China Railway Construction Heavy Industry Co., Ltd. launched the world's first variable diameter inclined shaft TBM to help the construction of Pingjiang Pumped Storage Power Station in Hunan

August 16, 2023

August 15,At the construction site of the State Grid Xinyuan Hunan Pingjiang Pumped Storage Power Station,One can achieve 50°Super large inclination angle continuous climbing、6.Rock TBM with variable diameter excavation from 5 m to 8 m(TBM)Successfully initiated,This marks the start of construction of the first 700-meter headrace tunnel in central China.,The project will fill the ultra-high water head.、Global blank of full-section mechanized construction of diversion tunnel of hydropower station with super-large slope and two-stage inclined shaft。

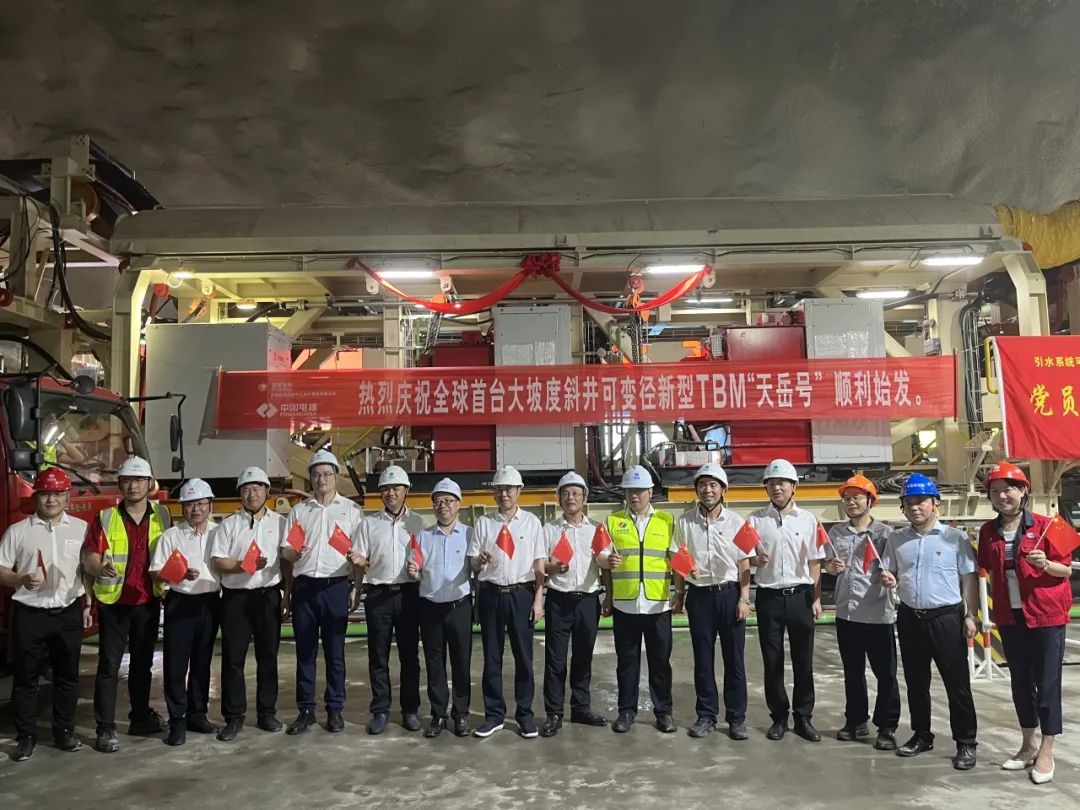

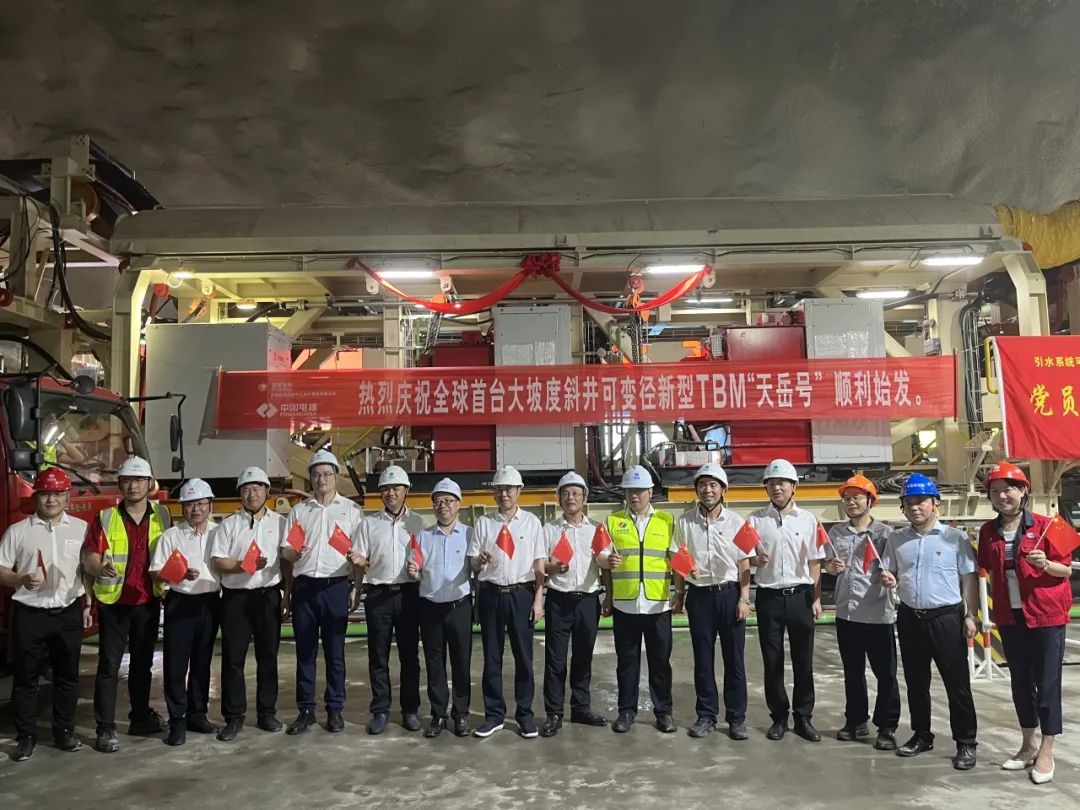

The world's first variable diameter inclined wellTBMOriginating

The engineering tunneling equipment is called“Tianyue”,The total length is 87 meters、Total weight about 900 tons,By China Railway Construction Heavy Industries、State Grid Xinyuan Hunan Pingjiang Pumped Storage Company、Jointly built by Sinohydro Bureau 8。“Tianyue”Initiated launching without guide platform、50-degree large-inclination crawl tunneling method from bottom to top,Realize 6 in the middle adit.5 to 8 m reducer,Finally, it drove out of the upper adit.,Two-stage diversion inclined shaft adit can be realized、Full-section continuous excavation of inclined shaft、Primary support one-step forming。

Hunan Pingjiang Pumped Storage Power Station is located in Fushoushan Town, Pingjiang County, Yueyang, Hunan.,At present, the construction of the project has entered the main peak period.,Upper Reservoir、Lower reservoir、Underground powerhouse、Comprehensive construction of 51 working faces such as water diversion system,Engineering adit、Inclined shaft、Shaft、Full-section mechanized operation is adopted for both large and small sections.。

