01

Industry background

Cement concrete pavement,Also known as“White pavement”,Because of its high strength,And that durability is good,The advantage of low construction cost is widely used.。But with the increase of service life,,Poor road driving comfort、Noisy、Long maintenance cycle after damage、Traffic impact and other shortcomings are gradually highlighted.。

With the rapid development of economy,Comfort of people drive on that road surfaces、There are higher requirements for safety and beauty.,Many are close to or beyond the design life.“White pavement”They all need to be transformed into black asphalt pavement with better performance.,The so-called cement pavement.“ White ”Change“ Black ”。

At present, cement pavement“ White ”Change“ Black ”There are three main technical solutions.:

01

01

Excavate the old cement slab,Local subgrade trimming,Re-pave the water-stabilized layer,The asphalt layer is then spread。

02

The original cement slab is broken(Crushing with multiple hammers、Resonance crushing, etc),Newly laid water stable course,The asphalt layer is then spread。

03

03

Keep the original cement slab,A stress absorbing layer is additionally arranged(Or a sandwich material such as a glass fiber grating, etc.),The asphalt layer is then spread。

Cement pavement“ White ”Change“ Black ”DifficultiesLie in:

❖Bond quality between asphalt surface course and cement slab;

❖Effect of Reflection on Cracking Prevention of Original Cement Pavement;

❖Influence of Pavement Elevation after Reconstruction on Auxiliary Facilities;

❖Construction period and traffic impact;

