2023 China(Foshan)During the International Exhibition of Hydrogen Energy and Fuel Cell Technology and Products,CumminsAcceleraSend the good news again,Its first domestic proton exchange membrane(PEM)Hydrogen production equipment in Cummins Enze(Guangdong)Hydrogen Energy Technology Co., Ltd. Foshan Base Begins Hydrogen Production Test,A sign that Cummins has“Preparation, storage and application”All-round localized green hydrogen industry chain capability,Customized service to customer needs,And lead the development of China's green hydrogen technology and industry。

▶Slide left to see more highlights

End of April 2023,Cummins Enzer's first localized productHyLYZER®-1000 in its FoshanPEMProduction base of electrolytic water hydrogen production equipment put into operation。After six months of intensive production,,The equipment starts hydrogen production test.,At the same time, it entered the stage of product prototype verification in the test room.,It will be delivered to the customer after completing the test and verification of the whole system.。

▶Slide left to see more highlights

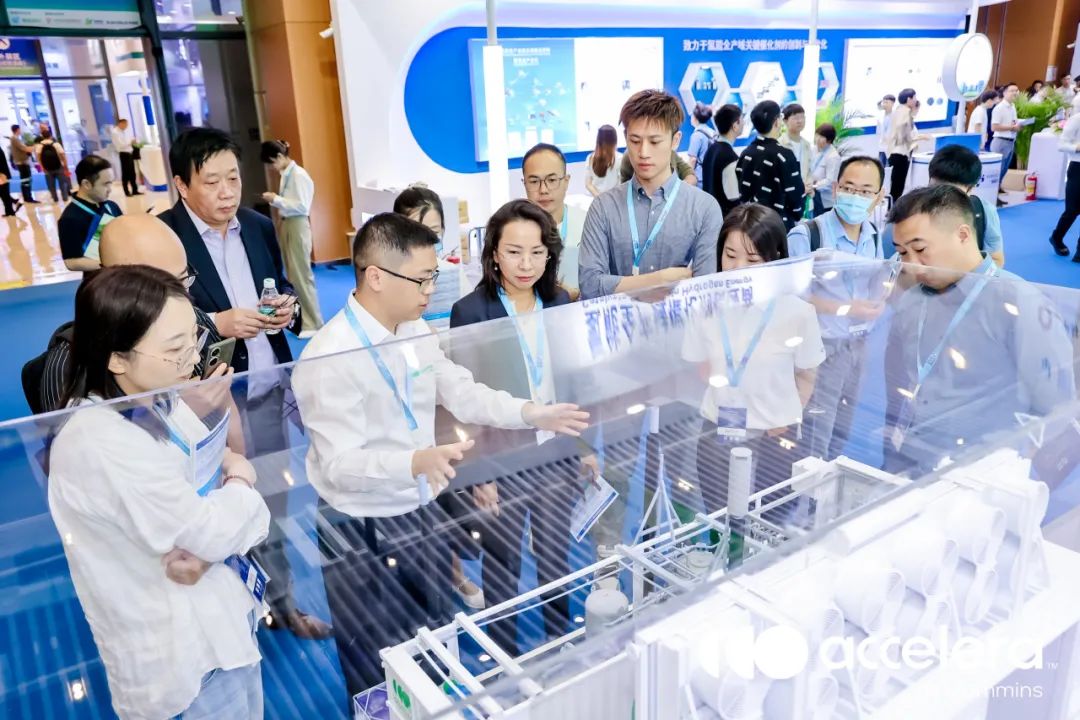

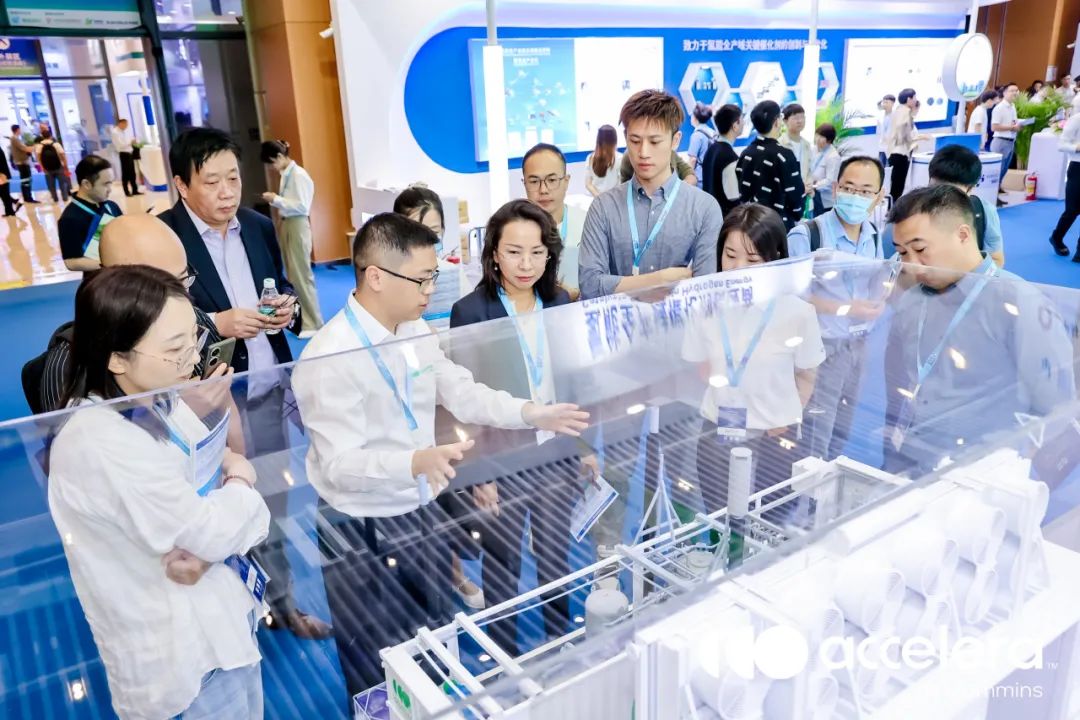

During the exhibition,Executive Vice President of China Center for International Economic Exchanges Zhang Xiaoqiang and his delegation visited Cummins Enze Green Hydrogen Equipment Manufacturing Plant,Witness the hydrogen production test of the first localized product,And in-depth exchanges on promoting the large-scale promotion of green hydrogen and the development of green hydrogen technology。

This product is based on Ultra100,000 hoursLocalized R & D and production based on European market verification,Skidded products for indoor arrangement,Hydrogen production capacity is1000 standard square meters/Hour (2160 kg/God),Mainly serve the factory、Centralized hydrogen production application scenario。

Vice President of Cummins,Sai Junfeng, Chief Technology Officer of Cummins China(Stephen Saxby)Share“Accelerating Energy Transformation with Innovation to Drive a Zero Carbon Future”

In addition to excellent technology and product introduction,The first batch of localized products rely on the advantages of Cummins' global supply chain and excellent operation system.,Minimize direct material costs,And product design、Overall manufacturing and service costs。Cummins Enze production base combines the non-standard customized production mode of chemical industry with the standardized scale production mode of automobile industry.,Form an innovative production model,While ensuring the quality of hydrogen production equipment,Dramatically reduce lead times。

