Hefei is located in East China.,It is a sub-central city of China's Yangtze River Delta urban agglomeration approved by the State Council.,Yeah, too“The Belt and Road”An important node city。Hefei Xinqiao International Airport is an important part of the world-class airport group in the Yangtze River Delta.,In order to meet the rapid growth of aviation business,,Hefei Airport Phase II Reconstruction and Expansion Project officially started construction on November 15, 2021.。The total investment of the project is about 25 billion yuan.,The implementation of the reconstruction and expansion project mainly includes the expansion project of the terminal area and the expansion project of the flight area and working area.,It is planned to be 2025,Hefei Xinqiao International Airport Phase II Reconstruction and Expansion Project Completed,It will help the Yangtze River Delta build a world-class airport cluster.。

Hefei Xinqiao International Airport Phase II Effect Display

During the construction of Hefei Xinqiao International Airport Phase II Flight Area,In order to better meet the construction accuracy and construction period requirements of the earthwork layer, the earthwork construction unit responsible for the second bid section,Topcon 3 introduced separatelyD-MC2 Motor Grader Control System and TopconX53x 3DExcavator control system,Combined with the earthwork layered construction design data provided by the design unit,It provides solid technical support for the precise filling of earthwork layer by layer.,The construction efficiency and schedule have been significantly improved.,And the measurement of the precise leveling link is greatly reduced.、Setting-out workload and personnel input, etc.。

Topcon 3DMotor Grader control system in the construction site of Hefei Xinqiao Airport earthwork precision leveling

Topcon 3DMotor Grader control system

Topcon 3DMotor Grader control system is to install various sensors on the motor Grader.,Realize the automatic monitoring and control of the shovel posture。Provide digital and graphic instructions to the driver during field construction,The system can directly control the automatic lifting of the Grader blade.,The work can be completed with high quality without stakes.,Reduce the work intensity and operation difficulty of the driver,While improving the quality of operation,Significantly improve work efficiency,The operation cost is greatly reduced。

Tuopukang 3 in this projectDThe Grader control system is mainly used for earthwork precision leveling operation.,In addition, according to the ups and downs of the original terrain,,Establish and scrape out the boundary line between different layers of earthwork,Make steps,Provide accurate boundary basis for subsequent filling layer by layer。

