Deji Machinery: Follow the Trend and Face the Difficulties

October 25, 2023

At present,The highway undertaking of our country is in the stage of maintenance.,Every year, a large number of waste asphalt mixtures are produced due to road maintenance and repair.,The recycling technology of Asphalt Mixing Plant came into being under this background.。

Actually, back in 2003,,Deji Machinery took the lead in developing and introducing double-drum regeneration mixing equipment.,It leads and promotes the technological progress and technological innovation of asphalt mixing equipment.。In 2014, it also launched the integrated plant mixing hot regeneration mixing equipment initiated by Deji Machinery and obtained patents.(Patent No:ZL 2014 2 0075123.7)。

Deji Machinery Integral Plant Mixing Hot Regeneration Series Equipment

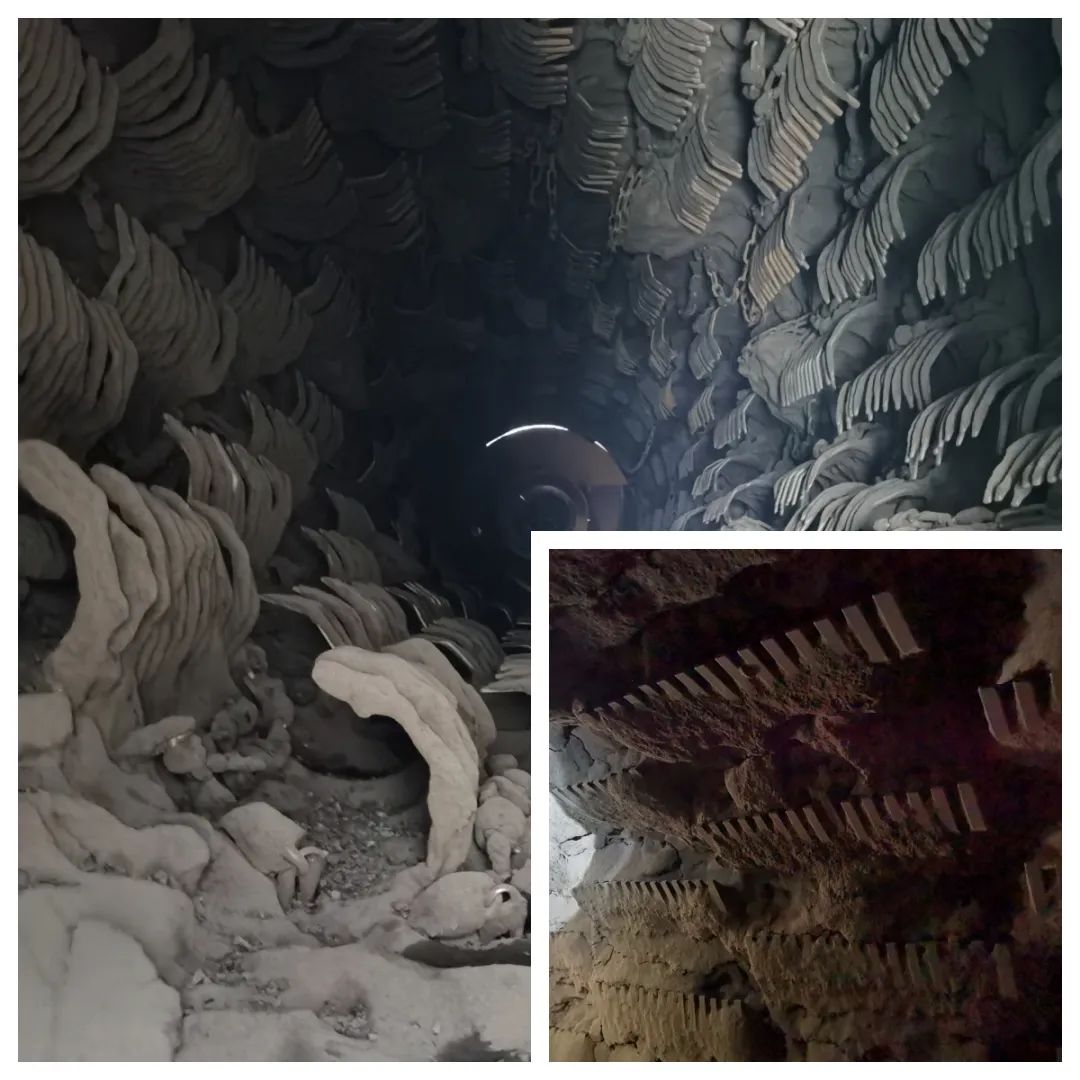

