When the German Lion“Yu”See American Hardcore Weapon

Striking design,A fully functional device,As well as technology adaptation improvements for customized needs,These are the specialties of Mann's personalized customization.。Recently,Mann Personalized Customization Center Adds More Technological Work——Han RuisenULTIMAAXRubber suspension。

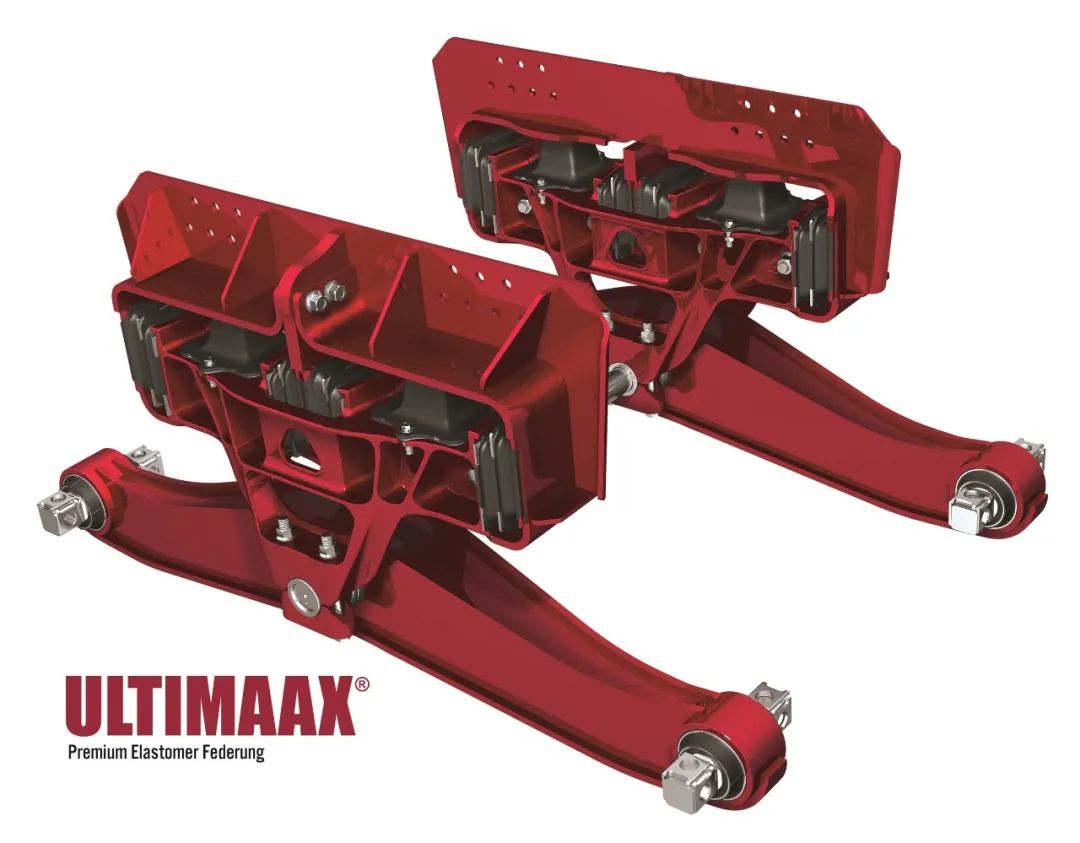

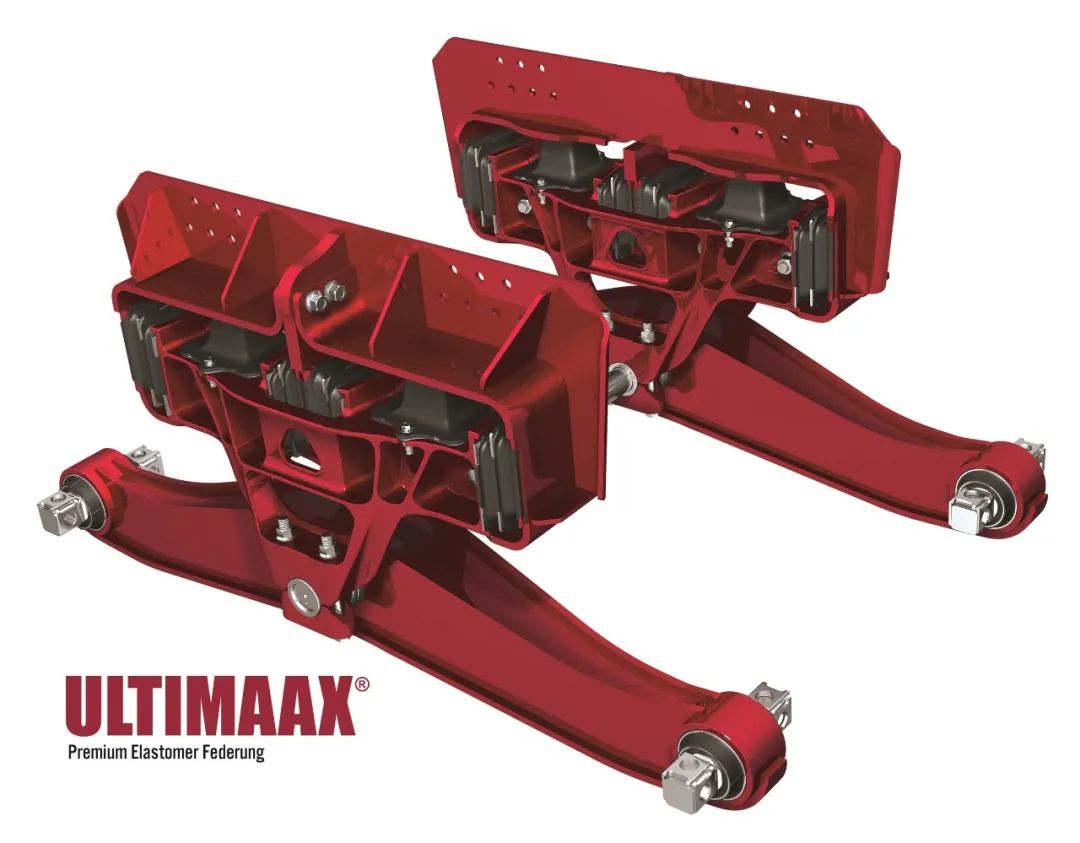

The force bear part of that suspension system is made of rubber,Simple but sturdy construction,The durability is strong,Light weight,Road impact can be better absorbed,Improve driving comfort,It is an ideal alternative to conventional leaf springs。

Mann's Customization Division(MAN Individual)Since its inception,Always be oriented to meet customer needs,Technical tuning and body trim for individual application requirement,And other industry-specific customization and modification services。

Recently,Mann's Customization Department Joins Hands with Famous Suspension Manufacturer Hanresen(Hendrickson),A new option added to the broad portfolio——Hexion mounted on the rear axle of the VehicleUltimaaxRubber suspension system,By virtue of itLightweight、Comfortable、Advantages such as compatibility with heavy loads,Compromise between Hardcore and Comfort for Heavy Duty Truck,Become the past tense。

Head of Personalization at MannJohannes ThalmannMr. Wang said:“Nowadays,More and more Trucks are beginning to be customized for their specific transportation tasks.,Particularly in construction and off-road applications。Selection of loading structures and components for better applicability,Control of Truck performance and fleet ownership costs,Vital。”

