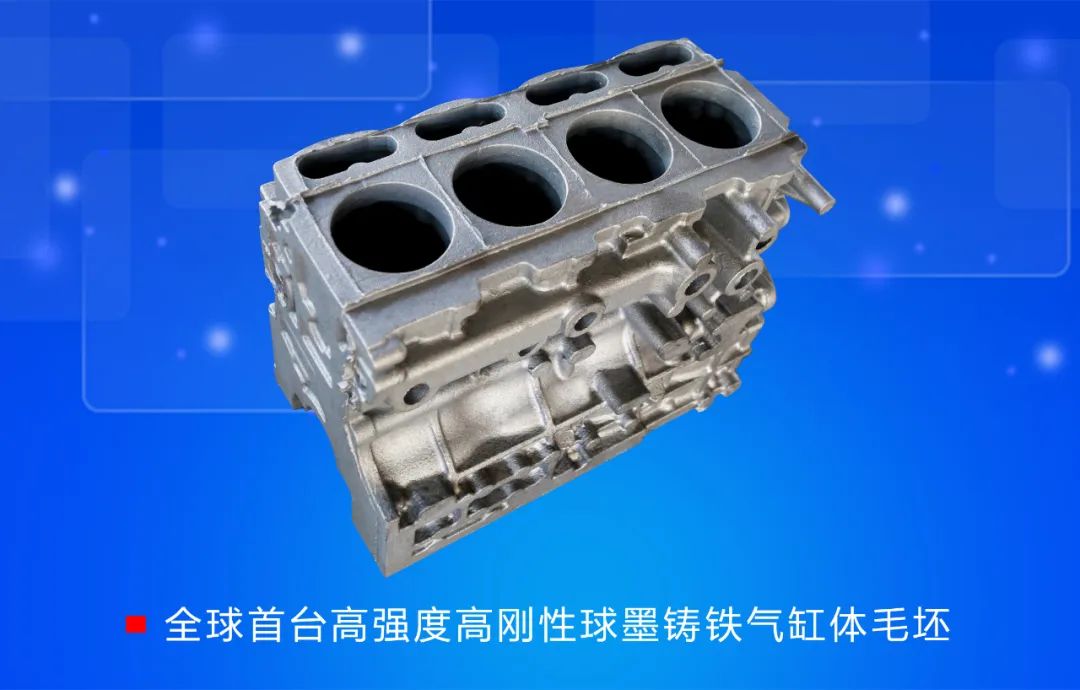

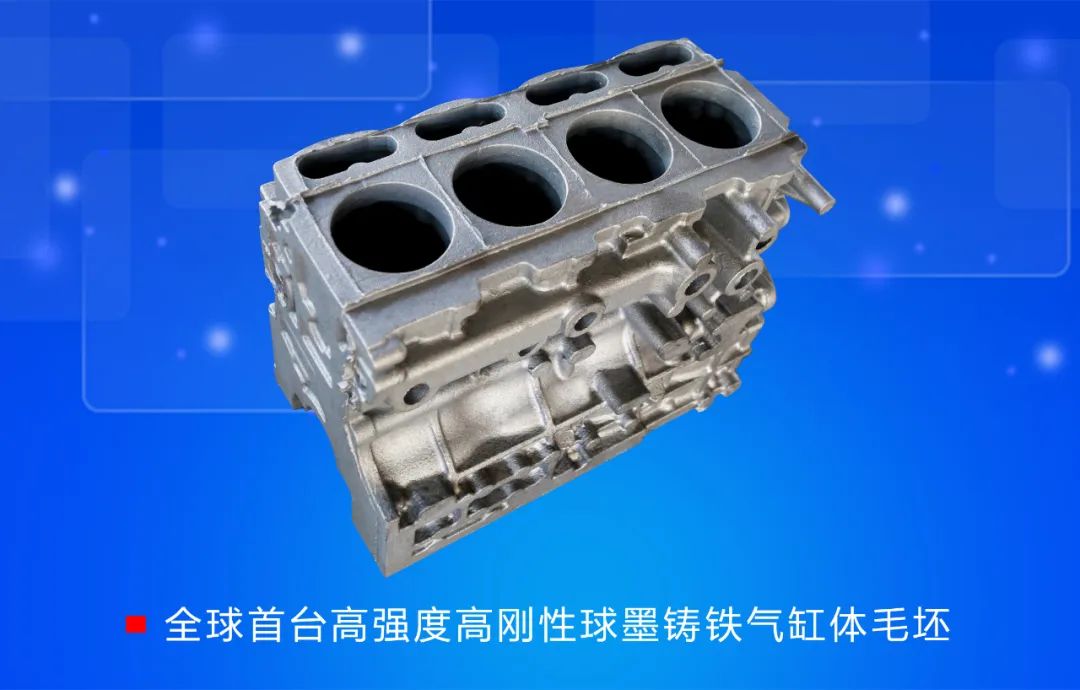

The world's first high strength and high rigidity ductile iron cylinder block was born in Yuchai

April 12, 2023

Recently,The world's first as-castQT900-The high strength and high rigidity ductile iron cylinder block was successfully poured in Guangxi Yuchai Casting Co., Ltd.,Surface quality of cylinder block blank、From the results of ontology anatomy and ontology performance test,All are superior to the original cylinder block,The weight is also reduced by 30 percent%。

The main difficulty in the production of ductile iron cylinder block is the complex structure of the parts.、Large difference in wall thickness。Because of that mushy solidification characteristic of ductile iron,,It is difficult to achieve feeding by conventional feeding proces,The cylinder block is very easy to produce a large number of shrinkage cavities and porosity problems.,It is difficult to solve the problem thoroughly with conventional technology.。

Yuchai Casting is based on the successful mass production of 3mm high-strength thin-walled flywheel shell instead of aluminum by using iron mold sand-coated process.,Cast state is adopted this timeQT900-2 Material and process,Gating system for original cylinder block、Many process parameters, such as the thickness of sand layer and iron mold and melting, were adjusted and optimized for the parts prone to shrinkage porosity.,It was a complete success。At present, this process material has been applied to the flywheel housing.、Crankshaft、Bearing cover、Robot reducer equiaxial、Shell casting products,Good results have been achieved.。

At present, the material of commercial diesel engine cylinder block is developing towards vermicular iron material.,But vermicular iron has low yield strength.、The performance of different vermicularity varies greatly.、It is easy to produce stress and needs structural strength to ensure the characteristics.,There are many difficulties in realizing lightweight with vermicular iron.。

And that yield strength ratio of the high-strength and high-rigidity nodular cast ironRUT400 increased by 114%、Modulus of elasticity increased by 13%,It is a new lightweight material for cylinder block.。It is estimated that,If applied to the heaviest block of the engine,It is expected to lose 100 kilograms.,At the same time, it is very easy to upgrade the engine and enlarge the cylinder.,And a gas engine can be avoid.、Cylinder Cracking Caused by Hydrogen Engine Knock,After the application of Yuchai's engine with a displacement of more than 11 liters, it will be able to better help customers realize commercial value.,It has great economic and social benefits.。