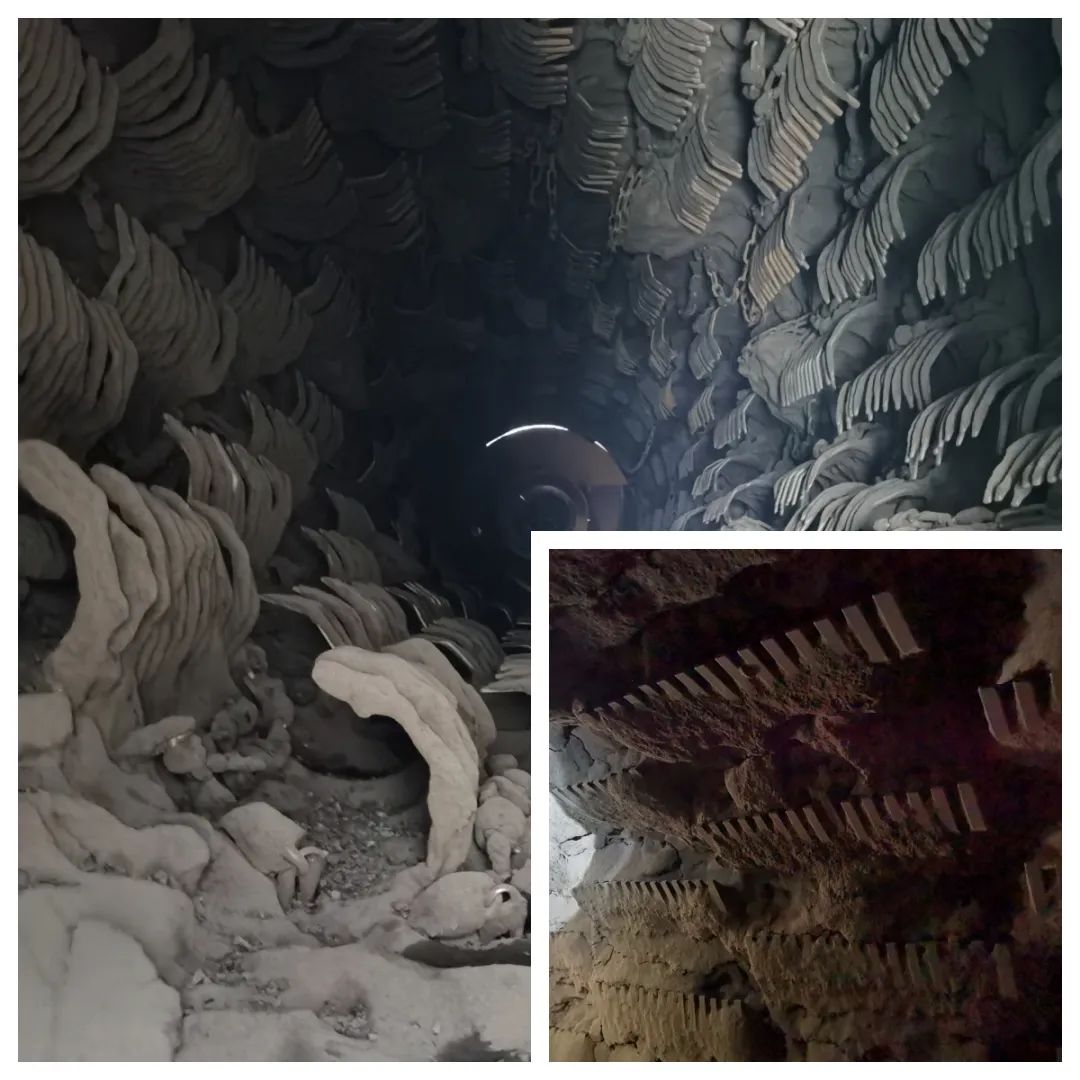

In recent years,With the extensive application of recycling technology of Asphalt Mixing Plant,,We found that the hot regeneration drying drum in the current industry generally has the problem that the internal regeneration material sticks to the blade in a short time.,So that the weight of our drying drum will continue to increase with production time.,This undoubtedly increases the operating load of the equipment.,And that internal bind has to be cleaned periodically.,At the same time, it brings many problems, such as the reduction of equipment production efficiency and the increase of cleaning costs.。

The recycled material inside the hot regeneration drying drum is seriously bonded in a short time.

In response to this phenomenon,Deji Machinery has developed and launched a new generation of downstream self-cleaning drying drum.,And obtain a patent(Patent No:ZL 2023 2 1077475.1),Not only in the structure of the design innovation.,It's also increased“Self-cleaning”Module design,So that that equipment can be operate in the process of production“Self-cleaning”,Extend the cleaning cycle of the drum 3-5x,Reatly reducing the cost investment of cleaning the roller,The production efficiency of the equipment is improved.。And,The structure of the new generation of downstream self-cleaning drying drum is more conducive to the formation of a uniform material curtain.,So that that regenerate material is heated more uniformly,Improve the overall thermal efficiency of the drum,Olves the problem that the tail gas temperature of the traditional sliding type roller is too high.,The off-gas temperature can be controlled to be only 10% higher than the discharge temperatures℃Left and right。

