”

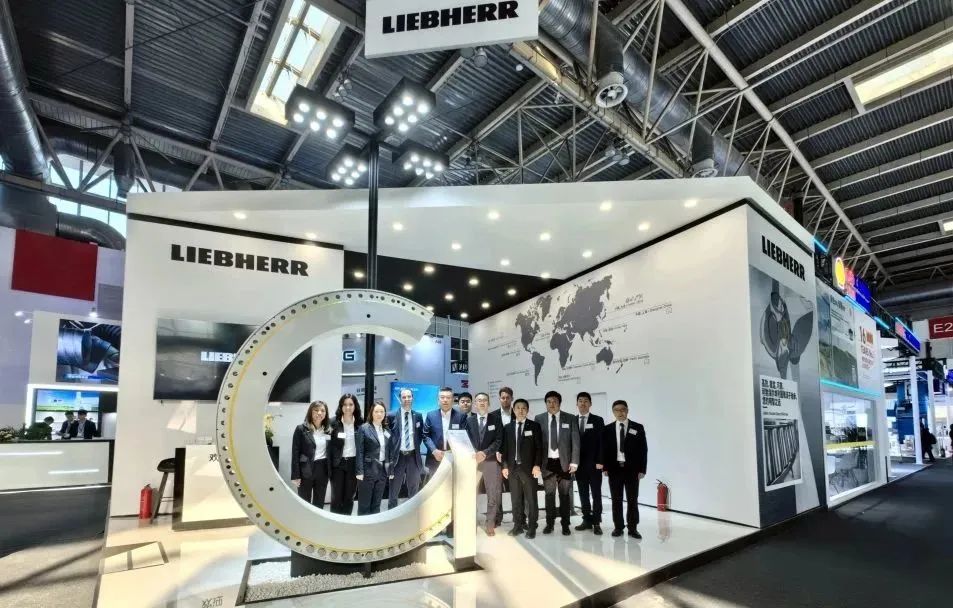

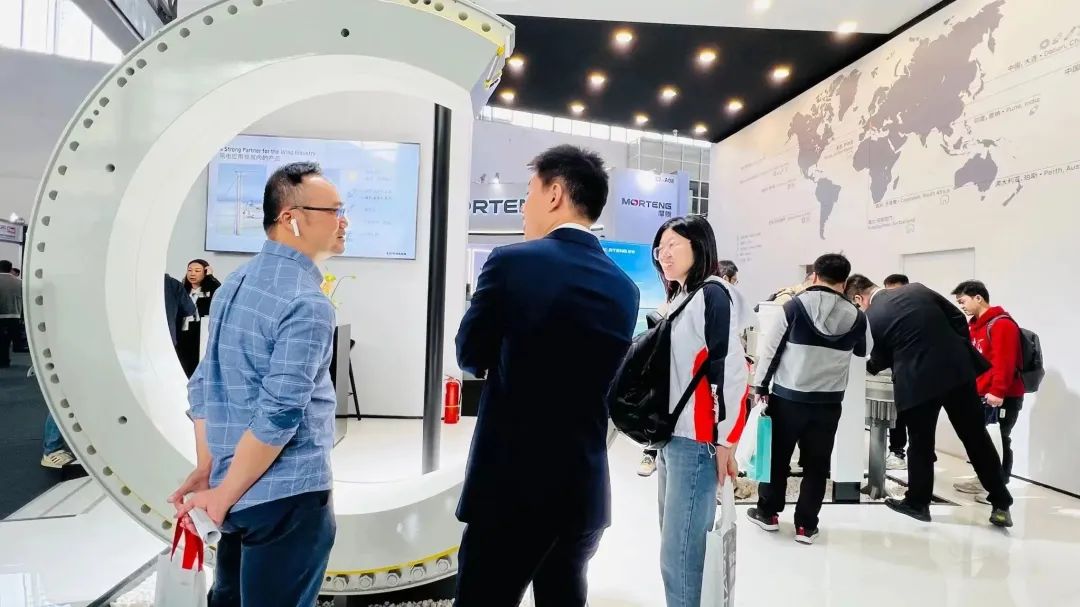

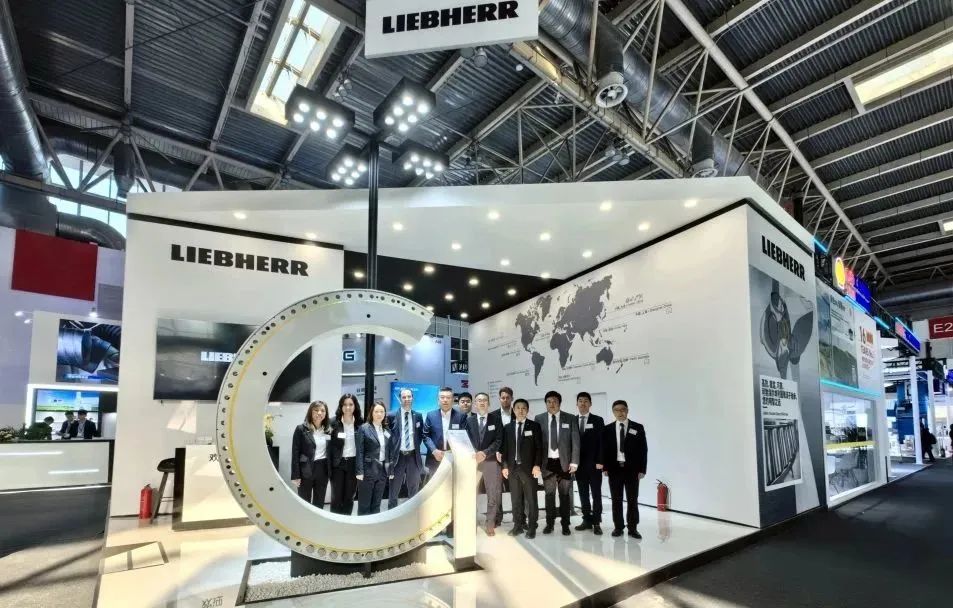

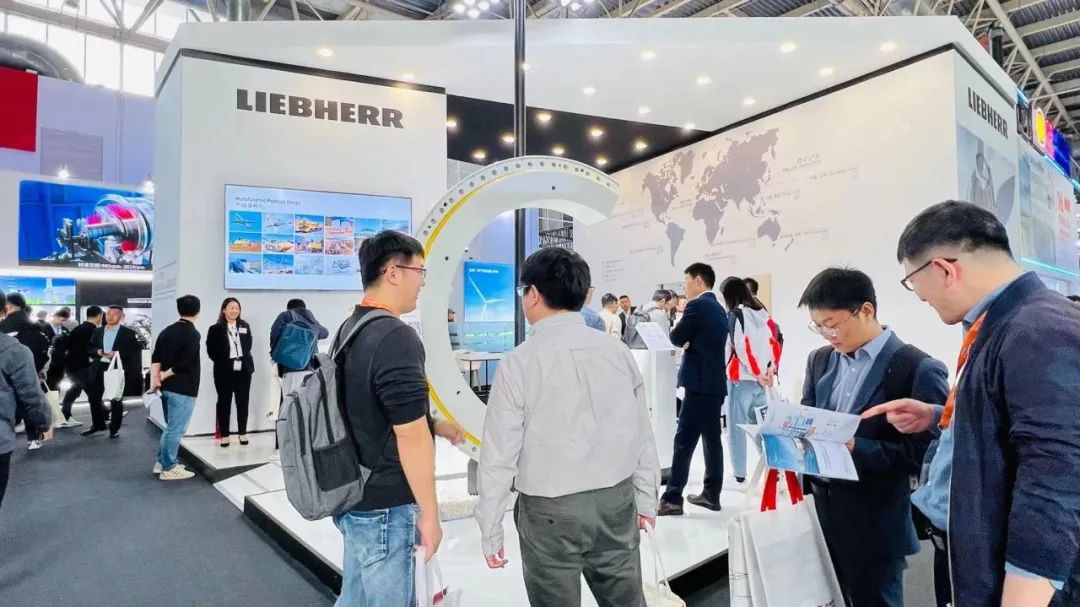

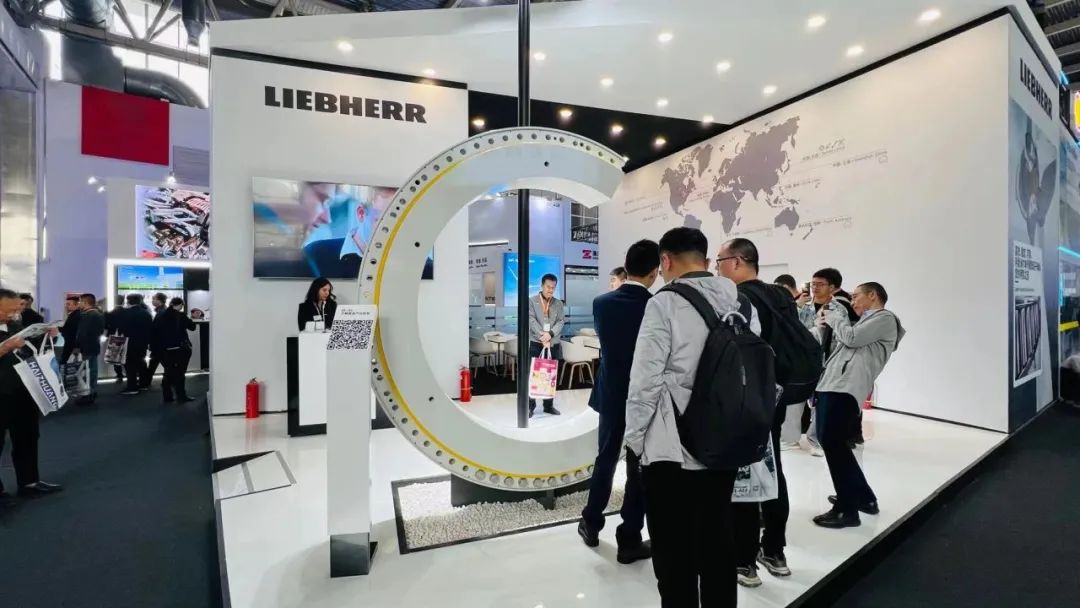

October seventeenth,Beijing International Wind Energy Conference was officially held in 2023。Liebherr is thinking about the future energy development pattern.,Solutions designed and developed for China's wind energy market were presented at this exhibition.。

Liebherr as a strong partner in the wind industry,Continuous innovation and emphasis on green and sustainable development are the foundation of Liebherr's life.。It has entered the Chinese market for more than 40 years,Deep understanding of China's green development、Carbon neutrality essentials,And the deep significance of intelligent manufacturing.。We continue to actively explore,Seek win-win cooperation for long-term green and sustainable development。

Wind power main bearing:

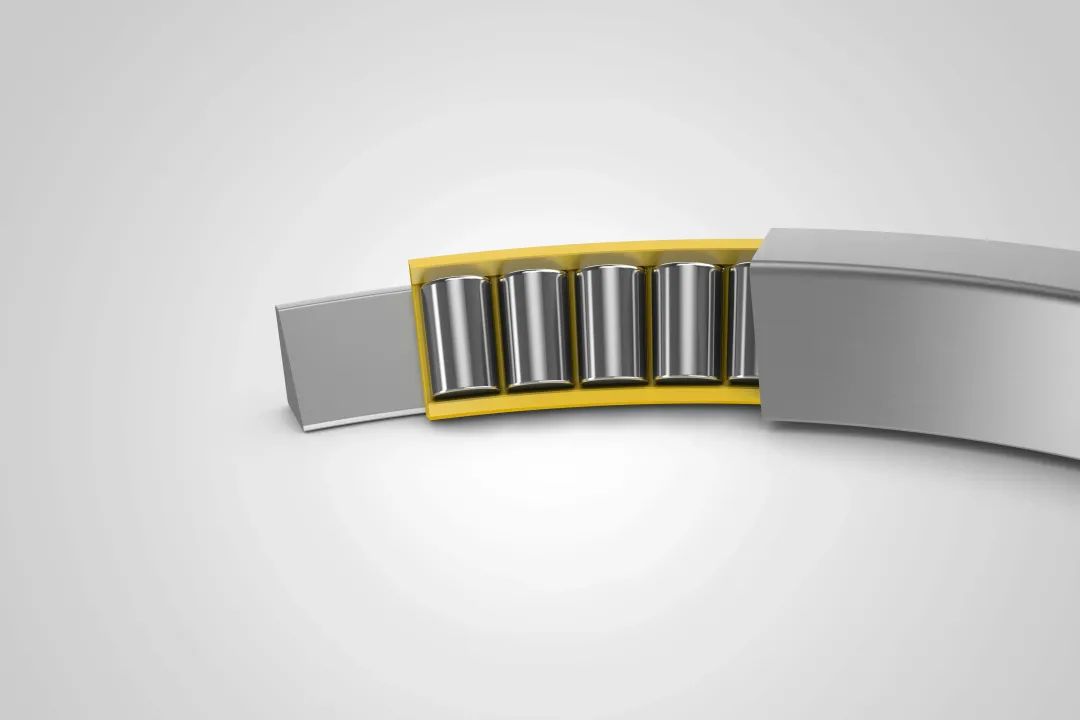

Single-row tapered roller bearings

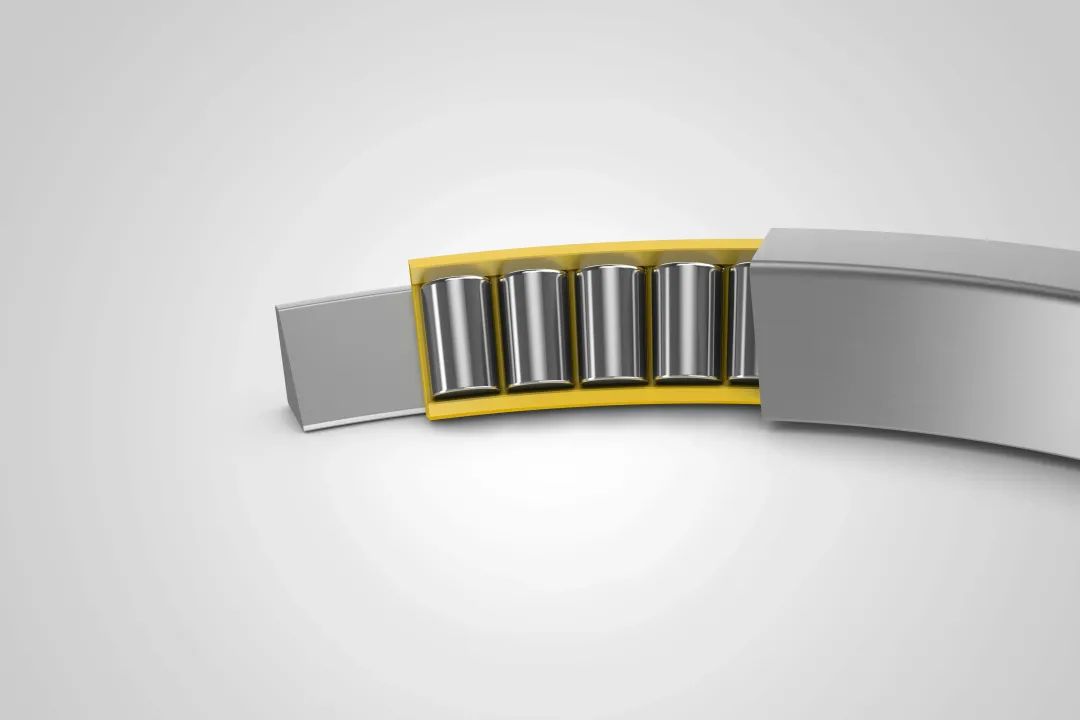

Divide into two:The configuration scheme of two single-row tapered roller bearings has gradually become the mainstream trend in the design of Wind Turbine main bearings.。They are mounted on the shaft at a distance apart.,This reduces the moment effect。In design,Opposed double row tapered roller bearings,They have also been drastically reduced in size.。

Single row tapered roller bearings as main bearings for Wind Turbines。

Liebherr has now developed and mass-produced a main bearing configuration consisting of two single-row tapered roller bearings。In order to ensure the correct design of the bearing preload,Liebherr is precisely defined during the development process by means of a complete finite element calculation.,The optimized bearing layout and design ensure optimum rolling characteristics and ideal load distribution。By means of precision rollers combined with narrow manufacturing tolerances,Precise preload is ensured after correct installation,Achieve ideal load distribution。In addition,The Liebherr main bearing test bench has been validated by functional tests and life tests of single-row tapered roller bearings。

So how to build this high-precision bearing to meet the efficient operation of wind power??

High complexity in production:

Induction hardening process and superfinishing

“Setting bearing rings during seamless quenching has been a challenge,”Head of Technical Sales, Bearings Business Unit, Liebherr, Biberach, GermanyStefan MilotzkeExplained。“The experience we have gained over the years has enabled us to perform a perfectly coordinated operation of the four inductive heads.。This is particularly important.,Because it allows us to meet the high requirements for hardening depth and surface hardness.,”MilotzkeExpress。Superfinishing further completes the raceway surfaces:In the process,Optimization of the raceway surface improves the wear resistance of the bearings、Anti-friction and improve lubrication condition。This ensures extremely high raceway surface quality and longer bearing life。