❖Energy saving and environmental protection、Low-carbon construction。

02

Technical introduction

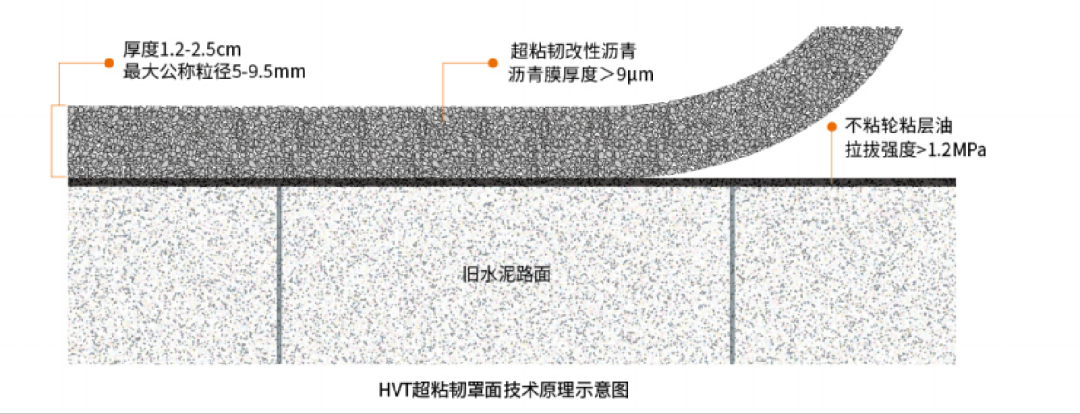

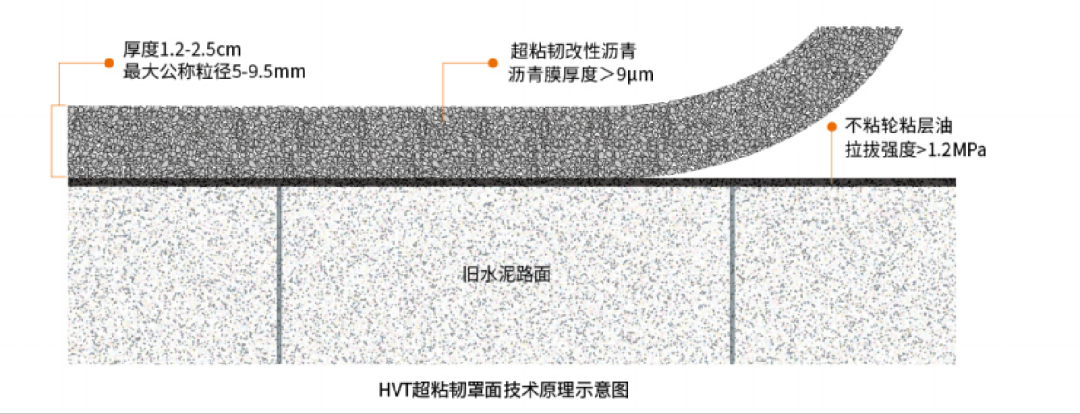

HVT(High-Viscosity-Toughness)Super Tough Overlay Technology,Mainly for cement concrete pavement surface polishing、Cracks and other diseases,Emulsified asphalt tack coat oil by first spreading a non-tack wheel,Then the hot mix super viscous modified asphalt mixture with special gradation is paved.,Rolled to thickness of 1.2-2.5cmHas skid resistance、Crack resistance、High-performance ultra-thin wear layer technology with noise reduction characteristics。

HVTThe construction process flow of super viscous and tough overlay is shown in the figure below.:

Ying DaHVTSuper Tough Overlay Technology Has Five Advantages:

● Ultra-strong interlayer bonding。Strong interlayer bonding force,Ffectively prevent peeling between cement board layer;

● The performance is excellent,And that durability is good。Has skid resistance、Crack resistance、Resistance to flaking、Noise reduction and the like.,Service life up to 5~8 years。;

● Does not affect the elevation。Typical thickness 2.0cmNo need to adjust ancillary facilities,Ideal for elevation and load sensitive scenario;

● And that construction period is short,Do not disturb the people。Less equipment、Fast,About 1 after the endhOpen to traffic;

● Energy saving and environmental protection。Compare to conventional overlay solution,Reduce raw material by about 80%,Reduce carbon emissions by about 70 percent%。

HVT Ultra-tacky facing and conventional facing

HVTThe scope of application of the Super Tough Overlay Technology includes:

expressway、National and provincial trunk lines、Tunnel、Bridge deck cement pavement“ White ”Change“ Black ”Engineering;

Urban road cement pavement of various grades“ White ”Change“ Black ”Engineering。

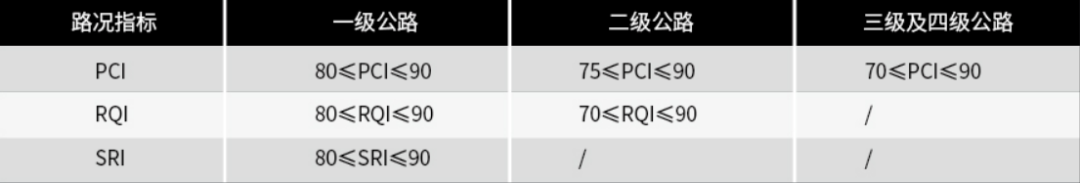

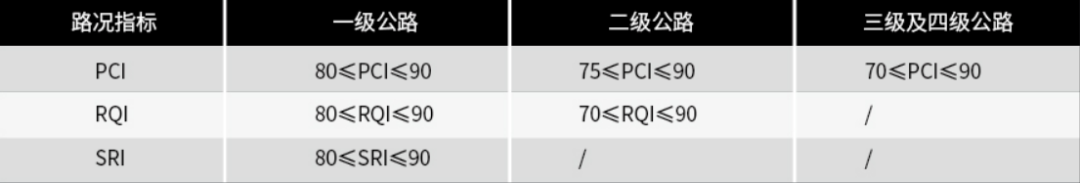

Basis《Technical code for preventive maintenance of highway cement concrete pavement》(DB51/T 28000-2021),Detect the original road surfacePCI、RQI、SRIIndicators,Unsatisfactory road sections shall be handled in advance.。

HVTRoad condition level of each grade of cement pavement applicable to super viscous and tough overlay