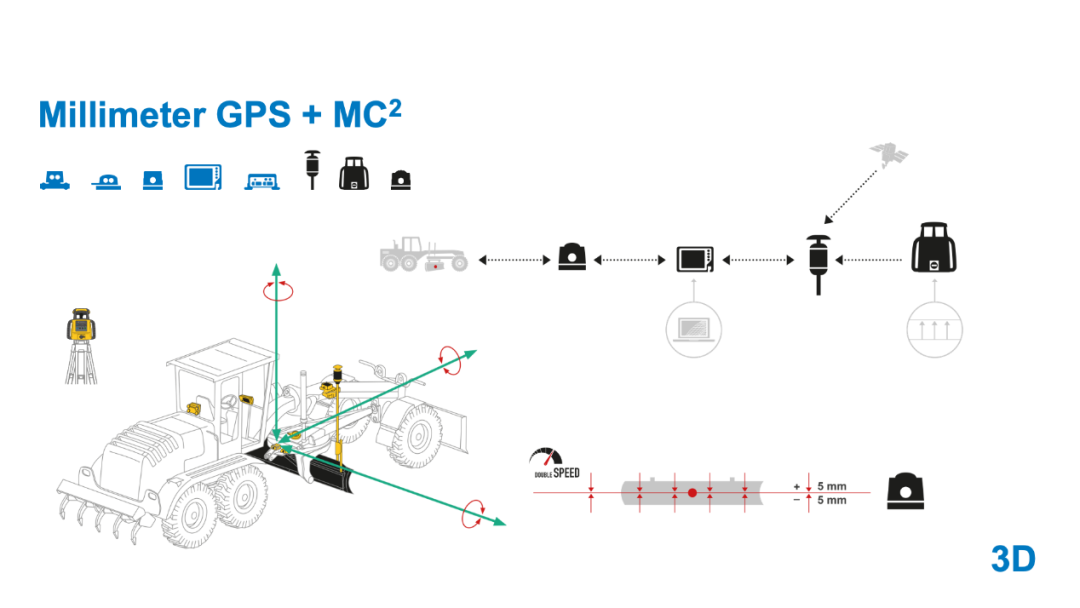

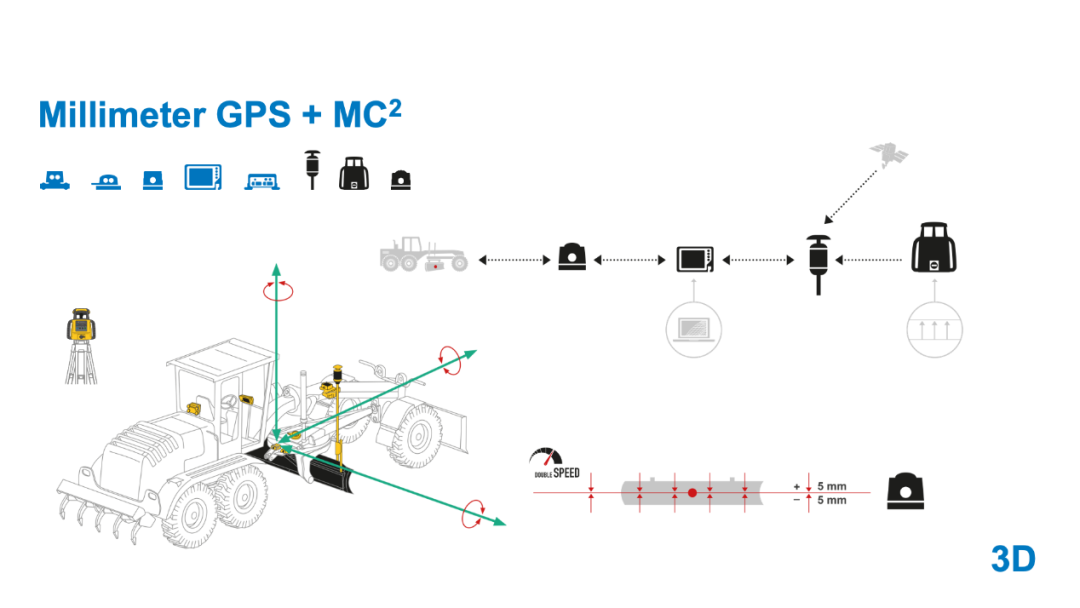

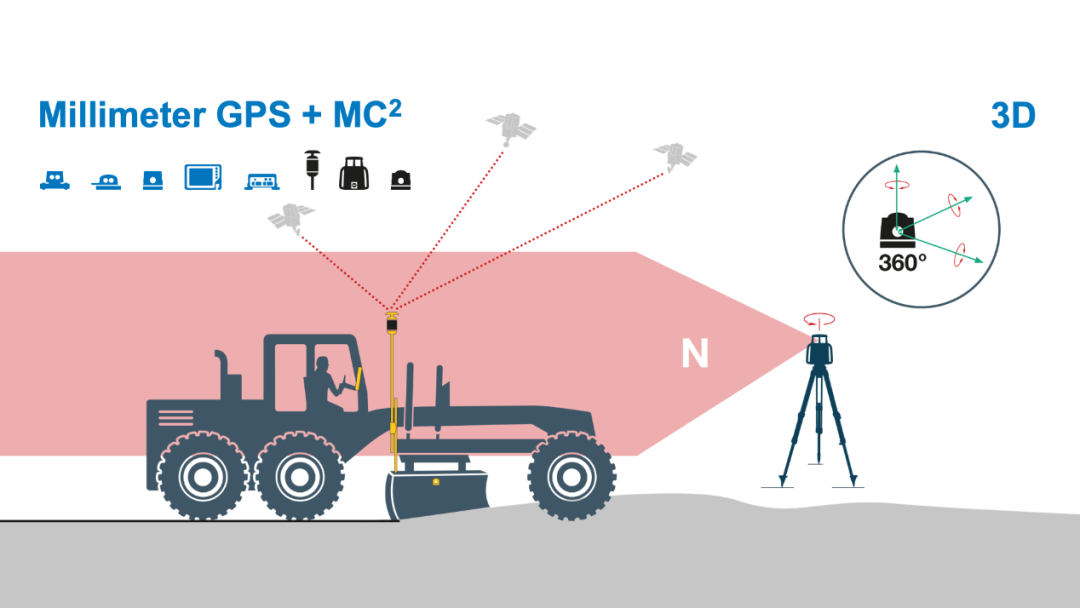

Topcon 3DMotor Grader control system(mmGPSEdition)Schematic diagram of composition

