Building materials industry in Zhejiang Province

Promotion meeting of new technologies for energy saving and carbon reduction

Zhejiang Province Building Materials Industry Energy Conservation and Carbon Reduction New Technology Promotion Conference

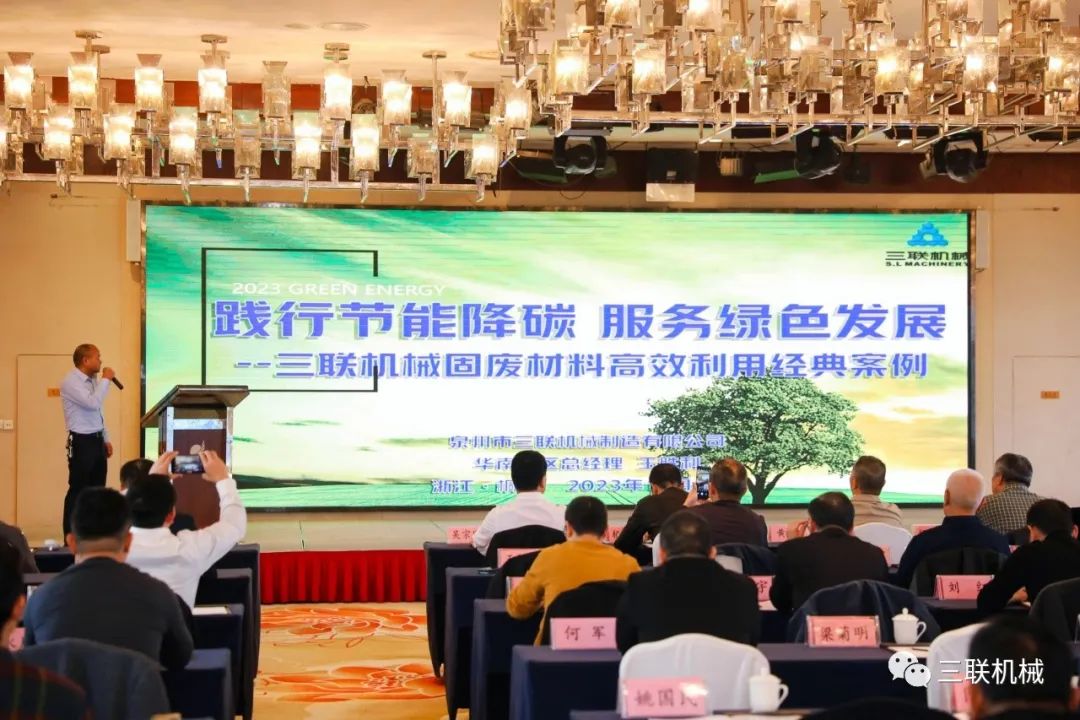

November 15, 2023-The 16th,To implement the green manufacturing policy in the industrial field.,Accelerate advanced energy-saving and carbon-reducing technology、Promotion and application of technology and equipment,Promoting the green and low-carbon development of building materials industry in Zhejiang Province is the main goal.,Sponsored by the Department of Economy and Information Technology of Zhejiang Province,Provincial Technology Innovation Service Center、Provincial New Wall Material Industry Association、Zhejiang Building Materials Industry Energy Saving and Carbon Reduction New Technology Promotion Conference sponsored by Tonglu County Economic and Information Bureau,Held in Tonglu。

On November 15-16, 2023, with the main goal of implementing the green manufacturing policy in the industrial field, accelerating the promotion and application of advanced energy-saving and carbon reduction processes, technologies, and equipment, and promoting the green and low-carbon development of the building materials industry in Zhejiang Province, the Zhejiang Provincial Department of Economy and Information Technology hosted the Zhejiang Provincial Technology Innovation Service Center, the Provincial New Wall Materials Industry Association, and the Tonglu County Bureau of Economy and Information Technology, Held in Tonglu.

Quanzhou Sanlian Machinery Manufacturing Co., Ltd. attended the meeting as a co-sponsor.。

Quanzhou Sanlian Machinery Manufacturing Co., Ltd. attended this meeting as a co-organizer.

Practice energy saving and carbon reduction

Practice energy conservation and carbon reduction

Wang Shengli, general manager of Sanlian Machinery in South China,“Practice energy saving and carbon reduction,Serve green development”Speech on the theme。This presentation begins with the role of new solid waste materials in the circular economy.,Domestic waste was introduced to the delegates.、Construction waste、Tailings、Current situation and development of various solid wastes such as washing sand and mud。The actual customer case shows the fully automatic servo vibration of triple machinery.、Advantages of integrated press production line for solid waste disposal。

Wang Shengli, General Manager of Sanlian Machinery in South China, delivered a speech with the theme of "practicing energy conservation and carbon reduction, serving green development". This speech starts with the role of new solid waste materials in the circular economy, and introduces the current situation and development of various solid waste such as household waste, construction waste, tailings, and sand washing mud to the attending representatives. The advantages of the production line of the fully automatic servo vibration and pressure integrated machine for solid waste disposal were demonstrated through actual customer cases.