03

Core technology

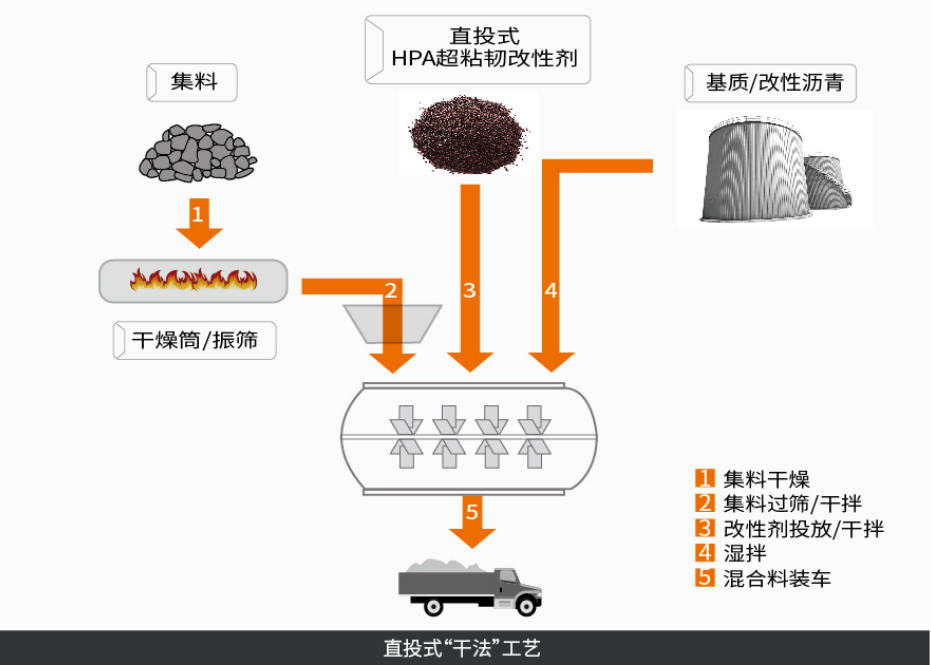

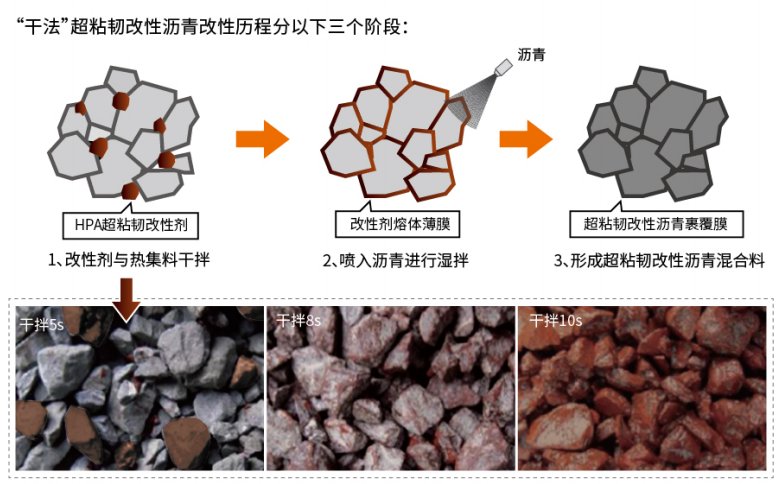

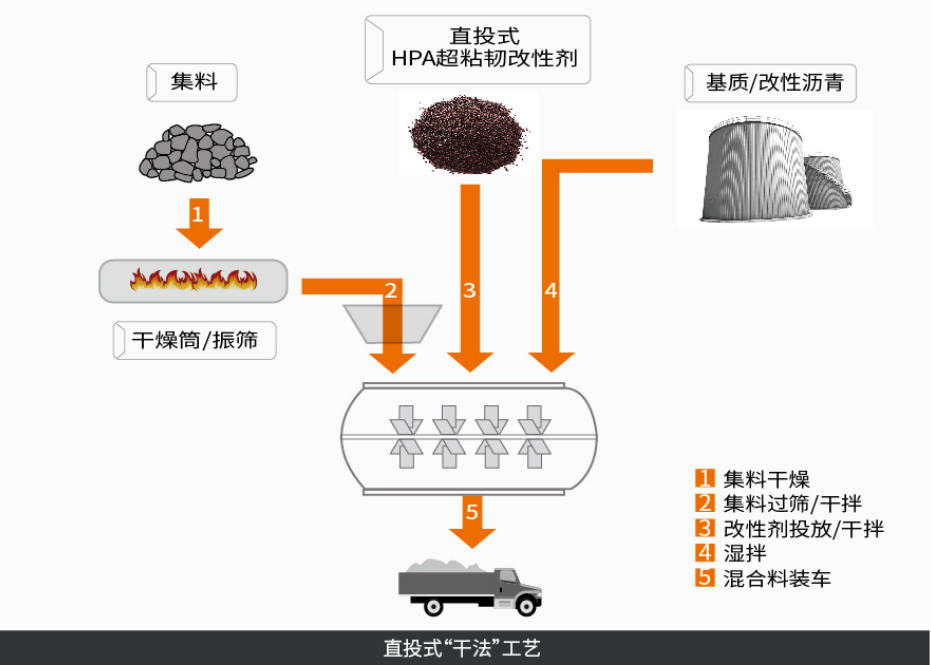

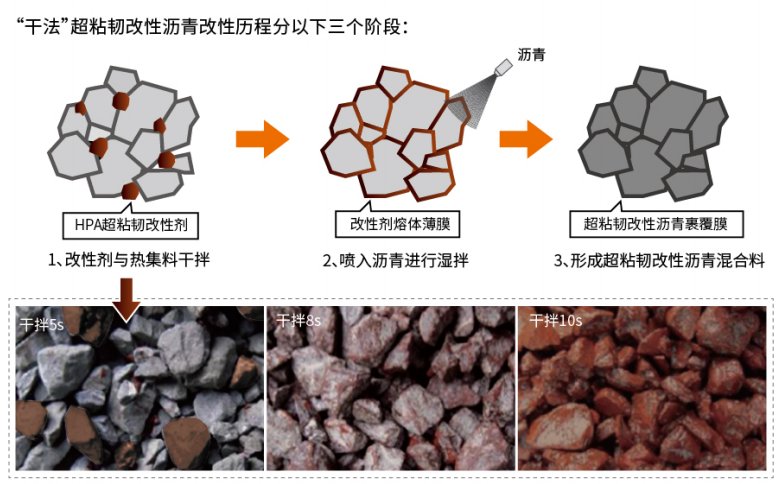

Core technology oneHPADirect delivery“Dry method”Production process of asphalt mixture

Direct delivery“Dry method”Process refers to the first mixing in the mixing station.HPAThe super viscous and tough modifier is added into the aggregate for dry mixing(About 10~15s),The substrate is then added/Modified asphalt wet mix,So that that super-viscosity-toughness modify asphalt mixture is produced。

Direct delivery“Dry method”The process has the following advantages:

● And that proces flow is simple,Quality supervision is easy,The construction flexibility is high,Energy saving and environmental protection;

