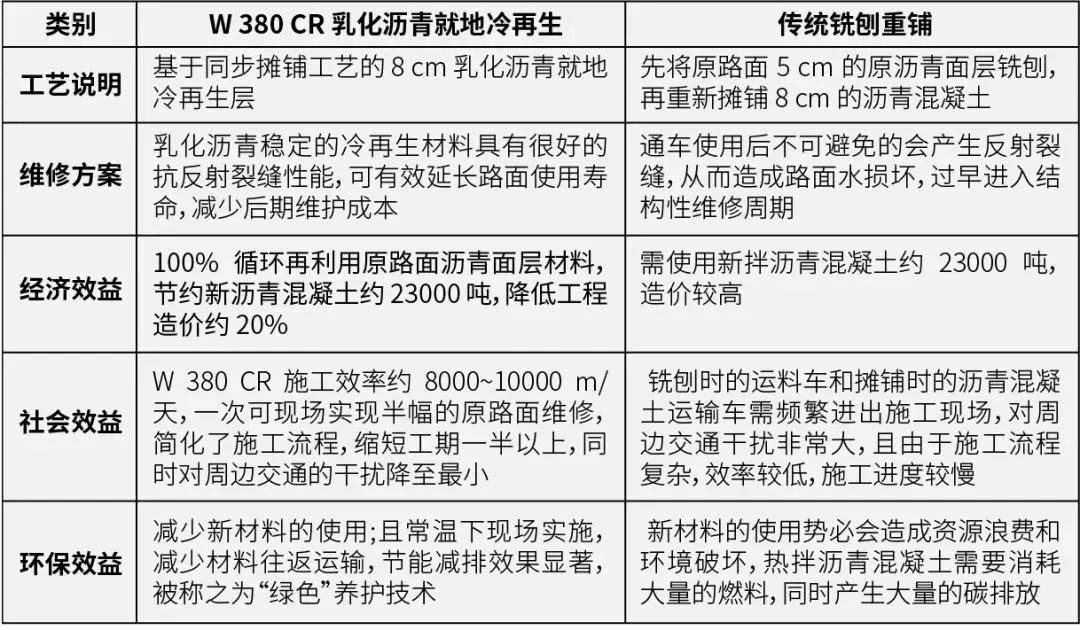

Advantage analysis and comparison