Reduce the environmental impact of doing business,It's EnglandBreedonOne of the explicit objectives of the Group's sustainable development strategy。For this reason,The company recently invested in a brand new Anmai in Mansfield, Nottinghamshire.ABA 260 UniBatchAsphalt Mixing Plant,Used to replace the original mixing station。

Regional managerMatthew GelsthorpeExpress:“Mansfield's original Asphalt Mixing Plant has been in operation for nearly 25 years.,Not as efficient and economical as before.。We want a more efficient one.、Reliable new mixing plant,Can significantly reduce energy consumption and carbon dioxide emissions。Sustainability of bitumen production is critical,We hope to show the market through the new equipment.BreedonA commitment to environmental protection。”

The company wanted to select a machine that could use a high percentage in the mix.RAP,And can produce warm mix、Mixing plant for cold and hot mix asphalt。As part of a sustainable development strategy,They are very concerned about the energy consumption of the mixing plant.。

After market research,BreedonChoose to meet sustainability in all aspect、Reliability and efficiency requirements of AnmaiABA 260 UniBatchAsphalt Mixing Plant。The apparatus has 260 t/hThe output of,Offers great customization potential with numerous options and easy integration of future technologies,Efficient drying and heating techniques are used.,Save energy、Reduce emissions,Resulting in cost savings。

The new Anmai mixing plant was built in the southeastern suburb of Mansfield.,It has been put into full production in early 2023。

The drying and heating of the material is in a length of 10. m、Diameter 2.5 mIn a counterflow drum.。Unique AnmaiRAH50 intermediate ring type regenerating roller,Can be added up to 50%YesRAP。In addition,The dedusting system of the mixing plant recovers the mineral powder from the exhaust gas of the Burner,And adopt the 57000 Nm3/hExhaust fan and 26 mA tall chimney,Vent the purified gases and vapors to the atmospheric。

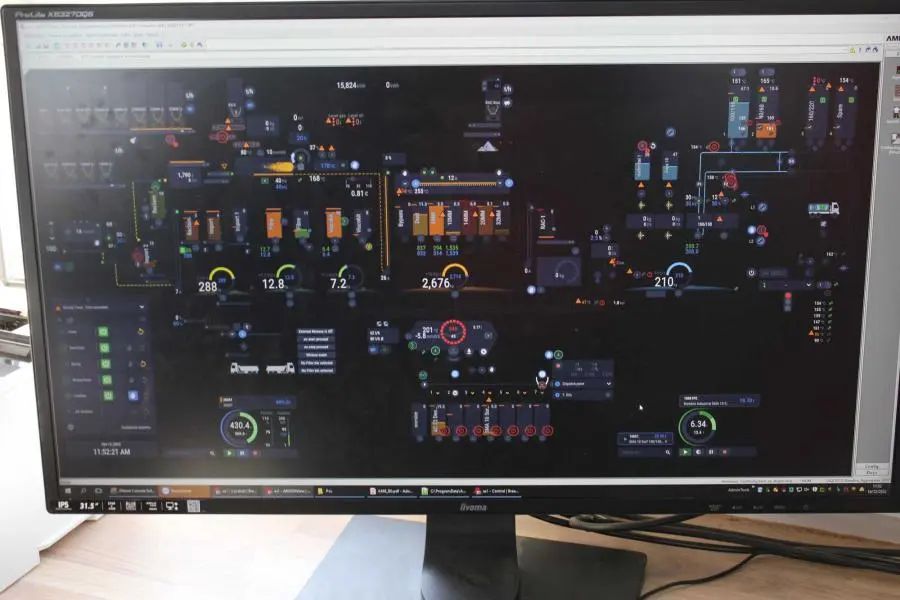

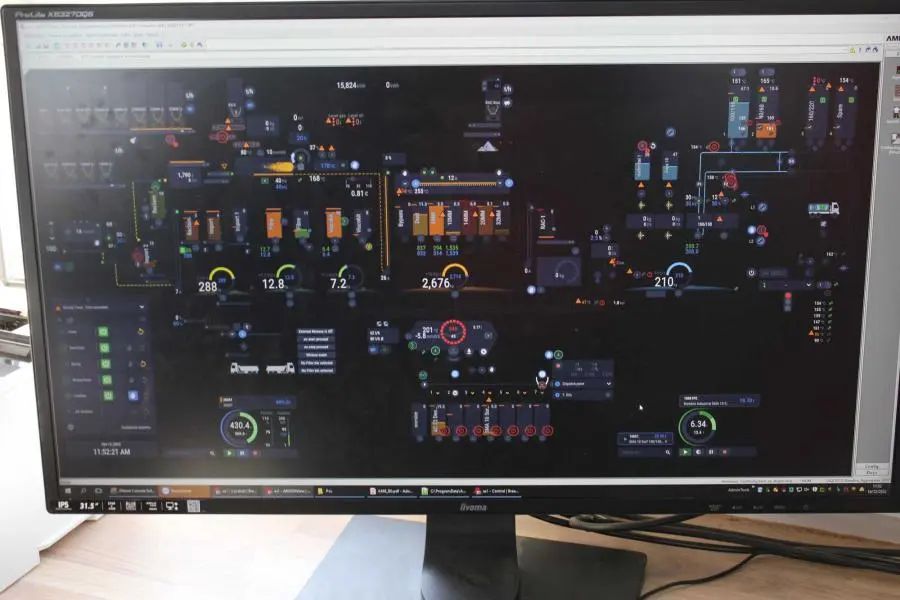

The mixing plant adopts the future-oriented Anmaias1 Control system,Combine proven software with proven industrial hardware,Provides comprehensive control and monitoring capabilities,And the network and management optimization are carried out.。From the Mansfield factoryABA 260 UniBatchNot only does it have Britain's firstas1 Argon ViewInterface,And configured with a newEcoViewAndPIPAdd-on module。

Argon ViewIs suitable for asphalt、Cement Concrete Mixing Plantas1 New user interface for the control system。It's intuitive、Simply provide real-time updates of production status,Helps operators track the entire production process,Improve efficiency and productivity by taking advantage of the advanced features of the ANMAI plant。

EcoViewModules are designed to optimize production from an ecological and economic perspective。Operational data is continuously recorded,And presented in a concise form.,Energy consumption per ton of mix for the plant operator、Information such as energy costs and CO2 emission values。By comparison with historical data or target values,Trends and action needed can be identified,In order to promote the energy optimization of the mixing plant operation,Help eliminate energy waste。

Another add-on modulePIPProvides operators and customers with anytime, anywhere access to critical plant data。Daily production quantity、The latest production details and the status of the mixing station are uploaded to the Anmai cloud server.,This information is available on a desktop computer、Browser access on tablet or smartphone。

Compared to the old mixing plant,AnmaiABA 260 UniBatchAsphalt Mixing Plant used 18MWBurner,Reduced carbon dioxide emissions;From conveyor belt to drying drum、Burner、Exhaust fan and asphalt pump,Are equipped with variable frequency speed regulators.,Helps reduce noise levels and energy consumption。

“We converted a non-recycling plant to potentially use 100,000 tons per yearRAPThe factory,This is forBreedonThis is an important step forward for the company and the UK market.。”Matthew GelsthorpeSay,“Although this is a huge investment.,But it won't be the last.。”