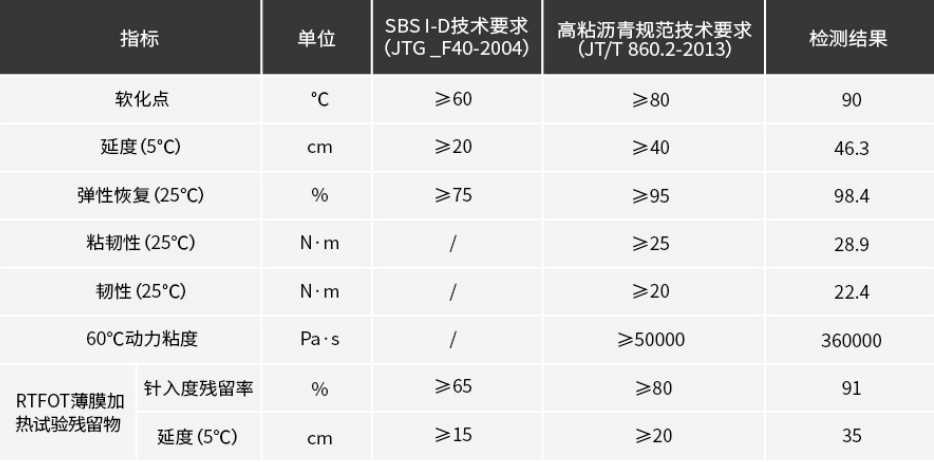

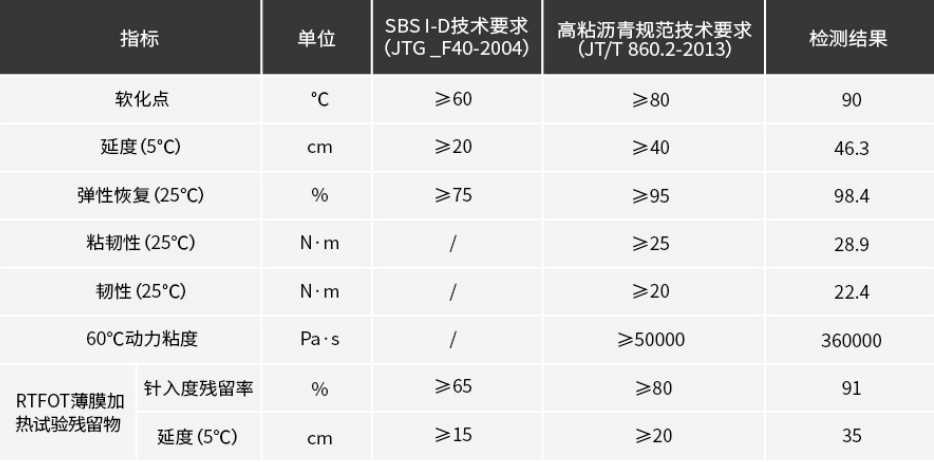

HPAKey technical parameters of super viscosity-toughness modifier performance

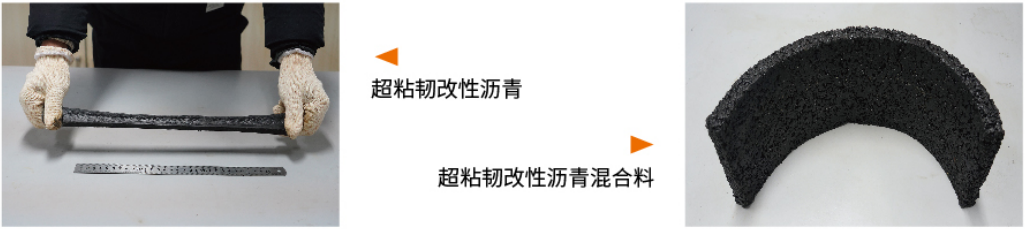

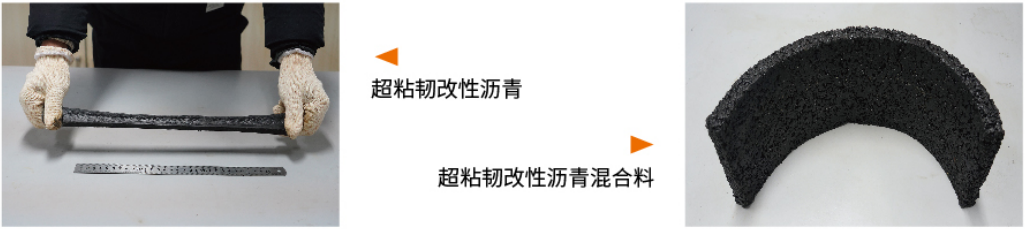

● HPAThe super viscosity and toughness modifier has good compatibility with asphalt,Easy to melt and disperse,The produced super viscous and tough modified asphalt has excellent performance.;

Comparison of Key Technical Parameters of Super Viscosity and Toughness Modified Asphalt

● The super sticky and tough modified asphalt mixture has high cohesiveness、Strong toughness,The road performance is excellent,And that durability is good。

