Construction machinery and equipment are under high load for a long time.、High strength、Operation under high dust condition,In addition, the quality of operators is uneven.,The lubrication management of equipment has not really been implemented.。According to statistics,There are 60%The above mechanical failures are caused by poor lubrication.。So,Good equipment lubrication management,Very important for equipment maintenance and use。

▲ Traditional manual lubrication of construction machinery and equipment

Science 、 Reasonable 、Economical selection and configuration of centralized lubrication system,Lubricate the equipment timely and effectively.,It can not only greatly reduce the wear and tear of machine parts,,Prolong the service life of the equipment,Improve the operation efficiency of mechanical equipment,Improve operational efficiency。

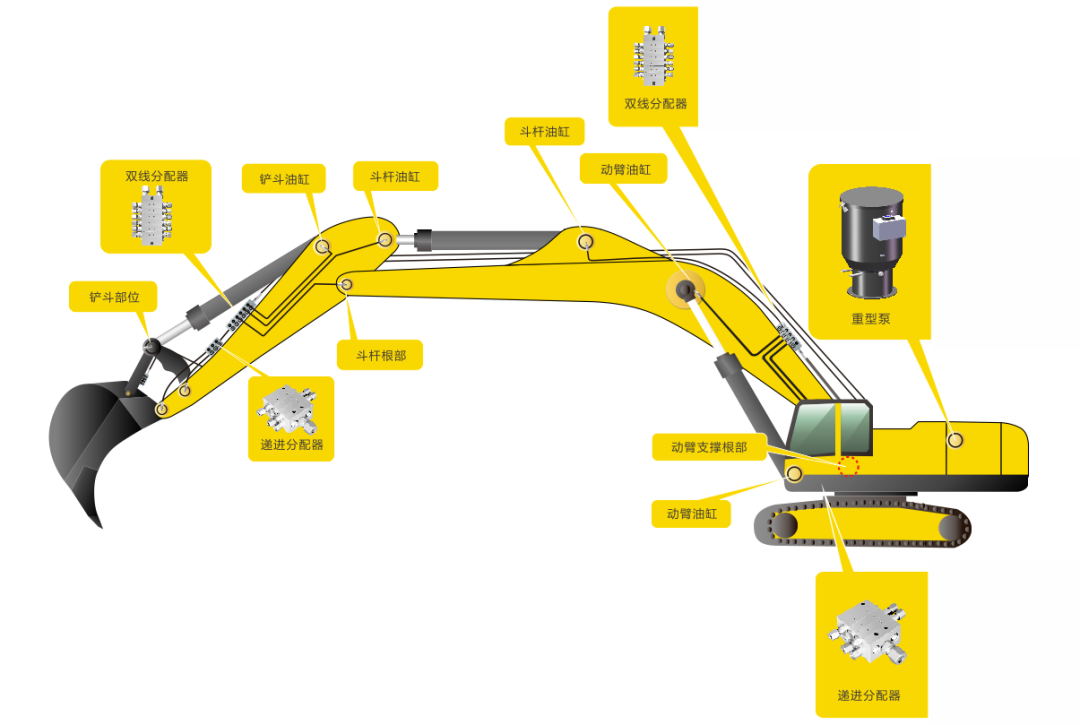

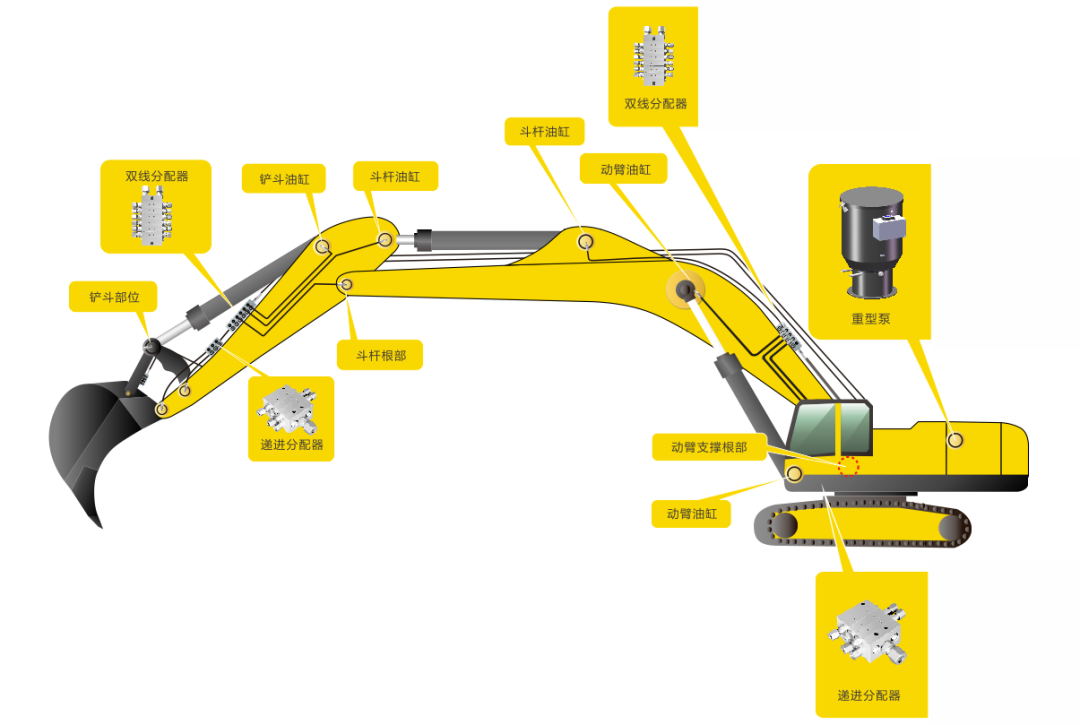

Centralize lubrication system of Excavator with two lines in different area

Value to you

1Reduce downtime for maintenance due to lubrication;

2. Reduce the labor intensity of personnel;

3 Extend the replacement cycle of equipment bearings;

4 Reduce the consumption of grease;

5 Improve the working environment of the equipment,Energy saving and environmental protection。

Technical advantages:

· Zoning control,Different areas,Adjustable oil quantity under different working conditions;

· For different working conditions、Temperature change in winter and summer,In particular, the replacement of the working device leads to a large change in the system fuel ratio.,Dynamically adjustable;

· Zone-controlled large-volume oil drum,Large-volume oil drum capable of supplemen 1 barrel of grease at a times,Can hold one barrel at a time 15Kg,Reduce the frequency of fat supplementation,Built-in grease filling shovel with upper cover opened for grease filling,It is convenient to supplement fat,Avoid grease contamination;

· Double-plunger slide block structures,Stable and reliable,And is convenient to maintain;

· Mechanical reversing valve,Stable and reliable;

· Brushless special motor,High power、Long life、Large displacement,And that grease injection efficiency is high。

Application of centralize lubrication system with two lines and zone in Excavator

