Help Napahai Flood Control Tunnel Project! China Railway Shanhe's First Open TBM Rolls off the Production Line

March 02, 2023

February twenty seventh,China Railway Shanhe's first open typeTBMSuccessfully offline in Sichuan Deyang Manufacturing Base,It will be sent to the Napahai Flood Control and Regulation Tunnel Project Site of China Railway No.5 Engineering Group Co., Ltd.。So is this“Diversion of water from central Yunnan”After the project,China Railway Shanhe Enters the Southwest Market Again。

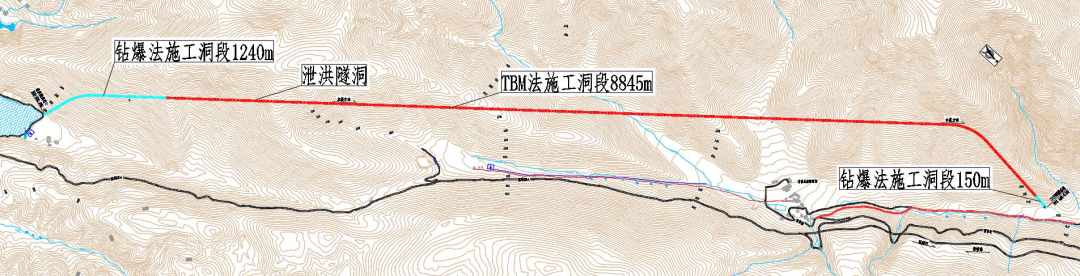

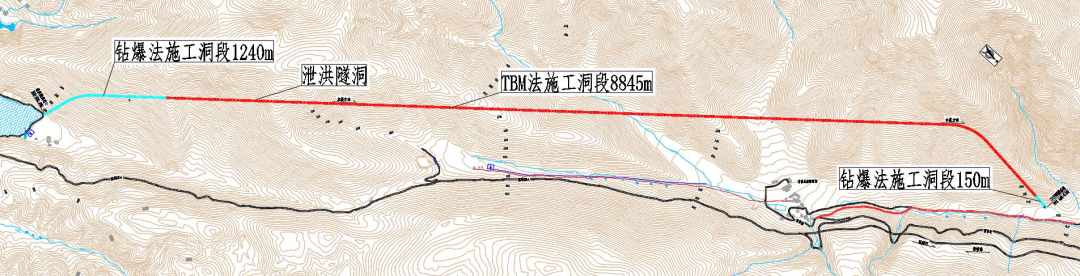

Napahai Flood Control Tunnel Project is located in the northwest of Jiantang Town, Shangri-La City, Diqing Tibetan Autonomous Prefecture, Yunnan Province.,The main task is to protect the villages around the Napahai Lake.、Farmland、The road around the lake、Shangri-La City、Flood control safety of Diqing Shangri-La Airport and ecological environment and landscape of Napahai Wetland。The project is from the intake section、Flood discharge tunnel、Regulating pool and spillway box culvert,It is a key water conservancy project in Yunnan Province.。

According to introduction,The tunnel of the project is 10 meters long.235 kilometers,In whichTBMThe construction interval mileage of the construction method is 9325m,Have a high altitude、Rock burst、Karst and mud inrush、Fault fracture zone and other key and difficult engineering points,Its geological conditions are mainly limestone.、Dolomite,Rock strength up to 60 MPa。

In view of the project situation,China Railway Shanhe has developed and produced special equipment for tunnel construction.TBM(China Railway Shanhe No.063)。It has an excavation diameter of 4.64 meters,The length of the whole machine is about 285 meters.,The main drive is driven by four groups of 350 kW variable frequency motors.,Maximum thrust up to kN 15877.,Weight about 1000 tons。

“Cutterhead diameter 4640 mm,Wear resistant design with cemented carbide,Positive hob spacing 89 mm、80 mm、75 mm,The cutter head has strong rock breaking capacity;Propulsion support system,The main beam structure is adopted、Cross pin floating support,Fast and flexible,Direction can be adjusted during tunneling,It ensures the safety and stability of long-distance tunneling of the equipment.。”Introduction of relevant R & D personnel。

In the process of research and development,China Railway Shanhe United Brother Unit gathers various technical elites to form a professional R & D team.,In the epidemic、Materials and other difficulties.,Carefully organize and coordinate,Considering the actual construction conditions of Napahai Tunnel,Docking with customer units for many times,Work overtime,Finally, it took more than six months to complete.TBMDesign and manufacture,It provides a strong guarantee for the smooth progress of Napahai project construction.。After the successful offline.,ThisTBMInstallation and commissioning will be completed in Napahai Project on March 31.,Launched on April 1。