Core technology twoHPENon-stick wheel emulsified asphalt

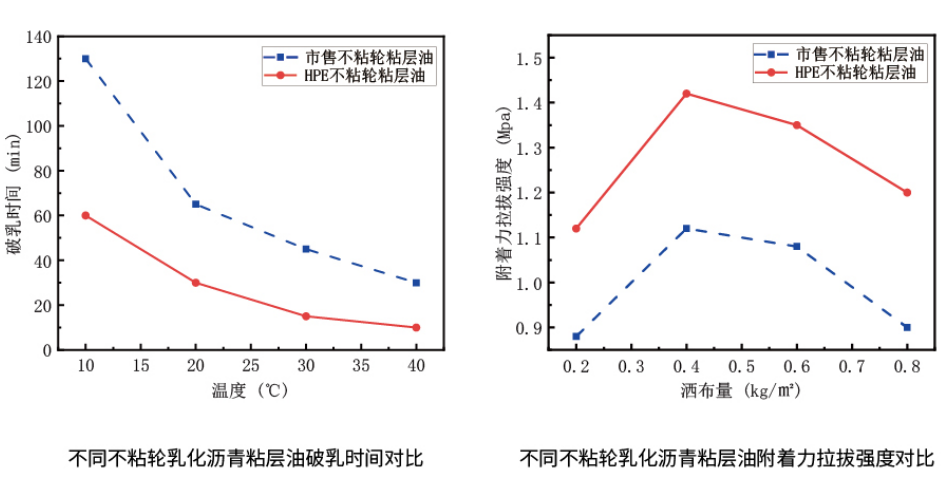

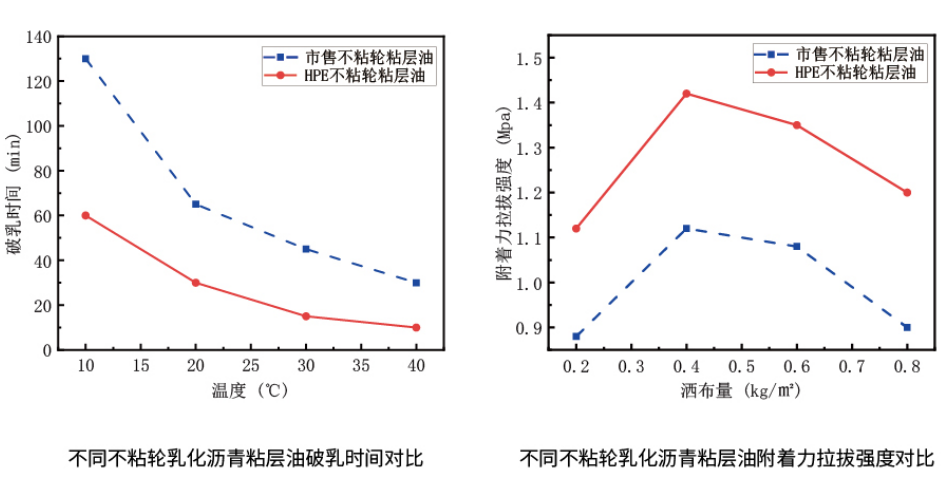

Emulsified asphalt, as a waterproof bonding layer, is one of the keys to the success of ultra-thin overlay,The bond strength between overlay and original pavement directly affects the durability of pavement.。

HPEThe characteristics of non-stick wheel emulsified asphalt tack coat oil are as follow:

● Good mobility,And that waterproof performance is excellent。It penetrates into the pores and micro-cracks of the pavement and forms a complete asphalt film,Avoid water damage caused by rainwater infiltration;

● Rapid demulsification、Quickly develop strength。Implement 0.5hNon-stick wheel effect of internal rapid paving and skip car driving,Improve construction efficiency and quality;

● The bonding force is strong,High drawing strength。Improve the bonding force between the cement board and the finish coat,It is firmly bonded to form an integral structure.。

Common emulsified asphalt andHPEComparison of construction site effect of non-adhesive wheel emulsified asphalt tack coat

Common emulsified asphalt andHPEComparison of Hand Sticking of Emulsified Asphalt for Non-stick Wheels(42C)

