Application of Nanfang Road Machine Fixed Crushing and Screening Equipment in Anhui Yajiu,Poke the video to see the case↓↓↓,Duration 04:49

Anhui Yajiu Environmental Building Materials Co., Ltd.,Always focus on the production of environmentally friendly building materials。2018,Anhui Yajiu to expand production scale,Choose to cooperate with Nanfang Road Machinery,And has purchased asphalt concrete mixing equipment.、Stabilized soil plant mixing equipment、Dry-mixed mortar mixing equipment、Dry type fine machine-made sand equipment,Build Anhui Yajiu Green Intelligent Building Materials Industrial Park,Set a new benchmark for Huaibei City.。

↑

Swipe right to see more devices

To extend the industrial chain,Construct industrial ecology,2022,Anhui Yajiu decided to enter the field of front-end fixed crushing,And once again work hand in hand with Nanfang Road Machinery.,Adopt the overall solution of fixed crushing and screening of Nanfang Road Machine,Constructed with fine aggregate、Ready-mixed mortar、Commercial concrete、Multi-in-one industrial structure with asphalt concrete as the main part。

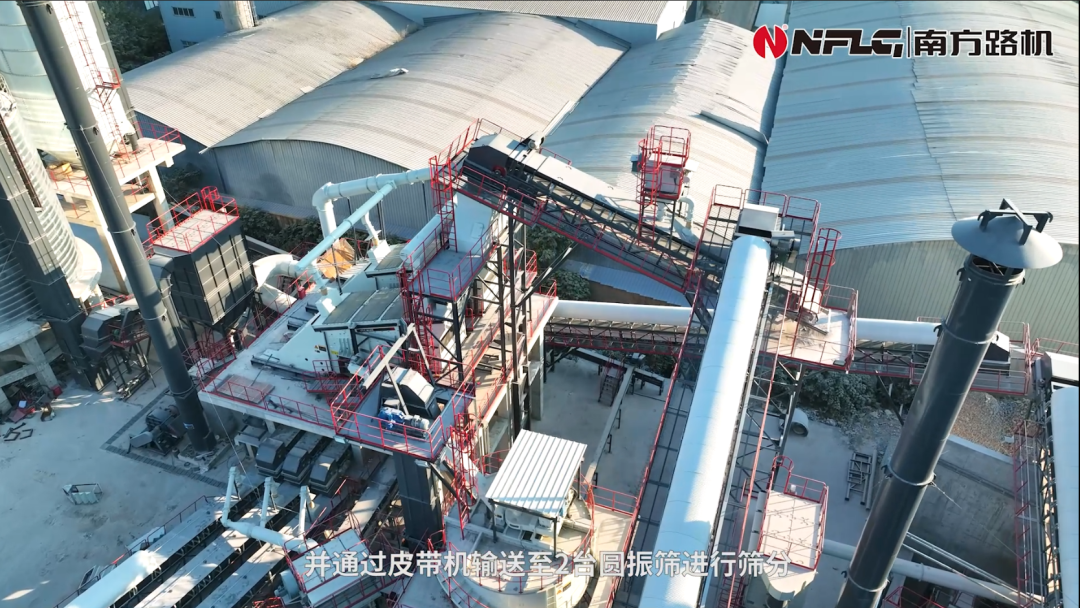

South road machine at the siteFCP300 fixed crushing and screening equipment,Mainly by the feeding equipment、Jaw Crusher、Multi-cylinder cone Crusher、Slag screen、Circular vibrating screen、Storage and transportation、Dust removal equipment, etc.,The production line is highly automated.、And the crushing efficiency is high、The output is as high as 300 tons.,It effectively meets the production capacity demand of Anhui Yajiu.。

01

Factory design,Environmental protection first!