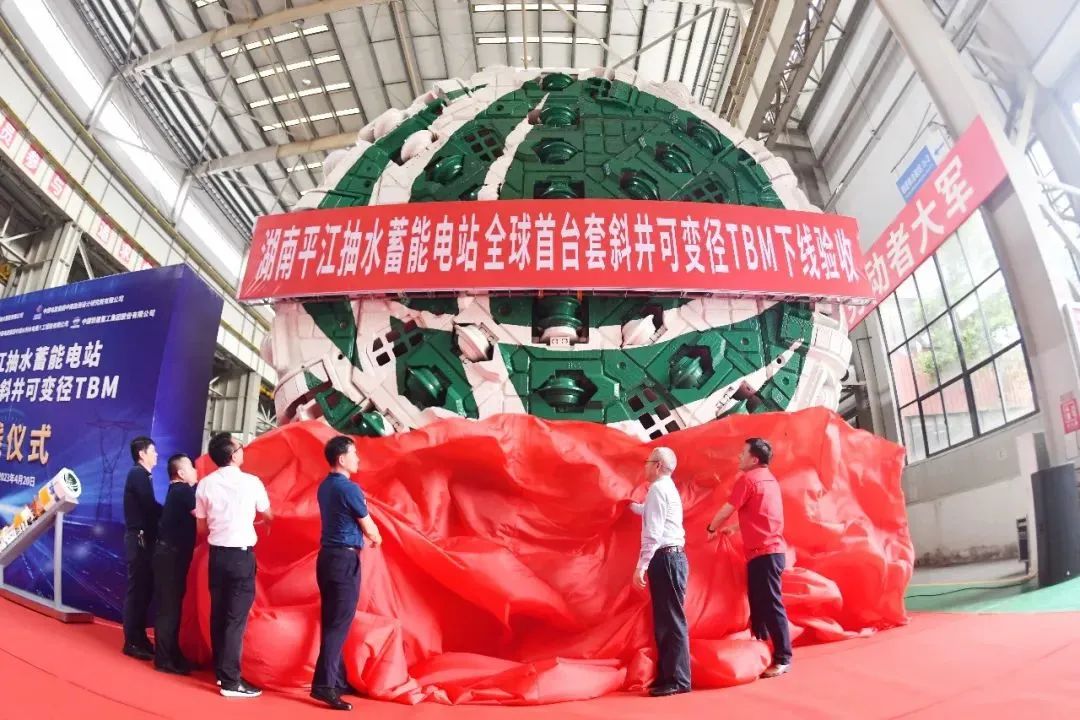

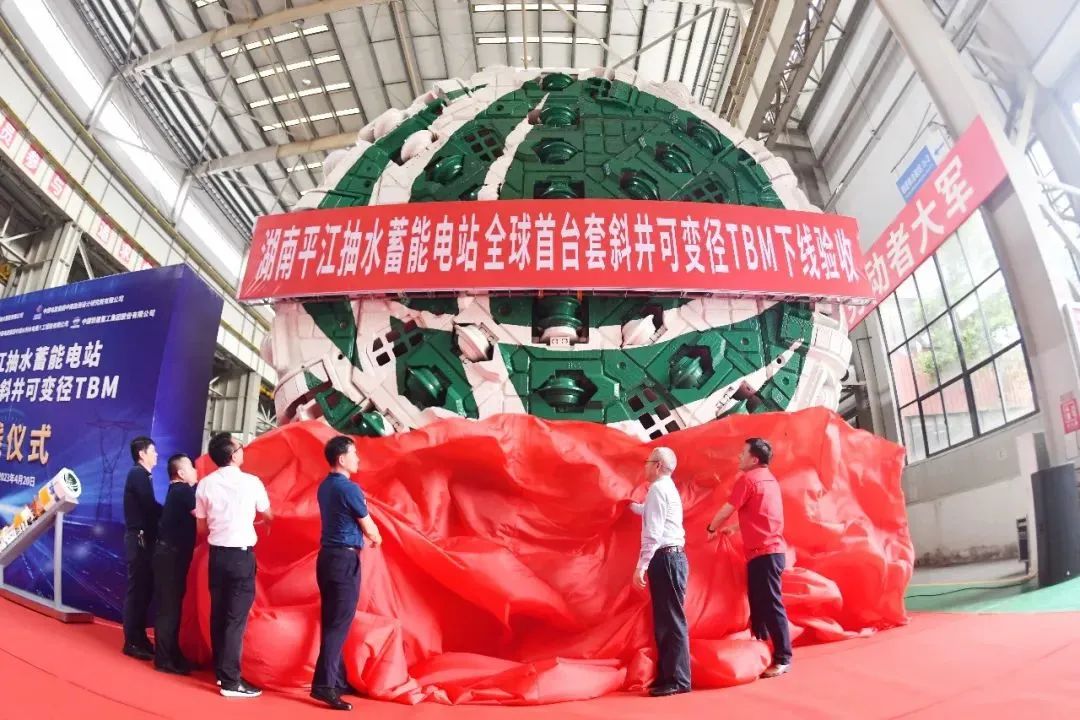

The world's first variable diameter inclined wellTBMOff the line

It is reported that,The diversion tunnel of the project is the key part of the hydropower station construction.,The rated head of the power station is 648 meters.,The maximum lift is over 700 meters.,Height drop of diversion inclined shaft tunnel,Compared with the tallest building in Hunan at 452 meters“National Financial Center”And 196 meters higher.。If conventional pilot shafts are used+Drilling and blasting method,It can not effectively cope with the complex environment of super-large inclination.,Extremely high security risk。

In order to speed up the construction of pumped storage power station,Assist“Double Carbon”Goal achieved,The project has been vigorously promoted“Mechanization and personnel reduction、Automated replacement、Intelligent unmanned”Green Intelligent Construction Concept,Actively explore the application of advanced construction methods and new equipment。The project adopts variable diameter.TBMConstruction,To a certain extent, it solves the high risk of diversion inclined shaft construction in pumped storage power station.、The construction is difficult、Poor quality molding and other industry problems,To promote the high-quality development of pumped storage power stations、Break the technical bottleneck、The realization of autonomous and controllable technology has a demonstration effect.。

The world's first variable diameter inclined wellTBMPanorama of the workshop

Combined with engineering construction problems,“Tianyue”The R & D team spent five years tackling key problems.,Initiatively put forward the compound anti-running system with large gradient,For the first time, it has conquered the ultra-small vertical curve turning with a radius of 50 meters.、Large-range reducing of large-section cutter head and shield body、Initiation without guide station、There are 8 technical problems in the industry, such as continuous slag tapping in complex processes.,Carry out slag tapping、Support、10 innovative tests such as maintenance and material transportation,So that that equipment can realize the flat hole efficiently、Continuous driving of inclined shaft,The applicability of the equipment to complex underground caverns is greatly enhanced.。

It is reported that,State Grid Xinyuan Hunan Pingjiang Pumped Storage Power Station“Fourteen five”Major energy projects,The total investment is 8.8 billion yuan.,Total installed capacity is 1.4 million kilowatts,Design annual power generation 10.0.9 billion kilowatt hours,Pumping capacity 14.5.3 billion kilowatt hours,The power station plans to put the first unit into operation by the end of 2025.。