Core technology threeIntermittent dense graded asphalt mixture

Gradation type has an important influence on the pavement performance of asphalt mixture。HVTIntermittent dense gradation shall be adopted for super viscous and tough overlay.,Existing solid mineral aggregate skeleton structure,But also has higher compactness.,Its characteristics are as follows:

● It has good surface structure and anti-skid and noise reduction performance.;

● Excellent spalling resistance、Crack resistance and water damage resistance,And that durability is good;

Intermittent dense grading

Intermittent dense grading

Effect drawing after construction

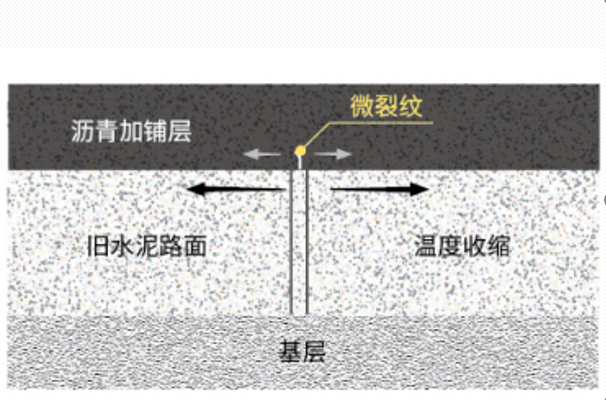

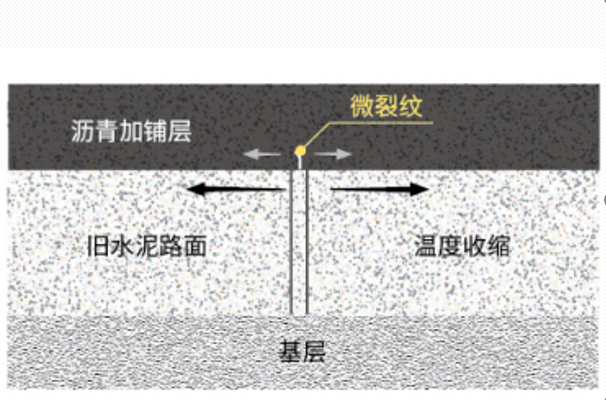

“ White ”Change“ Black ”Cause of reflection crack:

▶Formation of reflection crack

Reflective cracking is caused by stress concentration in the upper asphalt overlay due to the displacement near the joints or cracks of the cement slab.,Traffic load and temperature effect are the two most important factors causing reflection cracks.。

Temperature type reflection crack

Temperature type reflection crack Load type reflection crack

Load type reflection crack

▶Propagation of reflection crack

Once the microcrack is formed,Ambient temperature、The repeated action of traffic load will make the reflection crack spread to the whole road.,Finally, the road surface is damaged.。