At the scene of Anhui Yajiu,Jaw Crusher for the whole production line、Multi-cylinder cone Crusher、Circular vibrating screen、Dust removal pipeline,Seal,Dust remover,Factory design is adopted.。Compared with the traditional on-site construction of fixed crushing,Nanfang Road Machinery will transport the components to the site after production in the factory.,So that that quality of each component is more guarantee,At the same time, the components are modular、After assembly,Installation only at customer site,Construction progress has been greatly accelerated.。

During the operation of the fixed crushing and screening production line,Dust pollution is mainly caused by crushing operation.、Screening operation、Transportation、Feeding, discharging and other links,Nanfang Road Machinery has abandoned the conventional scheme of on-site pipeline dust removal.,According to the site dust source of the crushing section、Actual parameters such as construction conditions,Dust removal nodes are set at the main dust raising points.,Greatly improve the dust control on site。It is worth mentioning that,When the customer does not carry out the production line outside the envelope,The overall production line has already met the local environmental protection requirements.。

02

High appearance、High quality stationary crushing line

Nanfang Road Machine with High Appearance、First appearance of high quality fixed crushing production line in Anhui,It has aroused widespread concern in the industry.!Many colleagues from the industry in Anhui have come to visit.,They praised Ajiu's forward-looking environmental protection thinking in the overall production line construction.,It can be said,An environmentally friendly and efficient one was built on the spot.、Intelligently produced“A division of steel”。

According to Liu Zhangmin, general manager of Anhui Yajiu Environmental Protection Building Materials Co., Ltd.:“Anhui Yajiu has maintained close cooperation with Nanfang Road Machinery since 2018.,The two sides have built a comprehensive、Multi-level、Cooperation and exchanges in various forms。”

General Manager Liu then introduced“We use all kinds of equipment of Nanfang Road Machinery for a long time.,A lot of equipment is used.,Completely exceeded our initial expectations.,The effect is particularly good。Nanfang Road Machine Fixed Crushing Production Line Intelligent and Efficient,Adopt centralized dedusting,Helped us achieve cleaner production;With the support of intelligent control,The working environment of our staff has also been greatly improved.。”

In addition,Nanfang Road Machinery also fully considers the needs of Anhui Yajiu.,Installation of equipment、Commissioning phase,The service engineer of Nanfang Road Locomotive is stationed for a long time.,Serve customers with heart,Contact to solve the problem immediately,And through training and other means,It effectively improves the technical level of field operators.。

03

Whole production process of fixed crushing and screening equipment

Anhui Yajiu uses purchased raw materials,Transport to the feeder via the loader,Carry out pre-screening through a bar screen,Detach 0-75mmMaterial,Then enter the muck screen to 25mmThe following muck with high mud content is screened out,Delivered to the muck bin。75% after passing through the grate screenmmThe above materials enter the jaw Crusher,Carry out the first stage of crushing。

Material enters jaw Crusher,Squeezing the materials entering the crushing cavity、Press、Rub、Crush,So that that particle diameter of the material become 250mmFollowing,And enter a conical crushing raw material cache bin for crushing in that next stage.。

At the same time,Residue of muck sieving 25-75mmMaterial and Jaw Crusher Discharge Summary,The iron remover effectively separates the iron products in the iron remover.,And deliver that materials to a conical crus raw material buffer bin。

