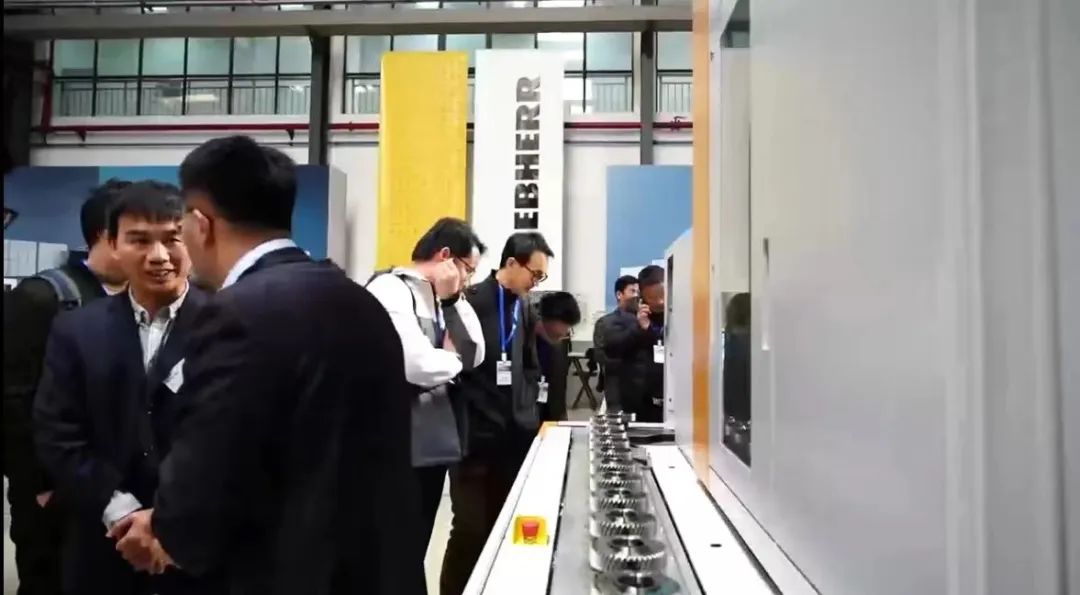

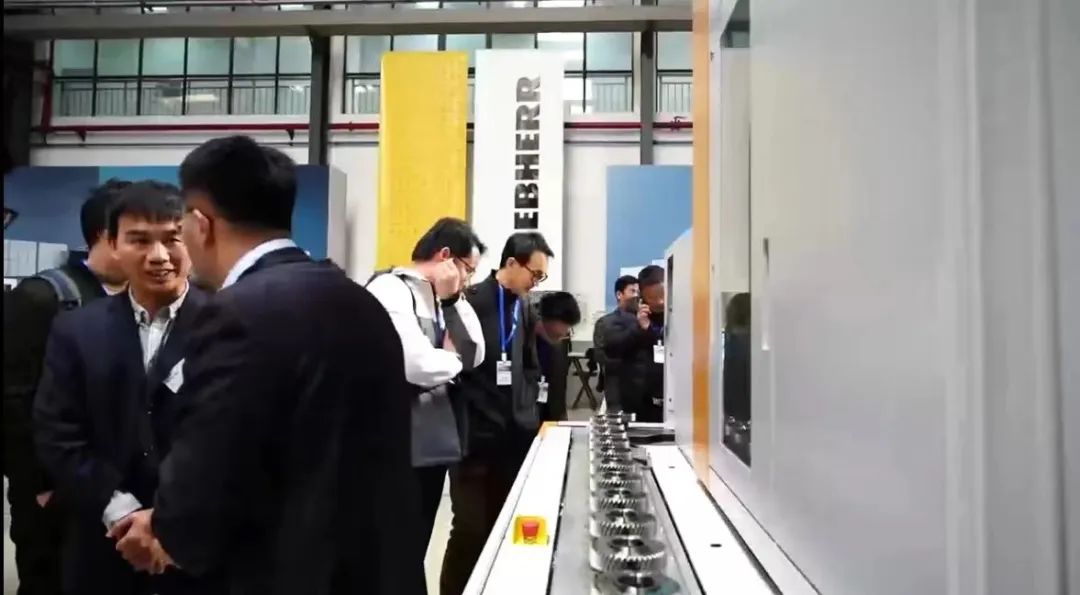

December 12, 2023-Thirteen,Liebherr's Yongchuan factory in Chongqing has invited a group of distinguished guests.,Liebherr gear machine tools from all over the world&Automation product users and technical specialist.,Gather factories to talk about the development prospects of gear processing technology for new energy Vehicles,At the same time, it is explained by professional technicians.,A more intuitive and in-depth understanding of Liebherr's star products in recent years,And industry-leading innovations。

▲ A video takes you to understand the atmosphere of the factory open day.