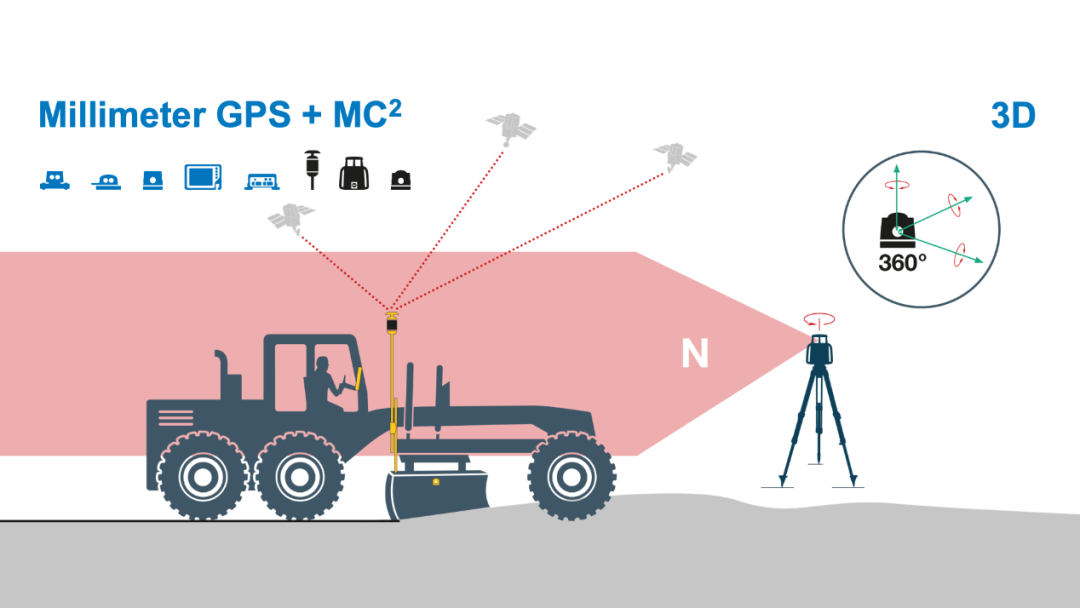

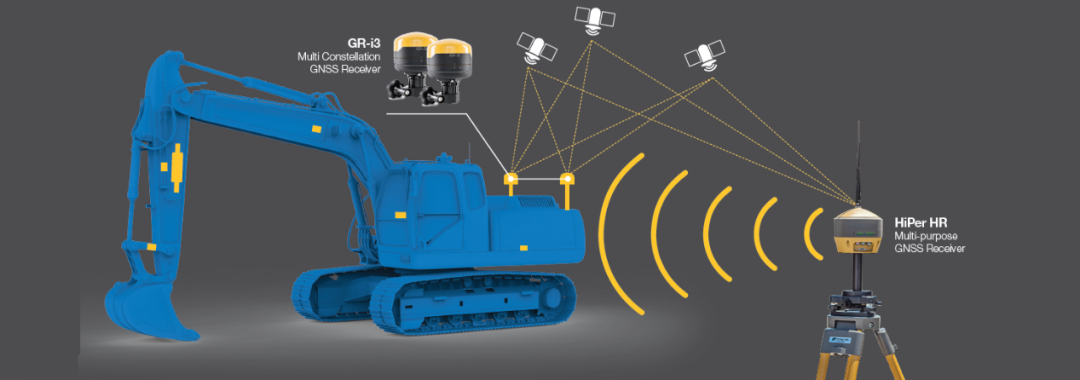

Topcon 3DWhen the motor Grader control system is operating,Erect outside the work areaGNSSReference Station,Provide reference differential data for on-board system。The Grader body is provided with a longitudinal slope sensor.(Used to determine the longitudinal slope inclination angle along the Vehicle body direction),Rotation sensor(Used to determine the blade rotation angle),Tilt sensor(Calculating Blade Lateral Tilt),And Topcon's uniqueMC² IMUSensor(100HzThe update rate obtains the angle and acceleration of the three axes of the blade in real time.),Obtained in combinationRTKThe positioning data can be used to calculate the posture and position of the blade.,Through the control box 3D-MCThe software calculates the deviation of the blade position from the pre-imported design data,Presented on the display in the form of numbers and graphs,At the same time, the control box converts the correction signal into an electrical signal,Transfer to hydraulic control system,Achieve automatic adjustment of the blade height of the Grader,So that the precision leveling operation can achieve the expected effect of the design.。

Topcon 3DMotor Grader control system(mmGPSEdition)Schematic diagram of working principle