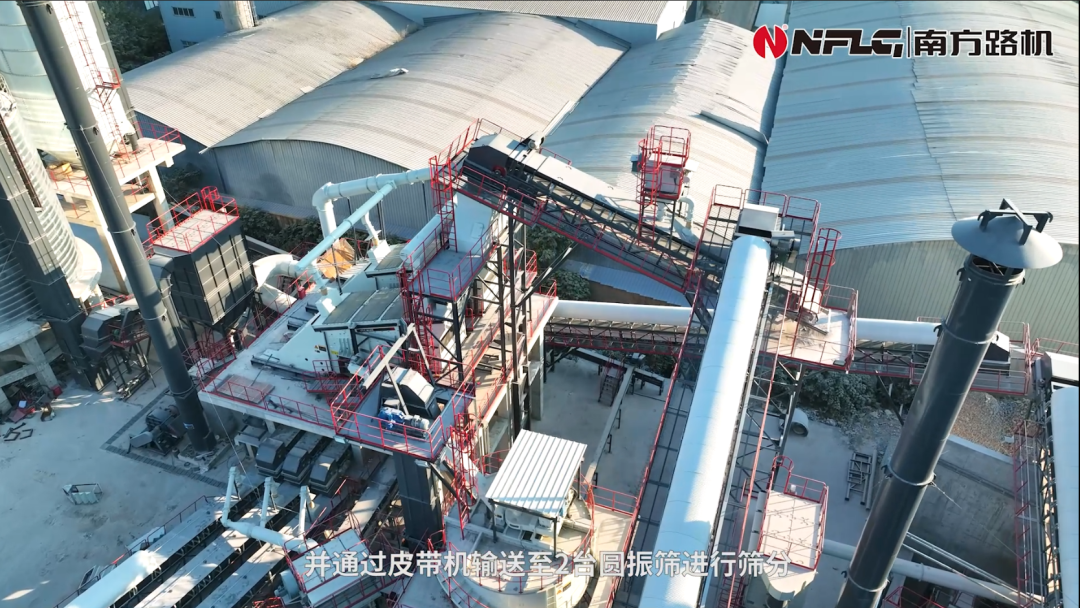

Then ,0 in the buffer bin of conical crushing raw material-250mmAfter the semi-finished material is treated by an iron remover,,Then the second stage crushing is carried out.:The multi-cylinder cone Crusher further crushes the material to 70mmFollowing,Conveyed by belt conveyor to 2 circular vibrating screens for screening。