“Mann has always seen himself as‘Implementation of special solutions on Vehicles’The promoter of,By meeting the special needs of the Vehicle and providing personalized solutions,So as to create added value for customers.。Nowadays,Through the joint efforts with the partner Hanruisen,We're rightTGXThe rear axle unit has been further innovated.。Future,Our customers will have more opportunities to customize Vehicles in Mann to meet their specific needs.。”

“Compare to conventional leaf spring suspension,First,ULTIMAAXRubber suspension technology for greater durability;Secondly,Models with rubber suspension are lighter than those with leaf spring suspensionAbout 250 kilograms.,With the improvement of lightweight level,,Carbon dioxide emissions will also be reduced.。”

“Due to low steel consumption and no additional heat treatment,In the process of production,In total, each rear axle unit canDecrease by about 1.0 tonnes of CO2 emissions,”General Manager of Hanrenson EuropeHelfried JelinekExpress,“As a long-term partner of Mann,We are very happy to be able to offer their products.ULTIMAAXThis innovative suspension solution。”

Due to the personalization of heavy Trucks(Uch as a concrete mixer Truck、Dump Truck、Mine cars and Truck/ 'target='_blank' style='color:blue;'>Garbage Trucks, etc.)High load quality,Under no-load condition,The comfort of the leaf spring suspension system is poor;While in the case of a heavy load with a high center of gravity,The yaw stability of the Vehicle is also affected。So,Hendrickson has developed a special Vehicle for this type of VehiclesULTIMAAXSuspension system,So that it can be perfectly integrated into Mann's rich product portfolio of personalized customization.。