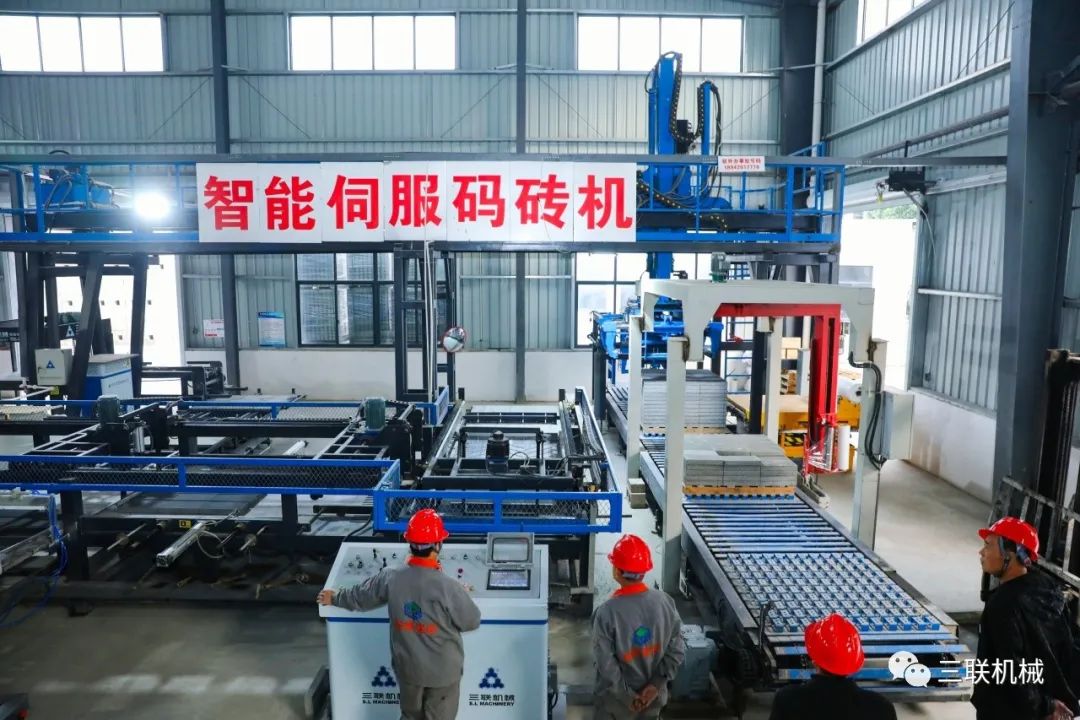

Triple mechanical full-automatic servo vibration、The press integrated machine production line is specially developed for various solid waste materials.,Once launched in 2020, the market will be rapidly expanded.。This series of products is based onSLST2000-500TBest seller,Adopt high efficiency servo vibration、Servo hydraulic system,The maximum pressure of the master cylinder can reach 500T,O that the product is firmer in the molding process.,The strength of the formed product is higher.,At the same time, it can meet the molding requirements of special brick shapes.。The main structure is cast as a whole.,Stable and reliable;Shaping mode: both vibration and pressure,Uarantee high compactness of product、High strength;Fastest molding cycle 12S,Forming parameters can be set according to different brick types.,The whole machine runs intelligently、Efficient、Energy saving,Noise reduction,Closed-loop production of complete production line、The movement is smooth,It is the best choice for making bricks from solid wastes。

The Sanlian Machinery of the fully automatic servo vibration and pressure integrated machine of the Triple Machinery is specially developed for various solid waste materials. It quickly spread to the market as soon as it was launched in 2020. This series of products is the best-selling among SLST2000-500T, using an efficient servo vibration and servo hydraulic system. The maximum pressure of the main cylinder can reach 500T, making the product more reliable during the molding process. The strength of the product after molding is higher, and it can meet the molding requirements of special brick shapes. The main structure adopts a casting form as a whole, which is stable and reliable; The forming method is both vibration and compression, ensuring high density and strength of the product; The fastest molding cycle is 12 seconds, and molding parameters can be set according to different brick types. The entire machine runs intelligently, efficiently, energy-saving, noise reducing, and the entire production line is closed-loop production with smooth movements. It is the best choice for solid waste brick making.