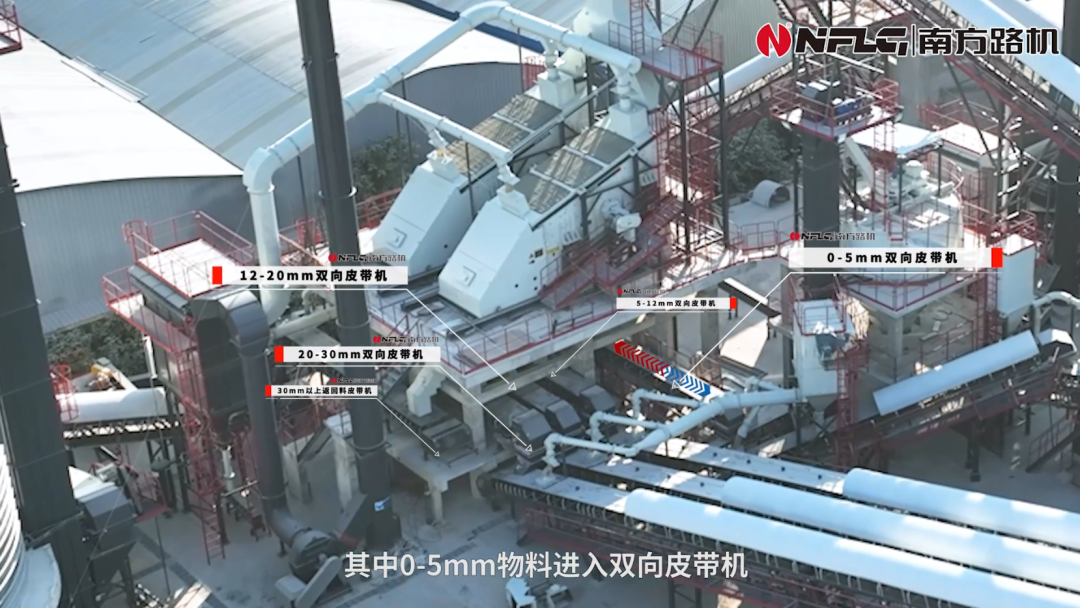

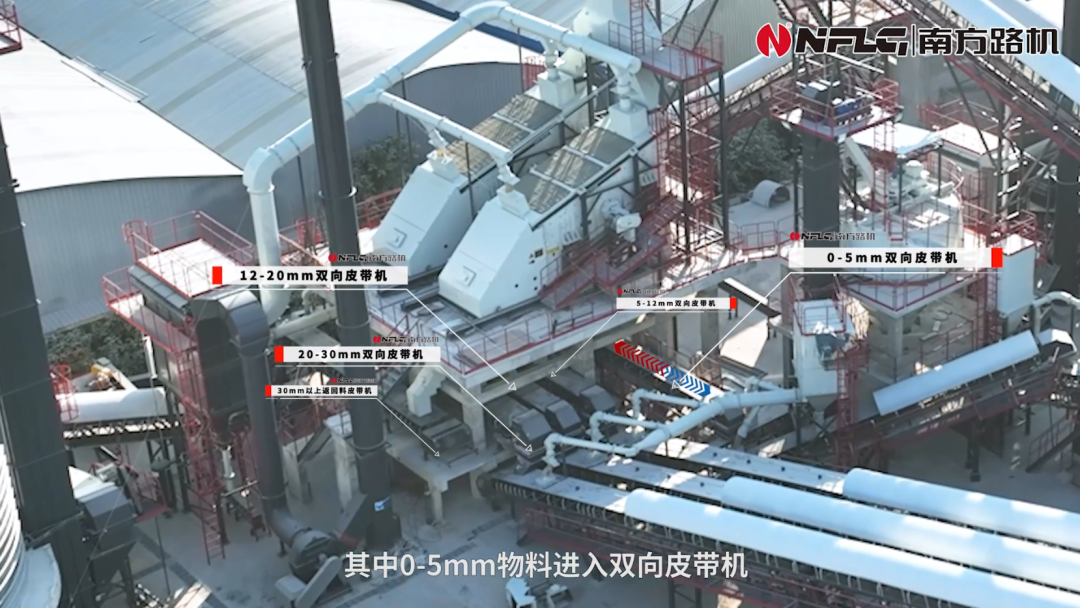

After the screening is completed,Finally, a total of 5 stoppers are delivered.,Respectively:0-5mm、5-12mm、12-20mm、20-30mm、30-70m。