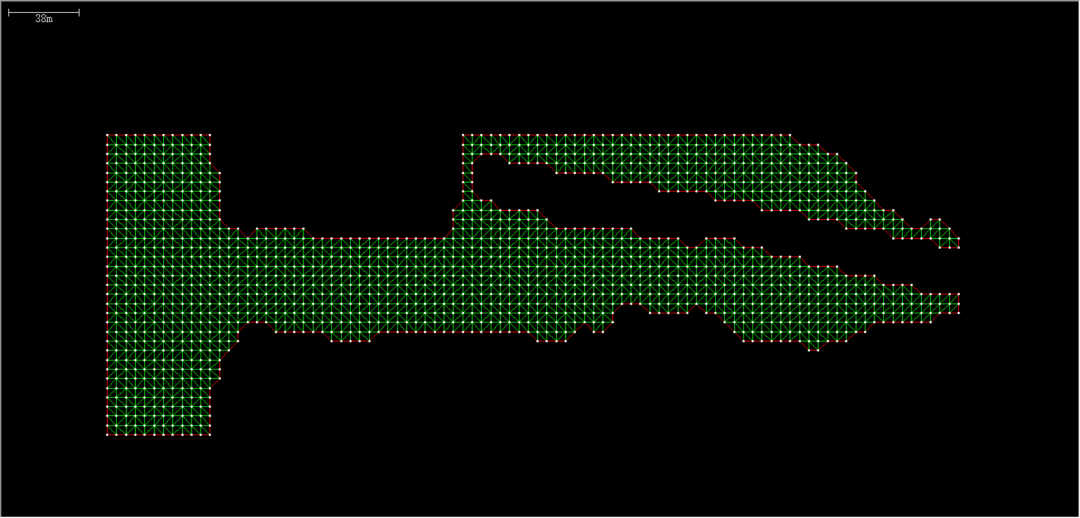

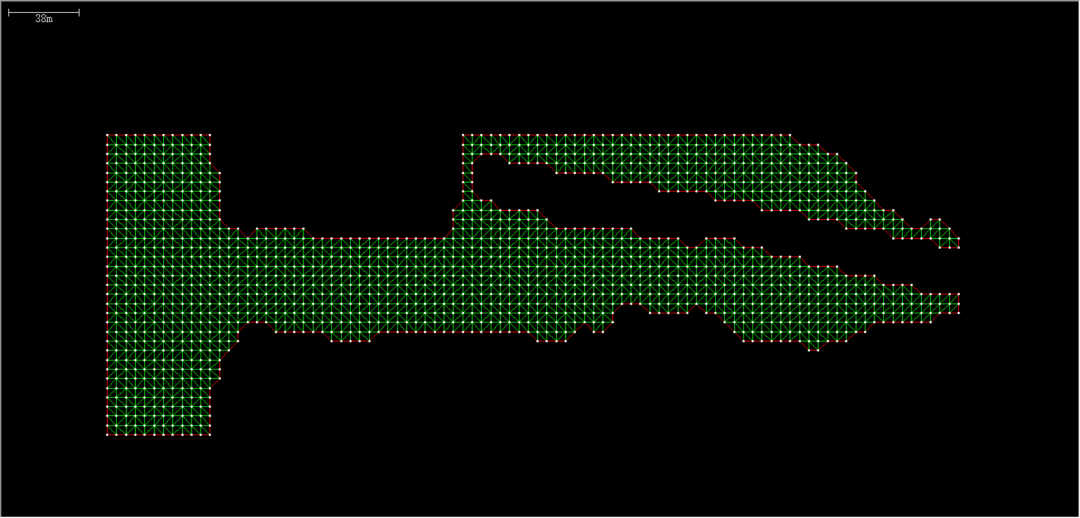

Determine the design surface of each layer according to the undulation of the original surface.(The picture shows 13 layers of earthwork 3.DDesign of digital modeling part)

Bench establishment and surface close between multiple layers of earthwork

Topcon 3DConstruction drawing for precise leveling of Grader control system

3DPrecision cross-validation check of earthwork precision leveling operation

Topcon 3DThe application of Grader control system in this project has completely changed the traditional fine leveling construction process.,Traditional finishing operations usually require scraping4~Six times,Topcon 3DMotor Grader control systemTwiceJust do itFinish the fine leveling operation,At the same timeReduction of manual pile placement inspectionInput,Reduce personnel involvement,Save time,Shorten the construction period。The system is based on three-dimensional design data.,Automatic control of the blade,And that skill requirement and the labor intensity of operators are reduce.,Reduce human error,Ffectively improve the operation accuracy。One-time construction to the design slope,Dramatically reduce repetitive tasks,Significantly reduce fuel costs and mechanical wear,Reduce cost and increase efficiency。Combined with the use of the project,Summary Topcon 3DThe Motor Grader Control System has the following advantages:

1

Innovative construction technology,Complex terrain can also be easily dealt with,The leveling of the multi-directional inclined slope can be completed;

2

Industry-exclusive 100HzInertial navigation module,Significantly improve construction efficiency,Reduce comprehensive construction costs such as fuel consumption;

3

Based onmmGPSHigh precision positioning system,Precision leveling typical elevation accuracy up to 5mm;

4

Based on 3DDigital construction design namelyBIMModel control leveling construction operation,Intuitive and convenient;

5

Topcon has a variety of motor grader configurations to choose from,Meet all kinds of construction needs。