Liebherr China Gear Machine&Mr. Feng Haitian, General Manager of Automation Division, sent his sincere condolences to the distinguished guests present.,Thank you all for your continued support of Liebherr.!It also introduces the history of Liebherr China and Liebherr Gear Technology Germany.,And strong technical strength。

Liebherr China Gear Machine&Automation Division

Mr. Feng Haitian, General Manager

In addition, the event also invited the general manager of Liebherr China, Mr. Barrick, to deliver a welcome speech.,He passed on the spirit of the shareholders.:We aim to shape long-term industry trends,Make the impossible possible for our customers.,Make our life simple.。

Mr. Berrick, General Manager of Liebherr China

Recognition by customers and experts

Gear Processing Equipment plays a decisive role in gear accuracy.

Factory open day site,All the guests present agreed that high-precision gears will become the development trend of new energy Vehicle transmission system.。Especially, it has strict standards for gear processing technology.。

The importance of gear accuracy to new energy Vehicles is reflected in many aspects.:

And that transmission efficiency is improve

High precision gear can reduce the friction and energy loss in the transmission process.,So that that transmission efficiency is improve。This is crucial for new energy Vehicles that require high efficiency.,Contribute to improving the energy efficiency of the whole Vehicle。

Reduce noise and vibration

The tooth profile and pitch of high-precision gears are precisely calculated and optimized,So that that gear are more stable in the meshing proces,Reduce noise and vibration。This will improve the ride comfort of new energy Vehicles.NVH(Noise、Vibration、Acoustic roughness)Performance is of great significance。

Ensure safety

The gear transmission system of new energy Vehicles needs to withstand the test of high torque and high speed.,High precision gear has high strength and durability.,It can ensure the safe and reliable operation of the transmission system.。

And the service life is prolonged

The manufacturing process and material selection of high-precision gears are strictly controlled.,O that the gear has a longer service life.。This is of great significance for reducing the maintenance cost of new energy Vehicles and improving the economy of Vehicles.。

To meet the special needs of new energy Vehicles

New energy Vehicles put forward higher requirements for gear transmission system.,Uch as higher torque density,、Wider operating range, etc.。High precision gears can meet these special needs.,Provide strong support for the development of new energy Vehicles。

If the above five criteria are to be met,,

It is also a big challenge for gear processing technology and equipment.。

Make a very small mistake,A thousand miles apart

A workman wants to do his work well.,You must first sharpen your tools.

From gear measurement to cutting, an important closed loop is formed, which plays a key role in the accuracy of gear processing.。

In the development and processing of gear products,Measured by precise gear,We can find and correct the possible errors in the process of processing in time.,Continuous improvement of processing parameters,Until the product reaches the qualified standard.。At the stage of stable production,We control and test the quality of our products.,And adjusting the processing parameters in time according to the measurement result,To ensure that the gear products produced always maintain high precision and high quality.。

The new driving technology in the field of electric Vehicles is accelerating iteration.,This brings about a change in the market requirements for the accuracy and process improvement of gear components.。