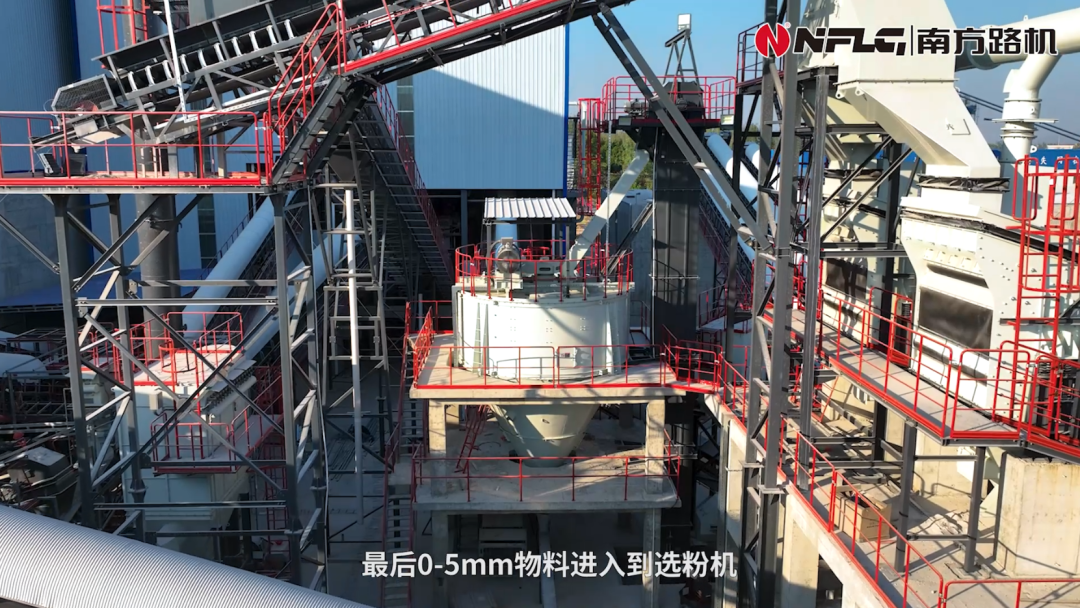

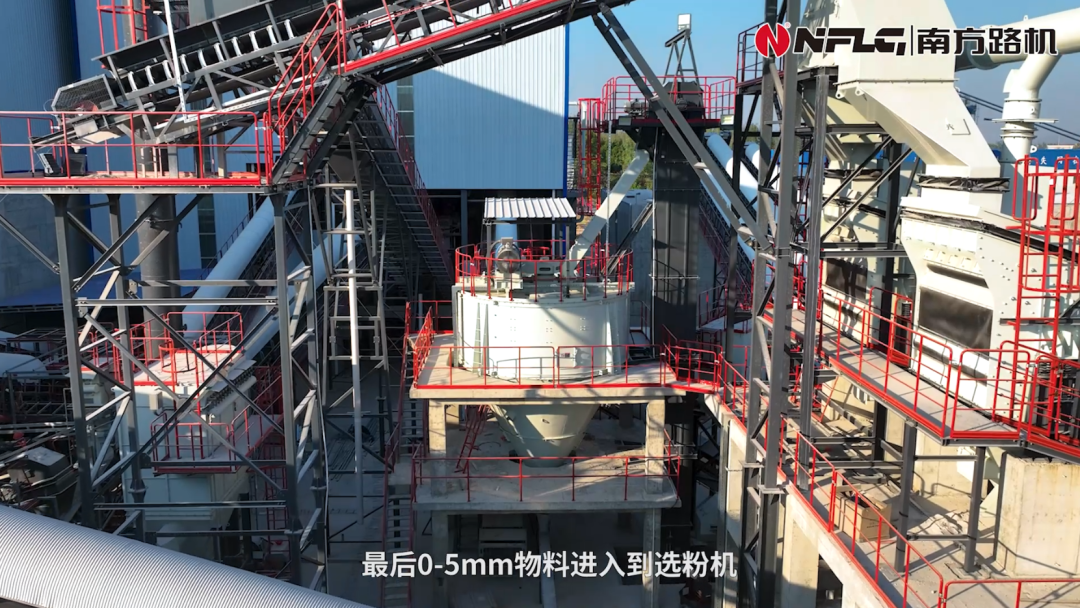

Where 0-5mmMaterials enter the two-way belt conveyor,Select to enterS3. Sand making is transferred to the raw material tank or to the two-way belt conveyor,The two-way belt conveyor can be selected to enter the powder concentrator or 1000tSand tank。

5-12mm、12-20mm、20-30mmThree-gear material enters the bidirectional belt conveyor,Select to enter the finished product silo orS3 Sand making transit raw material tank,30-70mmAnd that material re-enter the conical crushing raw material cache bin,Carry out cyclic crushing。