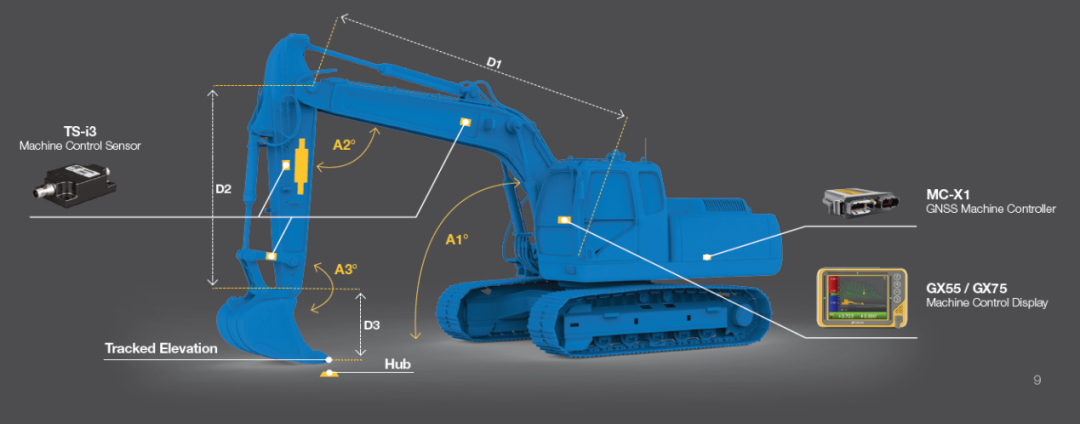

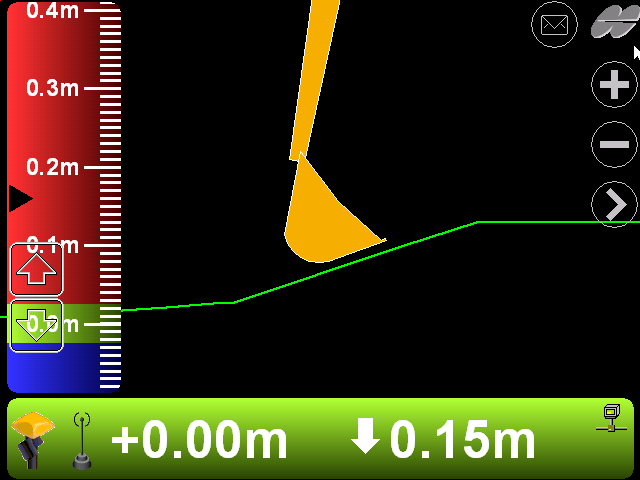

Topcon 3 is also used in this projectDThe Excavator system isX53xCarry out construction operation systematically,It is mainly used for step excavation and slope repair in earthwork construction.、Excavation elevation during ditch excavation and earthwork transfer(Depth)References, etc。