Two single-row tapered roller bearings are used as the main bearings of the Wind Turbine.

Bearing technology:

Inheritance and innovation

The main bearing in a Wind Turbine must withstand a constantly changing load,And operate in harsh conditions.。In offshore wind power applications,These bearings are even more frequently exposed to corrosion and salt spray.。With the development trend of large-scale Wind Turbine,Bearing sizes are also becoming larger.。

Based on nearly 30 years of experience in the wind industry,Liebherr's technology and products meet these application requirements,Three-row roller bearings are available for various types of products and environmental applications.、Double row tapered roller bearings to the present single row tapered roller bearings and other main bearing products。Onshore and offshore customers also include leading national and international Wind Turbine manufacturers,At present, the power of Wind Turbines on the cooperative project is as high as 14 MW.。

Quality reaches the highest standard in the industry——

LiebherrAPQP4WindMembership

Since 2022,Liebherr Components has always beenAPQP4WindA member of。APQP4WindAs an industry standard,Adapt systems and processes to the requirements of the wind industry,And improve the effectiveness and efficiency of component qualification and delivery for the wind industry。We are honored to beAPQP4WindA member of!

Designed for Chinese customers

——Dalian New Parts Factory

For more than 70 years,Liebherr has always represented the leading complex products.、Growing innovation and focus on quality。Early 2023,It opened a new factory in Dalian, China.。This adds to the strength of Liebherr's component products division.,And has further expanded its global operations.。It has more than 250 employees.,Main bearings for the wind industry、Variable pitch/Yaw bearing and swing drive。The new plant in Dalian will become one of Liebherr's central production bases for components.,It will further strengthen Liebherr's international footprint in the wind power market.。

Liebherr Parts Plant in Dalian, China