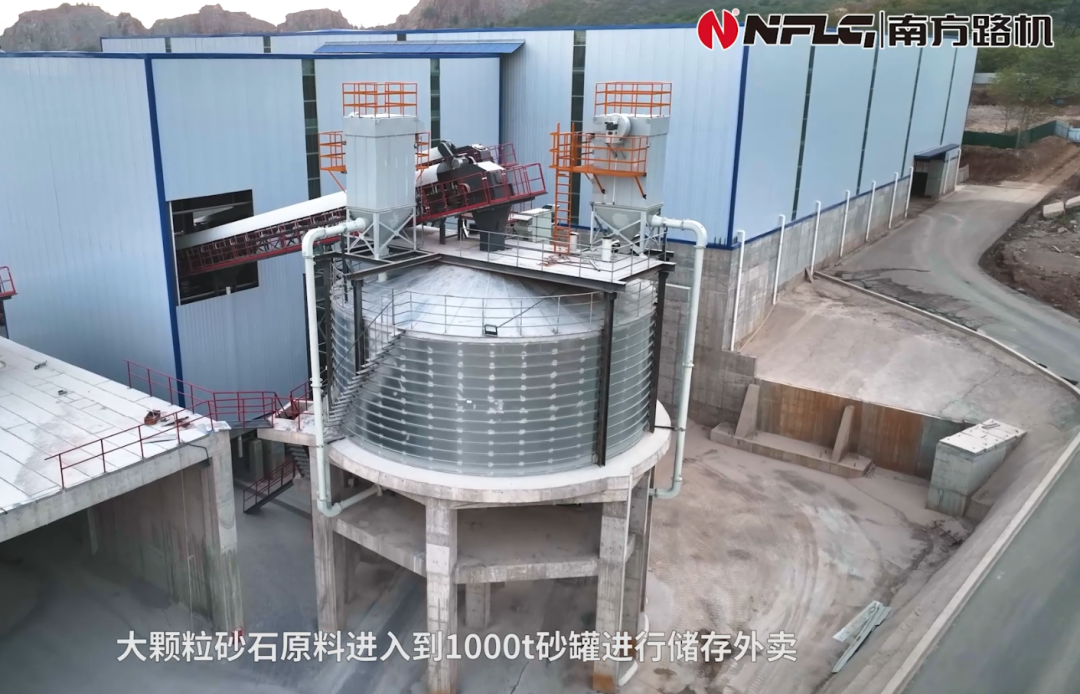

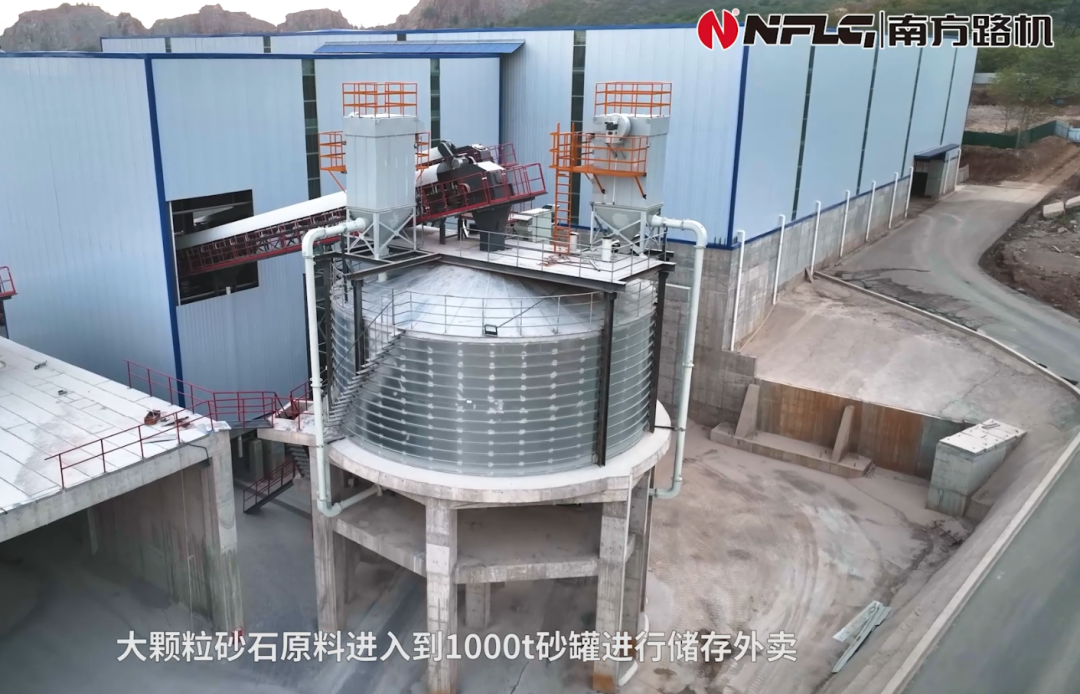

Finally,0-5mmThe material enters the powder concentrator.,And effectively remove 150% of that sandstone raw materialμmFine powder of the following,Large-particle sandstone raw material enters 1000tSand tank for storage and takeout,And 150μmThe following fine powder, together with the dust collected by the dust collector of the whole production line, is conveyed to 300 by the plate chain conveyortStone powder cans for storage and takeout。

Practice energy conservation and environmental protection,Build a green brand。Anhui YajiulvThe completion of the comprehensive industrial park of color building materials,It meets the needs of the green development of the market.,Helping to Sound Anhui's High-quality Transformation and Development“Assembly number”,It has injected strong impetus for enterprises to achieve high-quality development.!