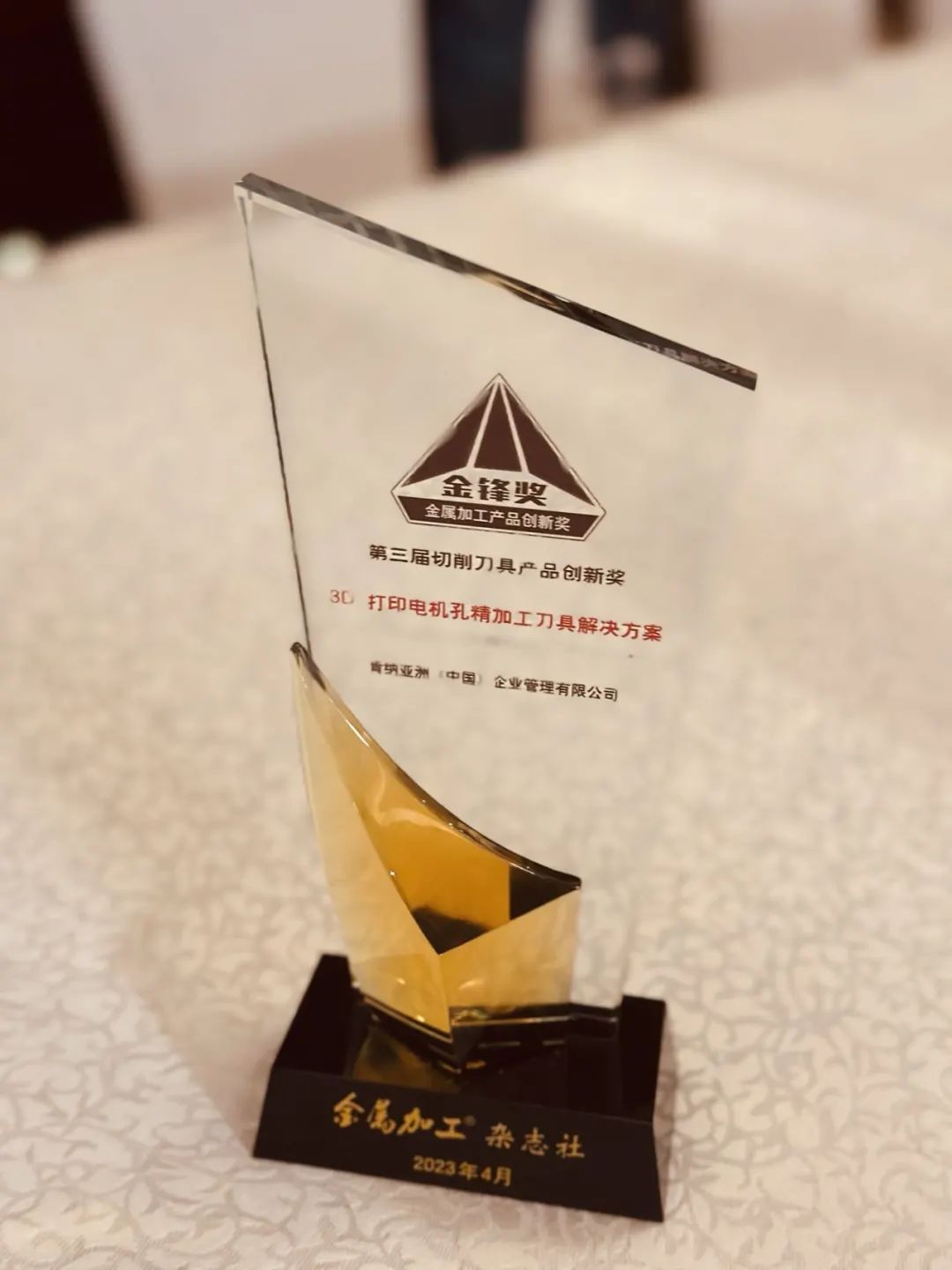

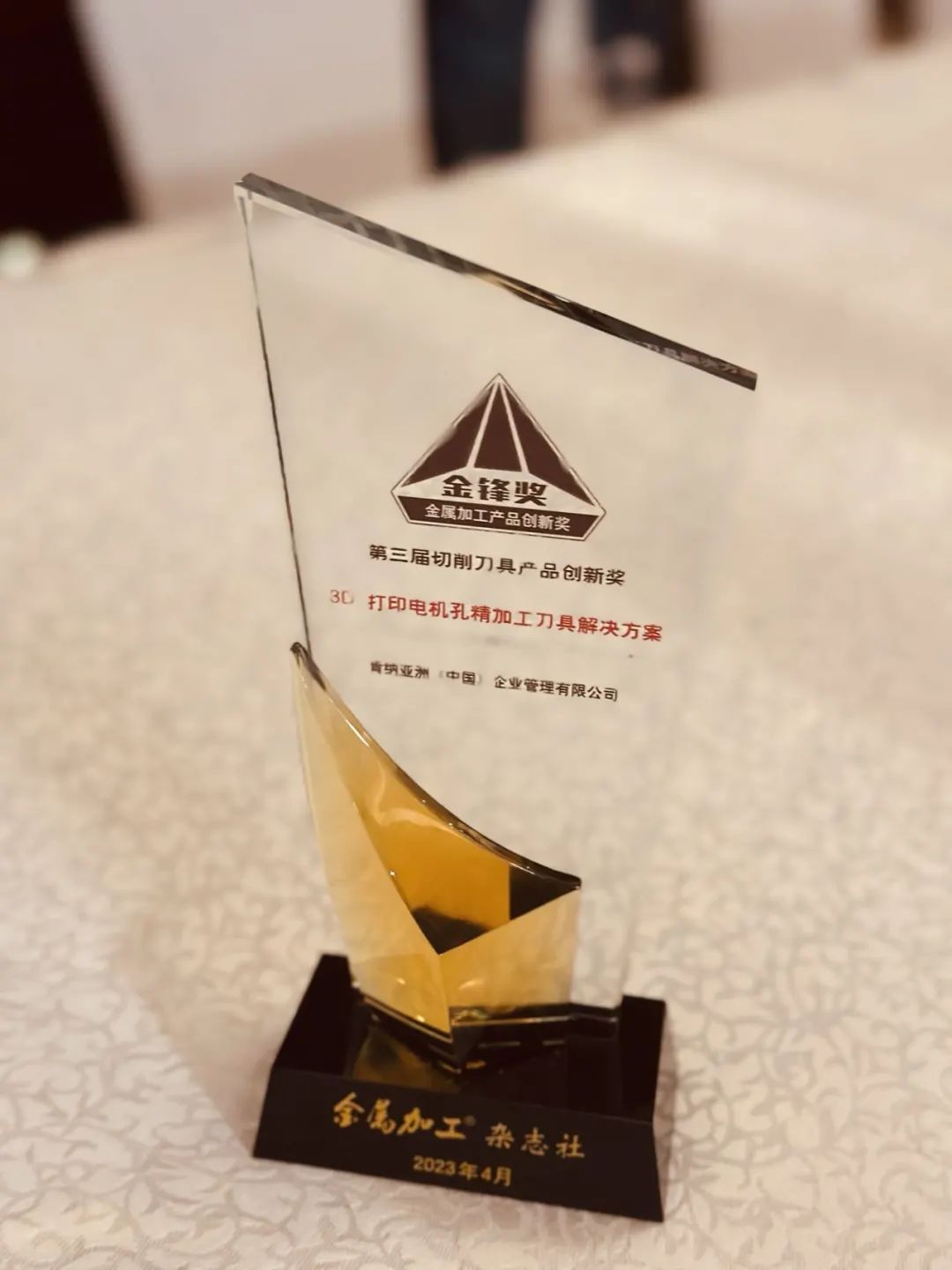

April 9,Release of the results of the 5th Cutting Tool User Survey sponsored by Metal Processing Magazine of China Machinery Industry Information Research Institute“Golden Front Award”The 3rd Cutting Tool Product Innovation Award Ceremony was held in Beijing Kuntai Hotel。

After more than two months of screening and strict data review.,Kennametal 3DPrinting Motor Hole Finishing Tool SolutionBreak through the tight encirclement smoothly,Won“Golden Front Award”The 3rd Cutting Tool Product Innovation Award。Kennametal also wonThe 5th Cutting Tool User Survey Customer Satisfaction Brands(Abroad)。

“Golden Front Award”The 3rd Cutting Tool Product Innovation Award was launched in February 2023.,After pre-screening、Publicity、Audit link,Sixty-three products from 40 domestic and foreign cutting tool enterprises have entered the network selection.、Expert review and editorial department review。Strict evaluation rules ensure the fairness of the awards to the maximum extent.、Impartiality、Professionalism and authority。Finally, the top 15 innovative cutting tool products at home and abroad with comprehensive scores were selected.。

Cutting Tool User Survey Sponsored by Metalworking Magazine。Based on the car、Aerospace、Mold、General Machinery、Screening of representative industry data such as rail transit、Statistics and analysis,Selected in 2023“Customer satisfaction brand”10 at home and abroad。

