In the foundation leveling project of a port in Fujian,Two MesidaLarge-scale mobile crushing and screening production linePut into use,The hourly output of a single line is 250-350 tons,Average daily production capacity of 5000-6000 tons,Exceed customer's expected output。

Project background

The project site is the largest bulk cargo terminal in the port.,Water depth conditions are good.、Great location。It has a 150,000-ton general berth.(The wharf structure is designed as per 200,000-ton bulk carrier.),The total length of the coastline is 422 meters.,Designed annual throughput capacity of 4.35 million tons。

The enclosed area within the fence of the port area is 330,000 square meters.,Including 220000 square meters of storage yard、Four square warehouses,It covers an area of 40000 square meters、The maintenance garage is 3050 square meters。

Project overview

Site leveling construction project of the port wharf earthwork disposal project,The total amount of earthwork is about 30 million tons.,The construction period is expected to be 4 years.,The treated stone is granite.,Maximum particle size of material 800mm。

Before equipment mobilization,The terrain of the project site is surrounded by mountains.,The site is uneven,The road is not smooth,Initial construction and excavation of the mountain,Space is limited,Access roads are restricted。It is necessary to move the crushing production line to enter the site first for surface stone treatment in the early stage of the mine.,Level the ground,Road construction,As well as the foundation materials for installation and fixation in the later stage of production and the construction materials for the required site.。

Four kinds of finished aggregates are required for sand and stone aggregate,Respectively:0-5mm、5-10mm、10-20mm、20-31.5mm。Daily production capacity:4000 tons-5000 tons。

Project requirements

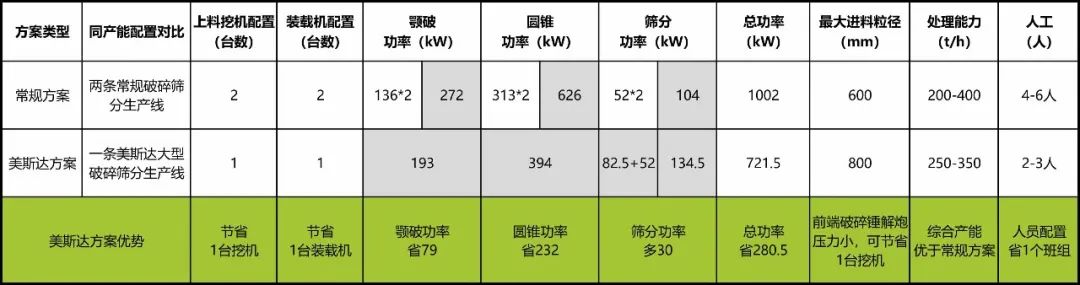

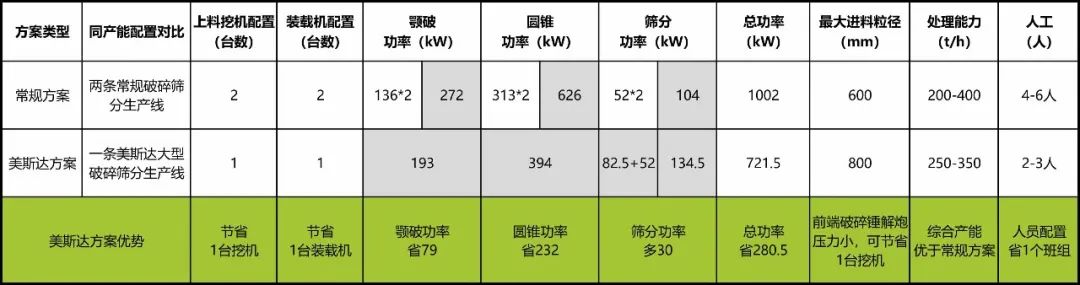

The conTractor of the project has configured two conventional mobile crushing production lines according to the requirements of the owner.,But the effect is not so good.,Due to various factors, the production capacity can not meet the project progress and project needs.,Therefore, customers hope to improve production capacity through better solutions.,Advance the construction period。

Over the years, Mestar has rich operational experience in many large-scale projects at home and abroad and has achieved good results.,Customer reputation and reputation is very good,Therefore, after the customer has a detailed understanding of Mestar,,The final choice is provided by Mestar.Scheme of large mobile crushing and screening production line,And introduce two sets at one time.。Configured as:

MC-120J+MC-450C+MC-6020H+MCP-6018B

Production line advantage

The production line isLarge production gold portfolio,Suitable for crushing and screening of all rocks,Unafraid of any hard quarry.。Uch as iron ore、Copper Mine、Granite、Basalt, etc。It is mainly used in large mines.、Quarry and infrastructure projects。

Integrated hourly capacity 250-350 tons。The processing capacity of the production line is large,The yield is high,Horizontal screen with large screen surface,And that screen rate is high,The material is high。

Because the output is large,The cost of overall input and apportionment is small.,And that economic benefit is high,Very competitive,It is an ideal choice for large-scale projects.。

Artificial 、Equipment、Fuel consumption and electric quantity、Operation and maintenance costs are reduced by 50 percent%

Capacity of conventional crushing and screening production line 100-200t/h,To meet 250-350t/hProduction capacity,At least two conventional production lines and two operation teams are required for completion.。

The project chose the technical solution given by Mestar.,JustA large mobile crushing and screening production line,Configure an operation team,It can operate efficiently。

Its labor input、Equipment、Fuel consumption and electric quantity、Operation and maintenance costs are reduced by half.。In terms of transfer transportation,Reduces transportation costs for multiple pieces of equipment。

In addition, Mestar has this articleLarge mobile crushing and screening production line can handle 800mmMaterial with large particle size,Reatly reducing the explosion pressure of the secondary Excavator breaking hammer of the front end blasting material,The input of at least one Excavator breaking hammer can be reduced.,At the same time, corresponding Excavator operators are reduced.、Equipment oil cost and operation and maintenance cost。

Large feed、High quality、High yield

Mestar's experience in design and manufacture of professional mobile Crusher,The design is optimizedLarge mobile production lineOverall structural strength,Fficient and scientific vibration reduction,Design of stress relief, etc.,It can guarantee to give full play to the performance advantages of the equipment host。

Optimizing cavity design,Base on that realization of larger fee particle sizes,Intelligent continuous feeding system support,Make the material flow of the whole production line more scientific、 Reasonable 、Efficient,The material gradation produced is more excellent.,RealizedLarge feed、High quality、Large-scale mobile crushing production with high output。

Transition spiritLive

Adjust the equipment position flexibly according to the construction site conditions.,Flexible combination and matching,Flexible collocation,Change at any time,Track movement breaks the restrictions on site requirements,Close to material operation,Reduce the cost of material transportation。Maximize economic benefits for customers,Flexibility to move broken,Fill in the shortage of fixed broken。

The stability is strong

Equipment usedABB、Schneider、Rexroth、Supply of excellent electrical components,Electrical Control Element、High standard spare parts for hydraulic accessories,Highly integrated control system,Simple but not simple,And that maintenance is convenient,The failure rate is low,So that the device can last for a long time,Stable and efficient operation,Provide safety production guarantee for production capacity。

Energy saving and environmental protection

The device is in electric drive mode.,Green and energy-saving,Economic and environmental protection,Zero emission、Zero pollution。Each material transfer point on the equipment is provided with a dust suppression spray system.,Reduce dust in production operation。

After the Mestar equipment is put into use,Two shift operation,The production is stable,Production capacity has been greatly increased,The hourly output of a single line is 250-350 tons,Average daily processing capacity of 5000-6000 tons,Exceed customer's expected output。At the same time, Mestar service engineers are stationed at the construction site 24 hours a day.,All-weather escort for customers。

Customer testimonials

From the preliminary scheme design of the project、Site investigation,Mestar is always attentive to our needs.,And accord to that physical characteristics of the material,、Abrasiveness and breakage values give us the best recommendation。Not only is the output large,The performance is good,Maintenance is simple,In particular, the feeding control of its continuous feeding system can ensure that the Crusher can give full play to its ideal capacity.。

Mestar after-sales service team from equipment mobilization to installation and commissioning,Equipment operation training、Safety production is provided in a timely manner.、Major、Comprehensive support and services。Provide strong support and guarantee for the rapid and formal commissioning of the project。

The above is from the heart of the project leader.。Customer to Mestar equipment and team and pre-sales、On sale、After-sales service is very recognized。And said:“Mestar has solved the production capacity problem for us.,So that the project can proceed smoothly.,Mestar gives us peace of mind、 Don't worry 、Peace of mind!”