In addition,While focusing on the localization of hydrogen production equipment, the localization engineering and technical team of international standards,And greatly promote that research and development of hydrogen production equipment.、Manufacture、Iteration of services,It not only improves the speed of product development and upgrading,,It also accelerates the production process of domestic hydrogen production equipment and the service optimization of the whole life chain.。At the same time,Back-office service system and support team,It ensures that the hydrogen production products are delivered.,Customers can always get a comprehensive、Reliable technical support throughout the life cycle,To provide users with more reliable protection。

Complete localized hydrogen energy solution

Continuously create value for users

This exhibition,CumminsAcceleraProducts on display also include high-power hydrogen fuel cells.HD240,This series of hydrogen fuel cells is characterized by its stability,、Durable performance has successfully driven the first batch of hydrogen fuel cell buses in Shanghai Lingang.、Green municipal projects such as hydrogen fuel cell muck Truck,The total mileage has exceeded 6 million kilometers.。

Among,The 100-km hydrogen consumption of Shanghai Lingang Hydrogen Fuel Bus Project during the operation period is4.86 kilos,Better than the industry level approx.8%,And help reduce carbon dioxide emissions.170 tons,Nitrogen oxides are reduced2.86 tons,Solid particle emission reduction6.76 tons。

Cummins' layout in the field of electric powertrain also covers high-performance electric drive systems.,Includes safe and efficient motor platform,Over 85%The proportion of efficiency area can reach88%~90%,Lower overall operating cost,At the same time, the modular system design and stable torque control can be continuously extended and expanded according to the high quality requirements.,And precise control to improve passenger ride comfort;And specially designed for China、Highly integrated and versatile electronic control system for heavy-duty Vehicle design,Reliable combination of hardware and rich software capabilities。

In June this year,Issued and implemented by China《Compressed hydrogen plastic liner carbon fiber full winding gas cylinder for Vehicles》National Standards,Further manufacturing of type IV hydrogen cylinder、Transportation、Safety technical requirements are put forward in use and other aspects.。Cummins has over 40 years of experience in filament winding technology,The product covers the Vehicle、Various applications such as transportation and in-station hydrogen storage。Cummins will leverage industry-leading technology development capabilities and manufacturing experience,To provide Chinese users with high reliability that meets the requirements of Chinese regulations、High-pressure hydrogen storage products and system solutions with high hydrogen storage density and long service life。

With the first localizationPEMWater electrolysis hydrogen production equipment starts hydrogen production test,CumminsAcceleraComplete localized hydrogen energy solutions are available,Overlay made from green hydrogen、Storage to Zero Carbon Powertrain Solutions,Will continue technological innovation、Localized scale production capacity、Customized service system,Help local users achieve carbon reduction targets。