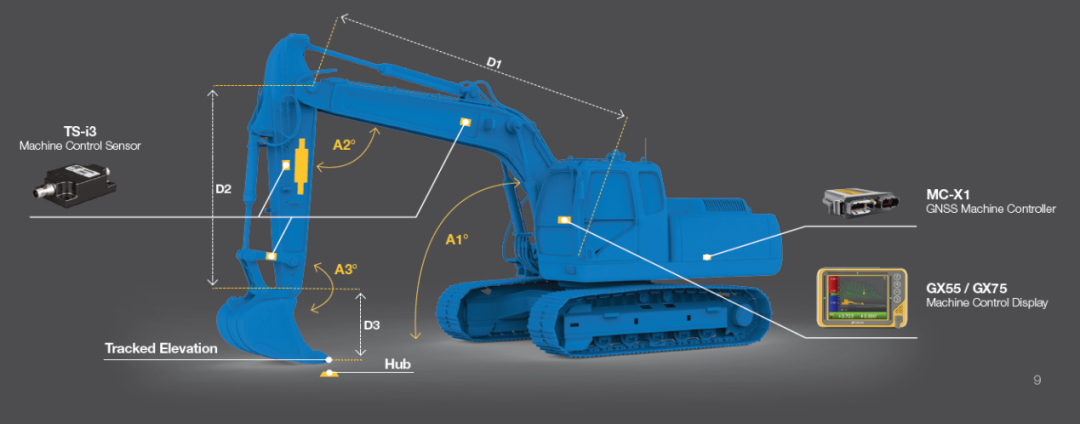

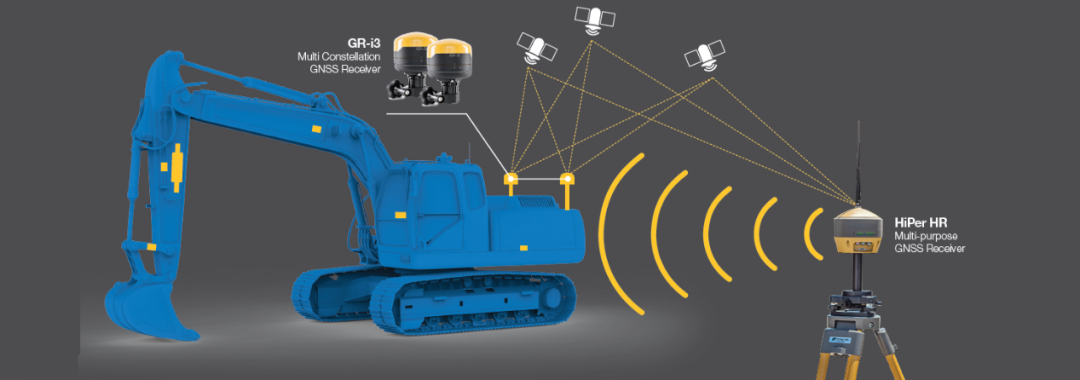

TopconX53x 3DExcavator system,Support the whole world including China's BeidouGNSSSatellite Positioning System,It's modernGNSSPerfect Embodiment of Precision Positioning Technology Combined with Precision Sensor Technology in Excavator Construction Application。The system is based on precision sensors and real-time、Quickly obtaining the operation attitude information of the Excavator,Make use ofGNSSPositioning technology calls precise location information in real time and combines it with construction design data.,O as to guide the operator to carry out precise operation.,The situation that the operation is carried out by guessing in the traditional construction is avoided.,Realize the new Excavator operation mode in one step。

TopconX53x 3DComposition of Excavator system

TopconX53x 3DSchematic diagram of working principle of Excavator system

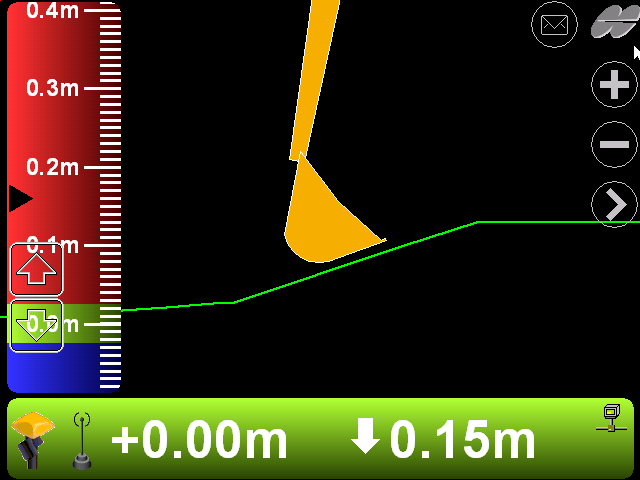

TopconX53x 3DExcavator system 3D-MCSoftware operation interface

TopconX53x 3DApplication Site of Excavator System in Xinqiao Airport 1

TopconX53x 3DApplication of Excavator System in Xinqiao Airport

The use of the Excavator guidance system at Xinqiao Airport,Help the operator to know the working height of the bucket teeth in the cab,It eliminates the need for repeated measurement and communication confirmation in traditional construction.,The whole Excavator system is a construction system.,Detection system again.,The operator can complete the operation of cutting the slope of the site with the least possible excavation.。Combined with the land leveling of Xinqiao AirportTopcon 3DUse of the Excavator system,The system has the following advantages:

1

Provide precise operation boundaries such as construction design elevation and slope,Intuitive and visual,The construction is efficient and convenient;

2

The system has the function of field measurement.,Avoid the dependence on surveying and setting out and repeated quality inspection in the construction process;

3

Significantly improve the accuracy and efficiency of the operation,Avoid rework,Reduce oil consumption and mechanical wear;

4

Capable of realizing pile-free construction,Dramatically reduce measurements、Auxiliary work such as setting out and piling,It is also suitable for night work.;

5

And that labor intensity is reduce,Reduce the number of personnel,Reduce the comprehensive cost of construction and improve the safety of construction site。

The reconstruction and expansion project will be conducive to promoting the construction of Hefei's comprehensive transportation hub.,Optimize the layout of transportation network,Speed up the construction and development of regional comprehensive transportation system。After the completion of Hefei Xinqiao Airport Phase II Reconstruction and Expansion Project,It will meet the passenger throughput of 40 million passengers in 2030.、Cargo and mail throughput of 350,000 tons、Aircraft take off and land 30.The development demand of 50,000 sorties。Its perfect comprehensive transportation hub function、Unique exterior configuration of the terminal building,It is conducive to improving the comprehensive support capability of the airport.,Speed up the construction of regional aviation hub,Promoting regional economic and social development,It will surely become a bright pearl in the Yangtze River Delta region.。

Contribution:Mechanical Control DepartmentWTQ