▲ 750 Excavator

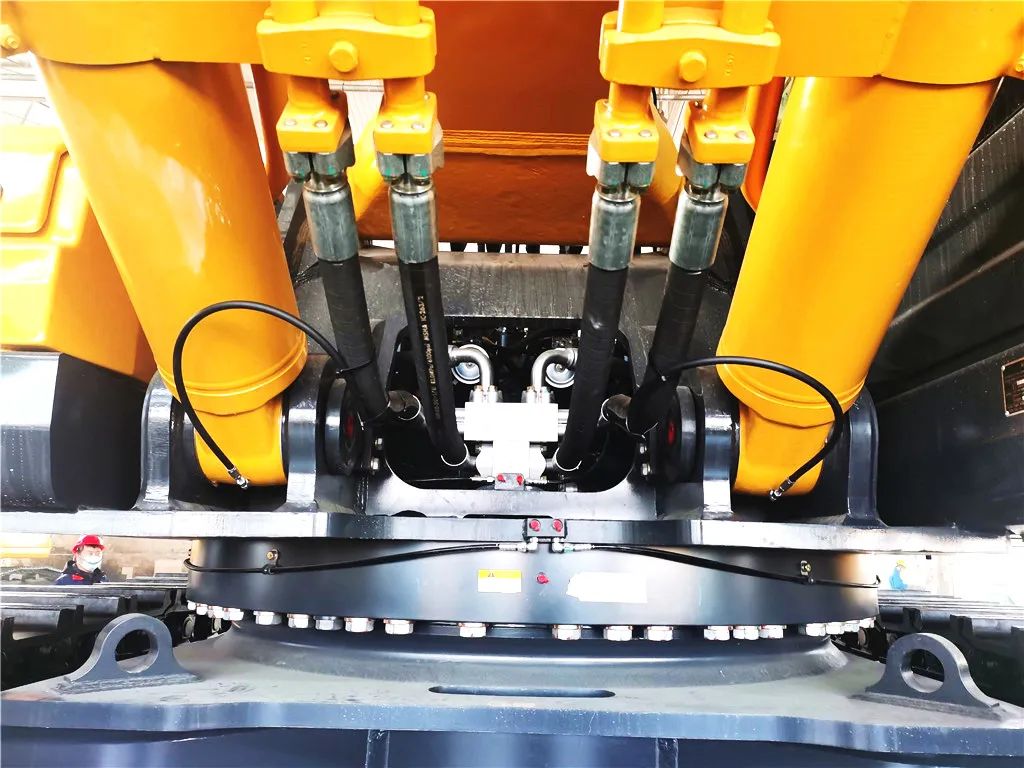

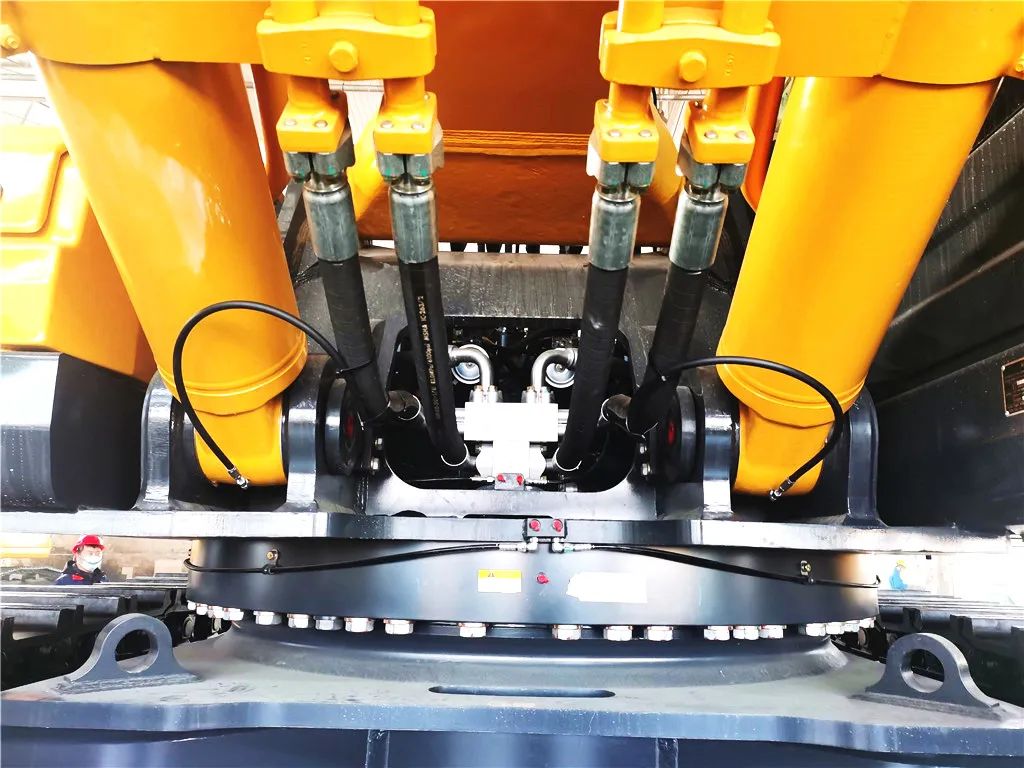

· Installation position of the lubrication pump

· Arm distributor

▲ Lubrication and installation of key parts

Based on actual customer feedback,After installing the central lubrication system,Reduce unplanned downtime,And that labor cost is reduce ,Extended service and maintenance intervals,No need to manually lubricate hard-to-reach lubrication points or lubrication points in areas with harsh operating conditions,Reduce safety accidents。