So

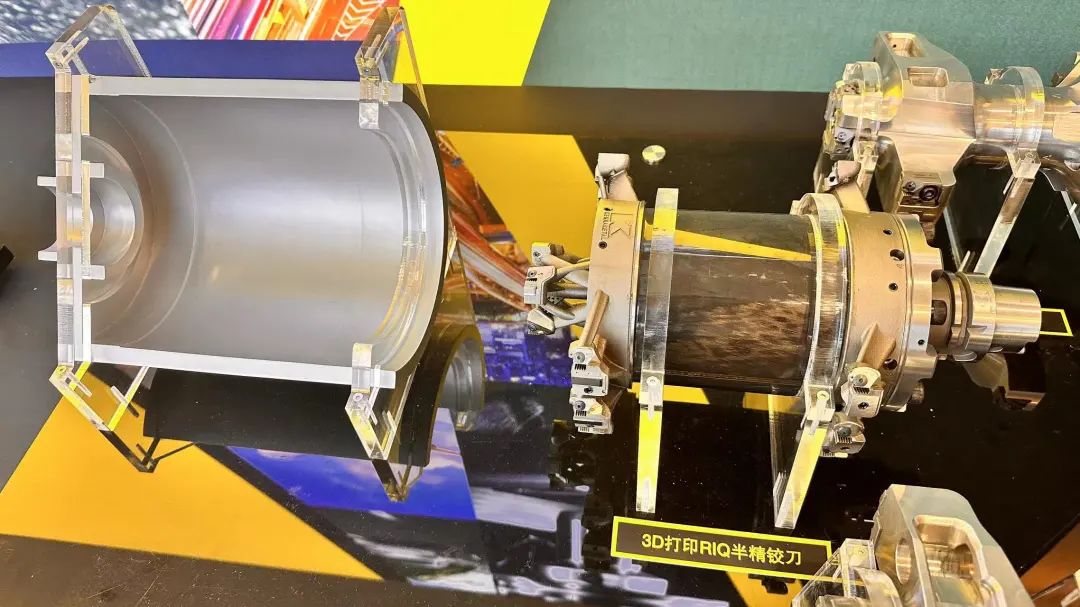

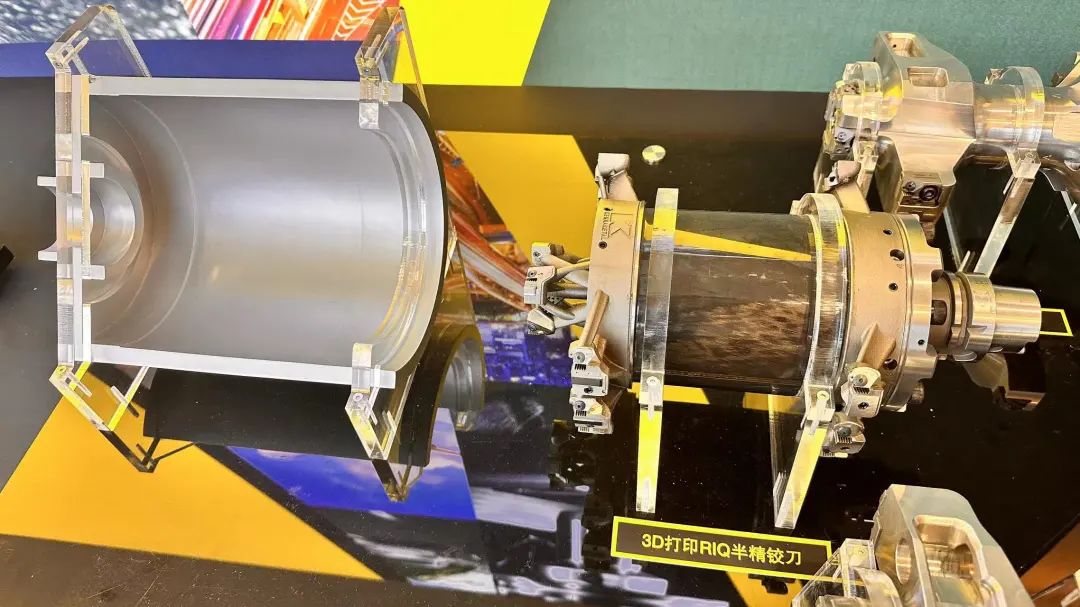

Kennametal 3DWhat does the printing tool look like??

How does it overcome the problem of motor hole processing??

Answer

Kennametal's innovative 3DPrinting motor hole finishing tool and carbon fiber tool body and mature technologyRIQA combination of blades,Excellent performance in motor housing deep hole machining applications,Boost productivity and reliability。

• The motor hole finish machining tool can simultaneously machine three sections of diameter sizes in one operation process.,And ensure excellent parallelism and concentricity of the machined surfaces,At the same time, it can significantly shorten the processing time.。

• Lightweight 3DPrint combination tools for faster tool changes,Excellent performance even on machines with low power torques。Meet surface dimensions and part tolerances without additional requirement。

• Wing-shaped arm design ensures smooth chip removal,Stacked internal cooling ensures precise coolant delivery to the cutting edge and guide bar,It also ensures a strong and efficient supply of coolant。

• KennametalRIQTool holder allows easy adjustment of machining diameter,New cutting inserts can also be set up easily。While improving the processing reliability, it can also save valuable tool adjustment time for customers.。

It is worth mentioning in particular that,This award is a continuation ofMultifunctional hardening alloy end milling cutterHARVI 1 TE, As well as set an astonishing record for the removal rate of titanium alloy metal.HARVI Ultra 8XKennametal later won the award for the third time.。