Is the Asphalt Mixing Plant you bought a big and useless energy consumer?,Or is it up to you to act like an arm?“An alchemist”,Depends on the technical content hidden in the hard body of steel.。

Burner、Drying drum、Mixing cylinder、Dust remover、Control system and other core components,Related to the production efficiency of Asphalt Mixing Plant、Discharge quality、Reliability and service life,Therefore, it can best reflect the real strength of the equipment.。

Anmai has a highly efficient mixing technology that has been patented worldwide、Reasonable matching technology of the whole machine、Leading energy-saving technology、Superior recycling technology with a high percentage of recycled materials and intelligentas1 Control system;He also has more than 100 years of experience in asphalt mixing equipment production.,It guides us to constantly evaluate.、Optimize design and manufacturing processes,Create additional revenue for customers。

Nowadays,Environmental performance is becoming more and more important in the competition of different brands of Asphalt Mixing Plants.。Anmai will not only consider safety in the process of product development.、Efficiency、Productivity and maintenance costs,And we are constantly exploring all possible ways to reduce the carbon footprint of our products.。

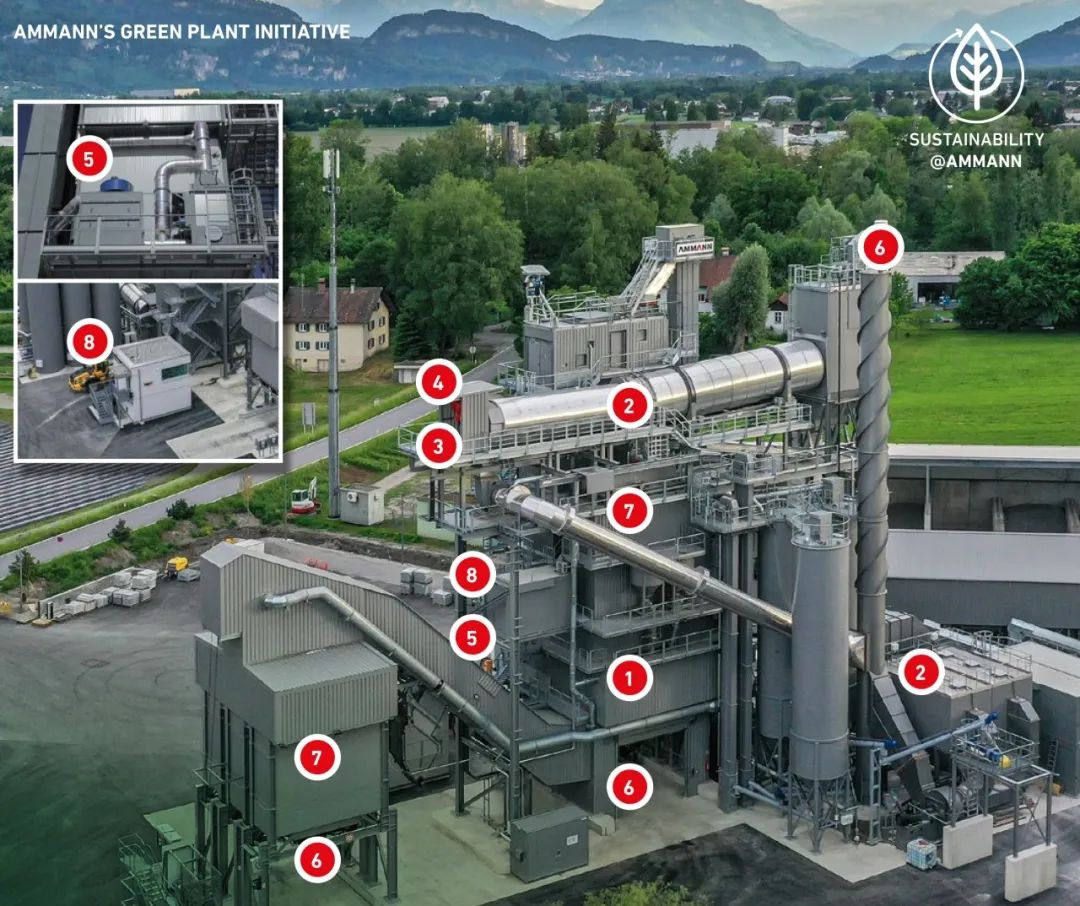

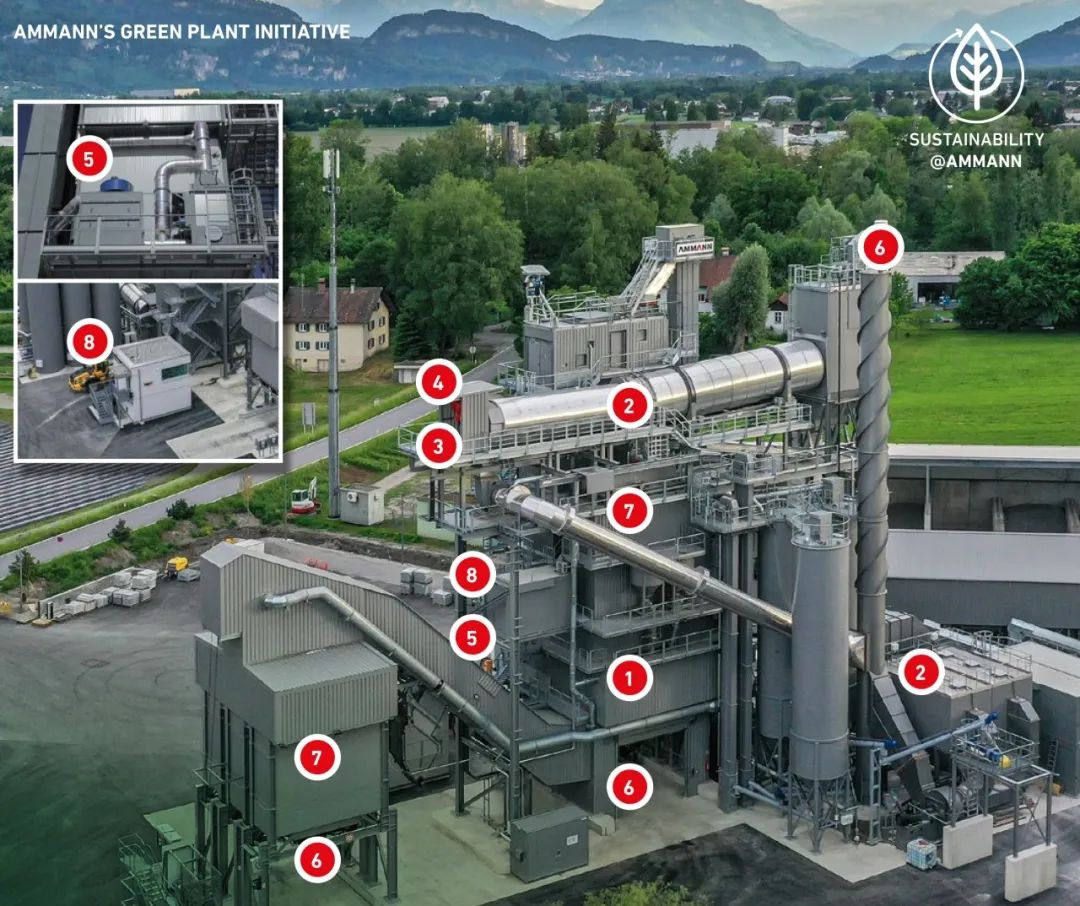

During the production of asphalt mixture,Possible contamination from each step——Mainly dust、Noise、Asphalt fumes and odors,Countermeasures can be found in the environmental protection solutions of Anmai Mixing Station.。These forward-looking“Green mixing station initiative”(Green Plant Initiative),It represents Anmai's spirit of independent innovation for more than a century.,And the determination to resolutely promote sustainable development.。