Schematic diagram of reflection crack propagation

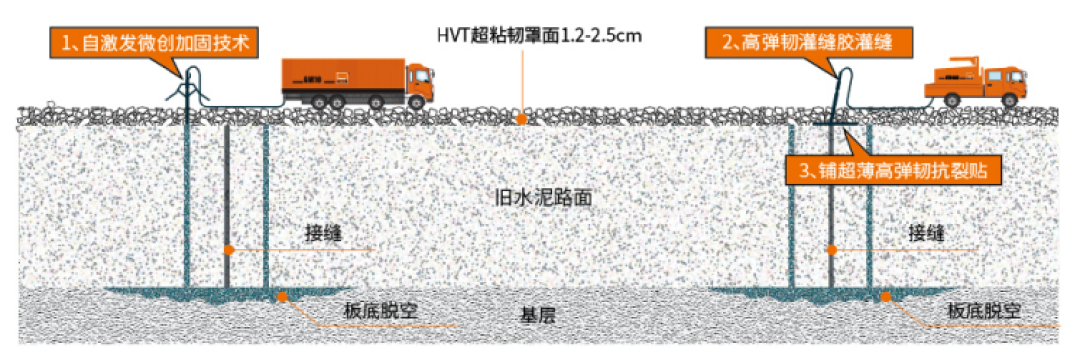

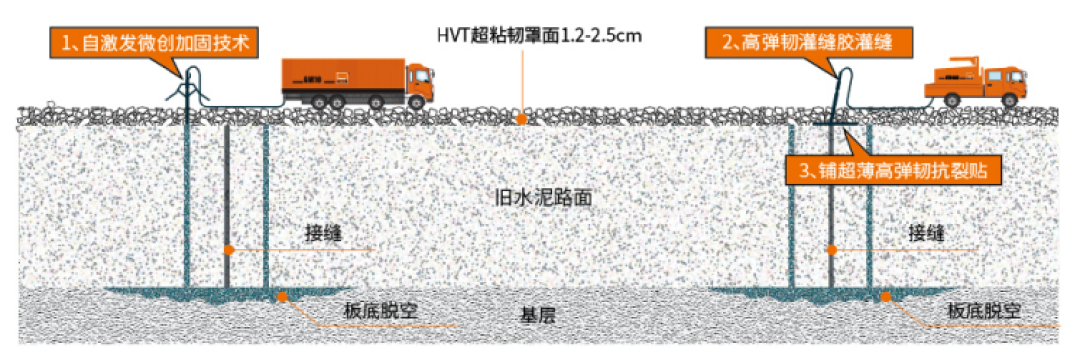

Ying Da“ White ”Change“ Black ”Complete set of technology for prevention and treatment of reflection crack:

Active and passive combination mode defense system,Prevent and slow down the occurrence of reflection cracks。

Active prevention

● 1.The self-excitation minimally invasive reinforcement technology independently developed by Yingda is used to carry out local grouting at the bottom of the slab.,Ffectively treat void between plates and eliminate relative displacement between plate,Reduce the possibility of reflection cracks from the source;

● 2.The high elastic and tough joint sealant independently developed by Yingda is adopted.,Large elasticity、Strong viscosity、Anti-aging、Super resistant to low temperature,Further reduce the possibility of reflection cracks from the source;

Passive resistance

● 3.It adopts the ultra-thin high-elasticity anti-cracking paste independently developed by Yingda.,The thickness is thin、Strong self-adhesion、High tensile strength,Ffectively slow down that propagation of reflection crack;

● 4.AdoptHVTSuper Tough Overlay,Its excellent adhesion and toughness are combined with anti-crack fibers.,Ffectively slow down that propagation of the reflection crack。

05

Construction process

1、Disease detection of original pavement

1、Disease detection of original pavement 2、Self-excitation minimally invasive reinforcement

2、Self-excitation minimally invasive reinforcement 3、Grouting effect detection

3、Grouting effect detection 4、Crack pouring

4、Crack pouring 5、Fine milling

5、Fine milling 6、Road sweeping

6、Road sweeping 7、Crack pouring again

7、Crack pouring again  8、Stick the anti-crack paste

8、Stick the anti-crack paste 9、Mixing super viscous and tough mixture

9、Mixing super viscous and tough mixture  10、Spray non-stick wheel tack coat oil

10、Spray non-stick wheel tack coat oil 11、Paving and rolling of mixture

11、Paving and rolling of mixture  12、Open to traffic

12、Open to traffic

01

01

03

03

Intermittent dense grading

Intermittent dense grading

Temperature type reflection crack

Temperature type reflection crack Load type reflection crack

Load type reflection crack

1、Disease detection of original pavement

1、Disease detection of original pavement 2、Self-excitation minimally invasive reinforcement

2、Self-excitation minimally invasive reinforcement 3、Grouting effect detection

3、Grouting effect detection 4、Crack pouring

4、Crack pouring 5、Fine milling

5、Fine milling 6、Road sweeping

6、Road sweeping 7、Crack pouring again

7、Crack pouring again  8、Stick the anti-crack paste

8、Stick the anti-crack paste 9、Mixing super viscous and tough mixture

9、Mixing super viscous and tough mixture  10、Spray non-stick wheel tack coat oil

10、Spray non-stick wheel tack coat oil 11、Paving and rolling of mixture

11、Paving and rolling of mixture  12、Open to traffic

12、Open to traffic