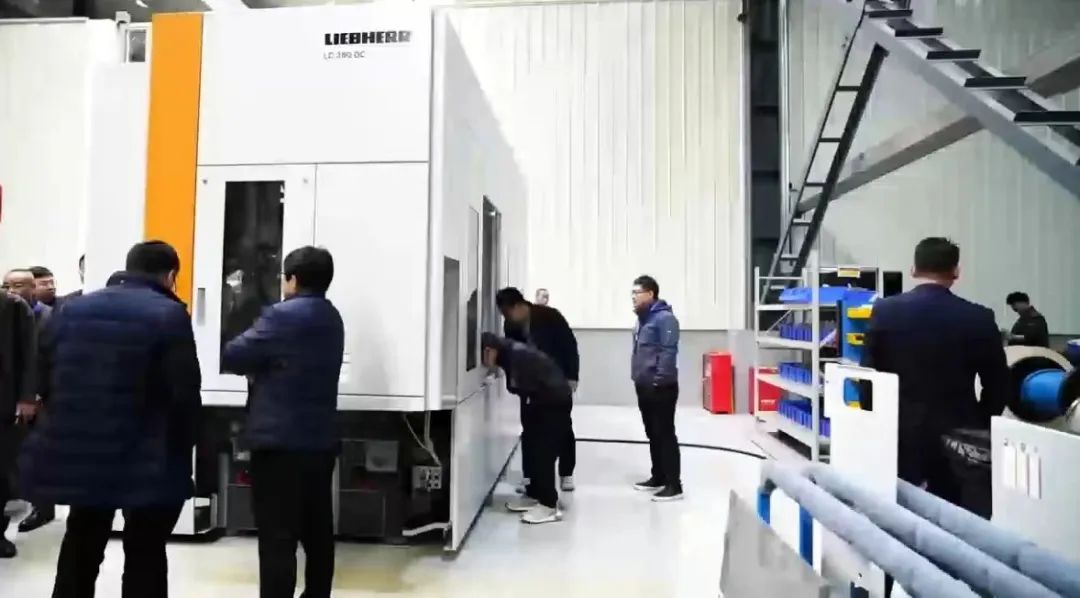

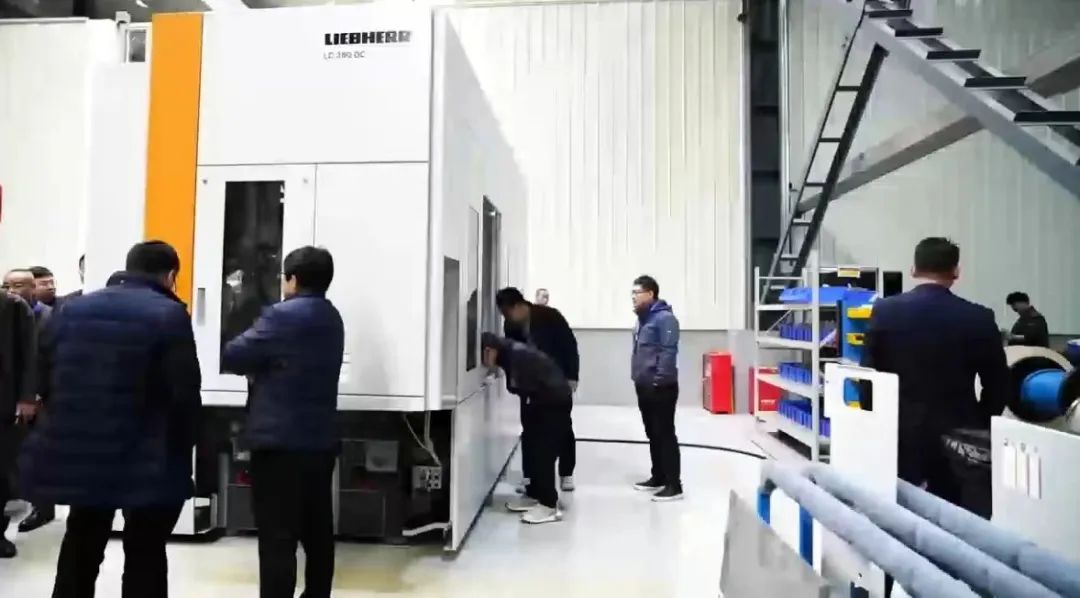

This open day,

Liebherr Exhibits Star ProductsGear grinding machineLGG 280

▼

Gear hobbing machineLC 280 DC

▼

Gear measuring machineWGT 400

▼

Since the official opening of Yongchuan factory in 2019,,Liebherr has always been committed to providing faster and better services to Chinese users.。The production center is used for hobbing and gear grinding machine assembly.,This will help Liebherr get closer to Chinese customers.,Thereby shortening the delivery time.。