Serve green development

Service Green Development

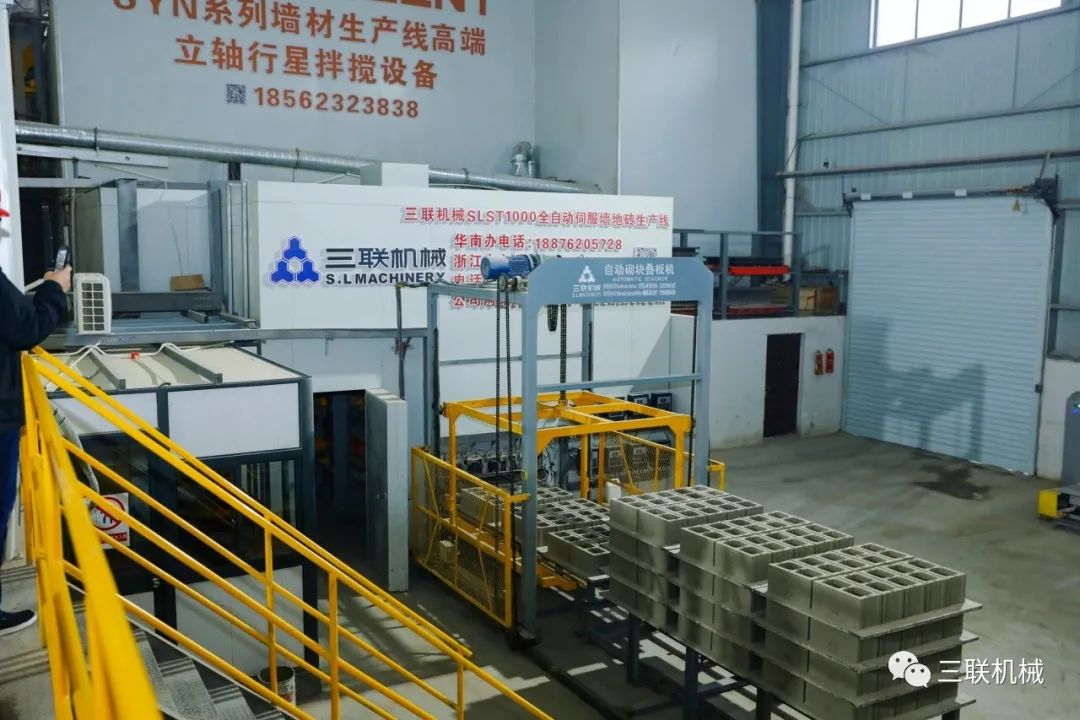

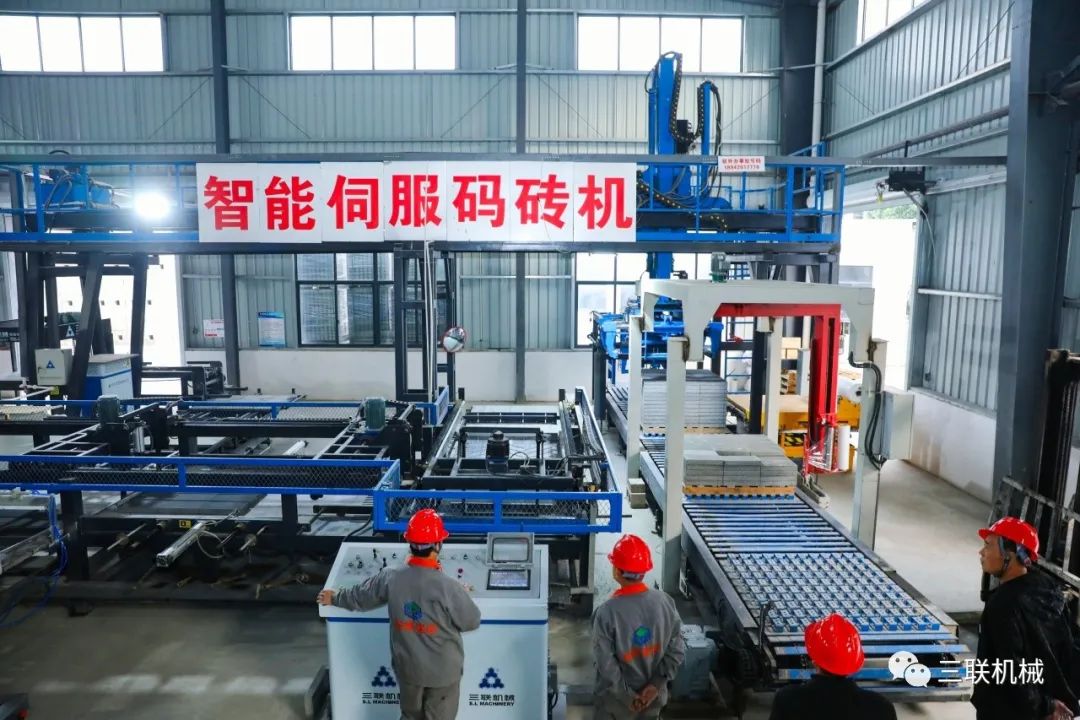

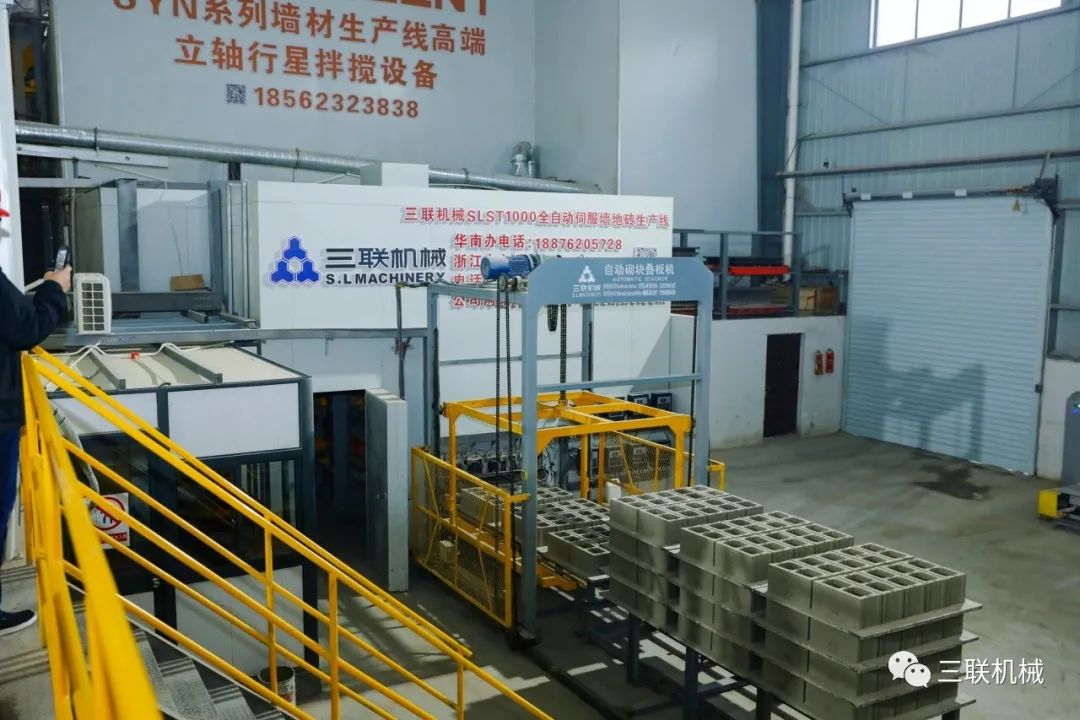

On the afternoon of the 15th,Delegates visited the production site of Sanlian Machinery's old customers.-Tonglu Qiangji New Building Materials Co Ltd。

On the afternoon of the 15th, the attending representatives visited Tonglu Qiangji New Building Materials Co., Ltd., a production site for old customers of Sanlian Machinery.

Tonglu Qiangji Building Materials Co., Ltd. introduces Sanlian MachinerySLSTModel 1000/SLSTModel 1500 dual-engine production line,Equipped with high-level brick receiving line and ferry curing kiln system。Enterprises save energy through intelligent manufacturing、Recycle and save water、Space development saves land、Turn waste into treasure and reduce carbon、Noise reduction with harmonious sound、Improve efficiency at the source,The annual water saving of the enterprise can reach more than 300,000 tons.,The whole production process realizes zero discharge of sewage.,The rate of land use has increased twofold.;Making all kinds of concrete bricks and craft bricks,All types of finished products processed including coarse aggregate、Fine aggregate、Powder,It can absorb more than 600000 tons of renewable raw materials every year.,The stone waste is recycled.、Decoration garbage、Construction waste and other solid wastes,It has created good ecological environment and economic benefits.。

Tonglu Qiangji Building Materials has introduced a dual machine production line of SLST1000/SLST1500 sanlian machinery, paired with a high-level brick collection line and a ferry maintenance kiln system. The enterprise has achieved an annual water saving of over 300000 tons through intelligent production, energy-saving, recycling and water conservation, space development and land conservation, transforming waste into treasure, reducing carbon emissions, reducing noise through harmony, and improving efficiency from the source. The entire production process has achieved zero sewage discharge, and the land use rate has doubled; Produce various types of concrete bricks and process bricks, and process various finished products including coarse aggregate, fine aggregate, and powder. Each year, a total of over 600000 tons of recycled raw materials can be consumed. Solid waste such as stone waste, decoration waste, and construction waste are recycled and utilized, creating good ecological and economic benefits.

Visit the site