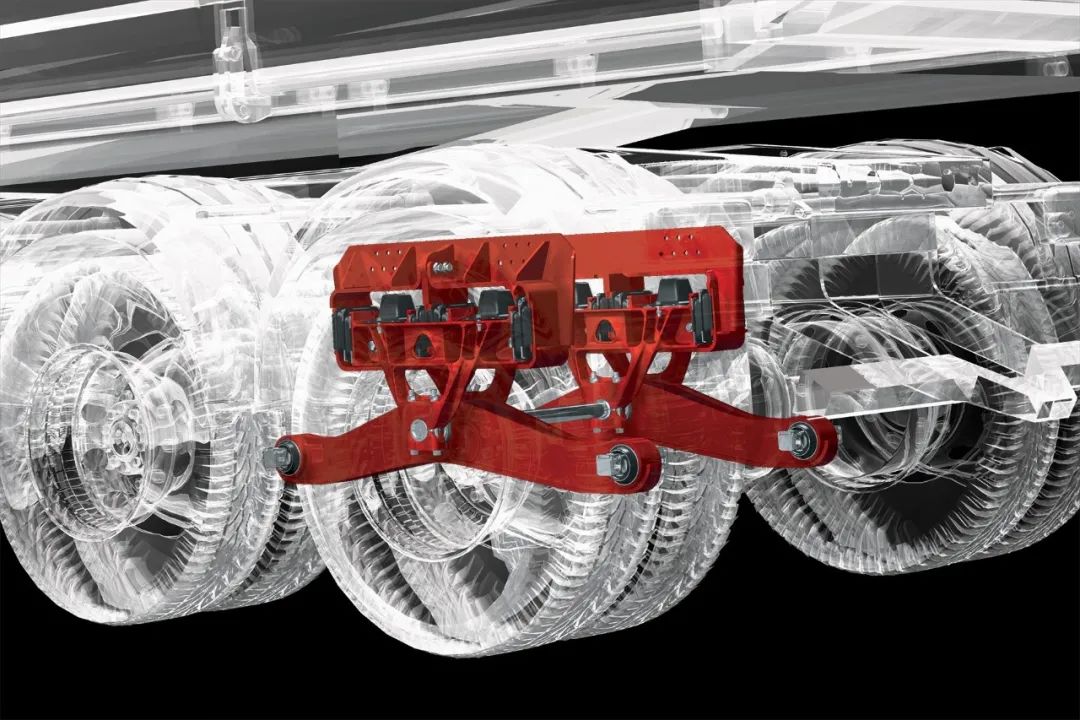

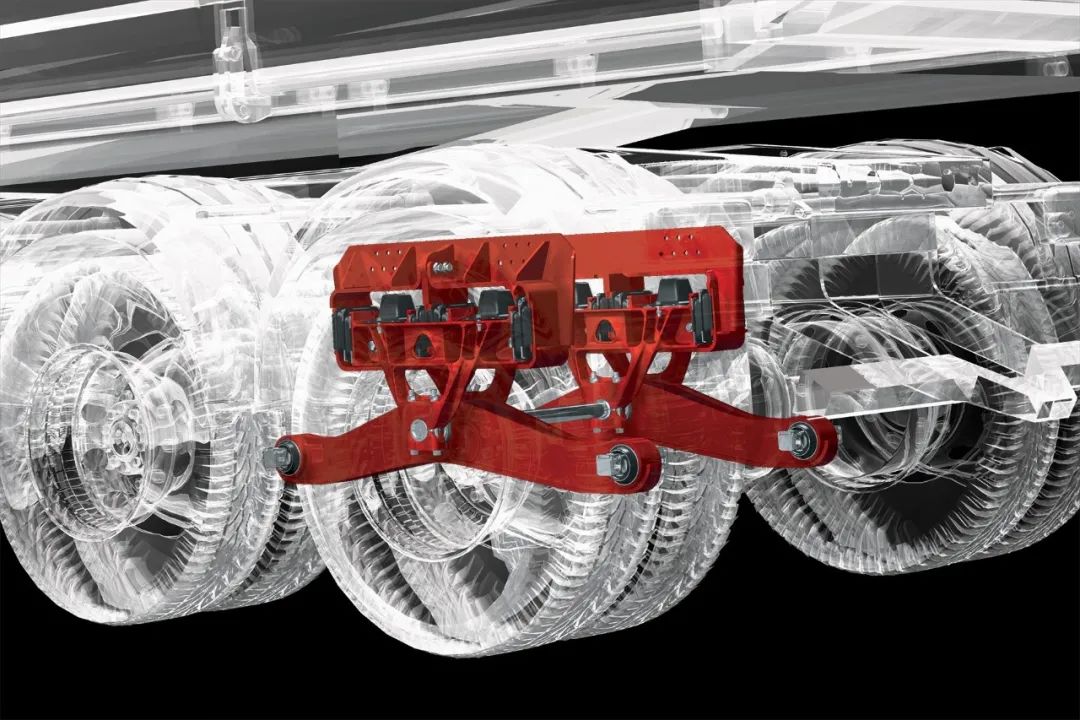

Henryson used by MannUltimaaxThe suspension is a 26-ton load-bearing version.。It's patented by Hanrenson“Walking Beam”Movable cross beam and rubber damping block,In addition to excellent durability and ease of maintenance,And make sureBetter stability、Handling and driving quality,Even in the face of rough and unexpected road conditions.,It can also ensure the stability of the Vehicle when it is loaded and the driving quality when it is running without load.。

The movable beam design of the suspension system adopts a central fulcrum design.,By maintaining as constant a contact between the tire and the ground as possibly,Greatly reduces the impact of turbulence and vibration to the cockpit.、Chassis and body pressure,O as to ensure that the Vehicle runs on the rugged terrain.,Better mobility can be achieved。