There is no detailed analysis of all the measures of Anmai Green Mixing Station below.,Only a few of these items are listed in the order in which they are labeled in the figure.。

01

Asphalt foam process base on Anmai(Ammann Foam)Warm mix asphalt technology。Reducing production temperature can reduce energy consumption and emissions.,It is an environmental protection practice recommended by Amay.。

02

Heating process。Including efficient heat transfer,And optimized Burner、Drying drum adjustment。This is the key link to reduce production costs.。

03

Burner。Anmai Burner is suitable for all kinds of liquid、Gas and solid fuels,Low fuel consumption and low emissions through efficient combustion。A New Type of Burner for Carbon Neutralization,It is being used in more and more Anmai Asphalt Mixing Plants.。

04

RecyclingRAPMaterial。Anmai provides ring regeneration、The second drum is regenerated、High proportion of regeneration and many other cold、Thermal Regeneration Solution,Help customers achieveRAPAdd scale from 15%To 100%Application of。

05

Blue smoke treatment(BST)。BSTReduce bitumen fumes by capturing and filtering vapors emitted during loading,Improve air quality。

06

Emission reduction。Reduction of carbon dioxide in asphalt production、Volatile organic compounds and nitrogen oxides;Energy saving and emission reduction with the help of drum active cooling technology and enhanced drying process,Reduced impact on the environment。

07

Avoid heat loss。All AMAI Asphalt Mixing Plants and components are optimized for high energy efficiency and low heat loss——Include thickened insulation,Non-thermal bridge design and waste reduction。

08

as1 Control system。A new generation of user interfaces makes Anmaias1Control system becomes more intuitive、Easy to use,Help users be efficient、Accurately control and monitor the operation of Asphalt Mixing Plant。Advanced users can also choose various additional functional modules to upgrade the software according to their own needs.。