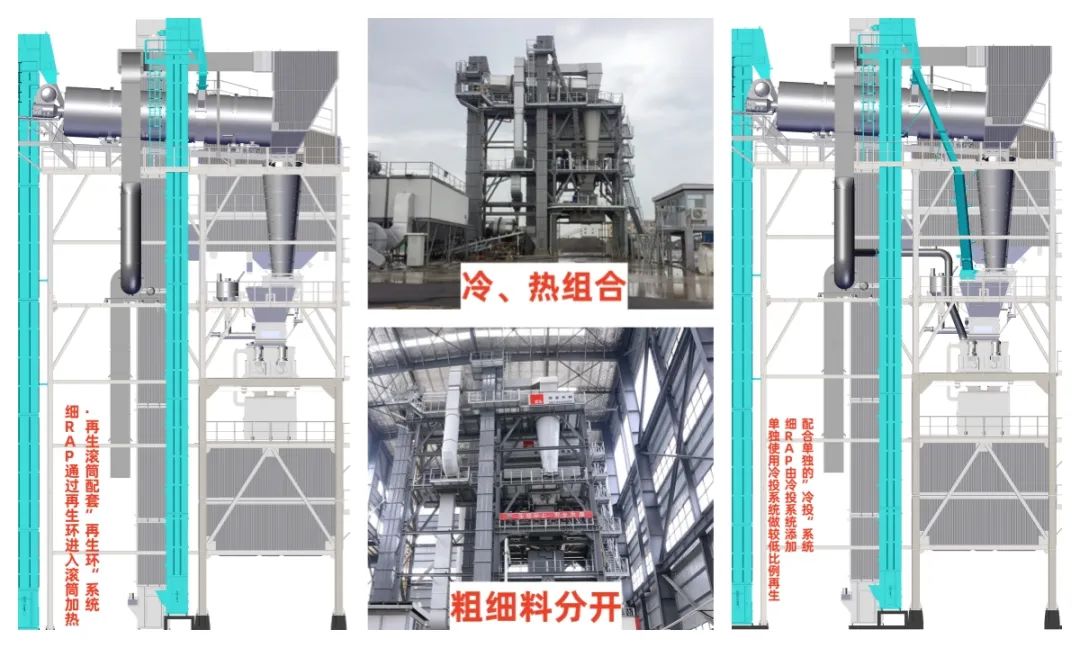

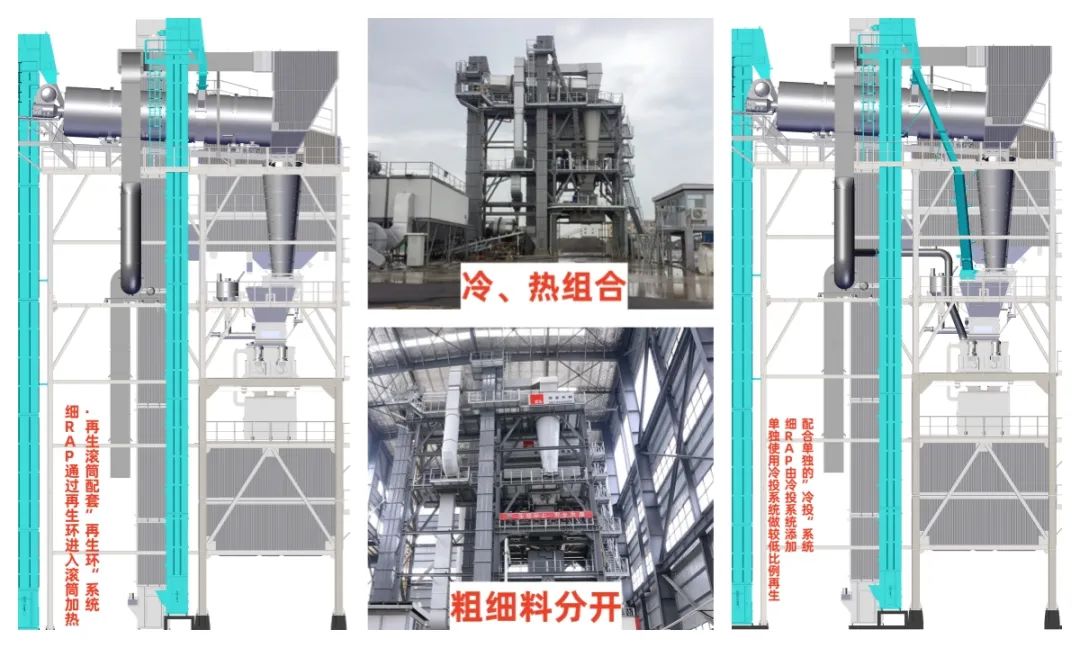

Multiple regenerationXCombination mode

Multiple regenerationXCombination mode

Compare with that design of a reverse-flow drying roll in the industry at present,,The downstream drying drum has the following advantages:

1、The dedusting flue port is arranged at the discharge end of the roller,Regenerated fine material feed is not easily pumped away by the air duct;2、Simpler control system,Convenient and easy to operate;3、Removed the counterflow type furnace and the cold air reflux cooling device of the whole set of furnace,It saves a lot of cost investment in later maintenance.;4、The overall cost of equipment and the cost of later maintenance are lower.;

Deji Machinery has been focusing on the R & D, design and manufacture of mixing equipment for recycling waste asphalt mixture.,In addition to the traditional plant-mix hot recycling technology,Continuous cold plant-mix recycling equipment can also be provided.、Regeneration additive system and other regeneration technologies,It is also suitable for the equipment transformation of most brands and models at present.,Provide a total solution。

Multiple regenerationXCombination mode

Multiple regenerationXCombination mode