Mention“Cobalt”This metal,A lot of people “Have a love-hate relationship”。 “Cobalt”High hardness、Heat-resistant、Wear resistant,Be known as“Industrial teeth”,It is necessary for the production of rock drill bits.,It is also a new energy Vehicle battery and aviation.、Space Flight、Armament、An indispensable player in the production of medical devices。

However,“Cobalt”Very scarce,It has certain toxicity.,Purification is more difficult,So the price is high.,Supply is in short supply,And unstable。Many enterprises have to endure for a long time.“Cobalt Granny”Harsh“Obscene power”。In order to change this situation,,An innovative research team from Sandvik decided to launch a “Cobalt-free coup”。

1

Cobalt is increasingly scarce,It is imperative to find alternative materials.

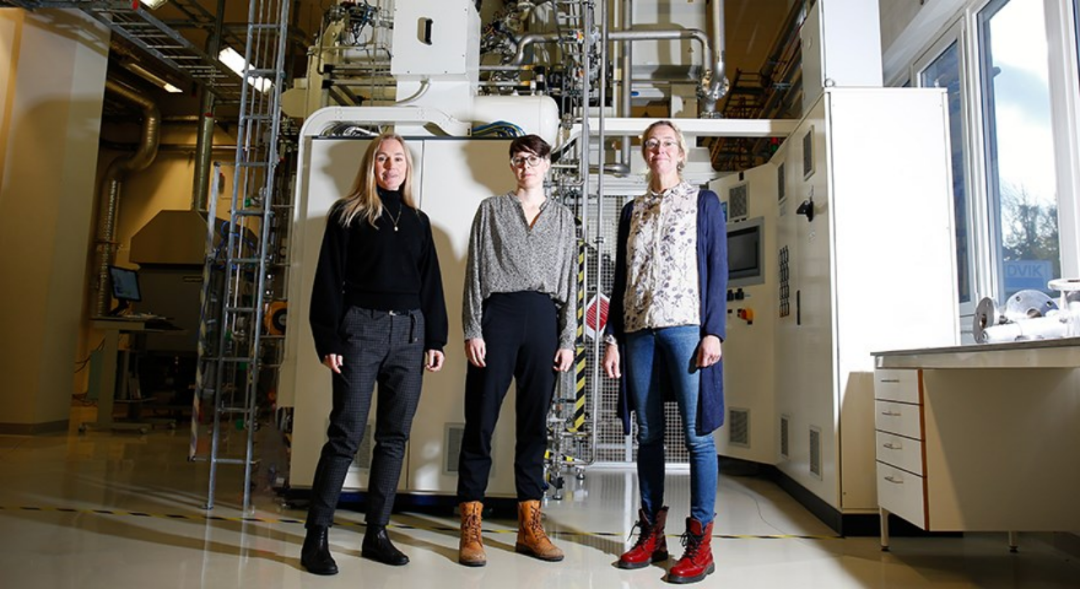

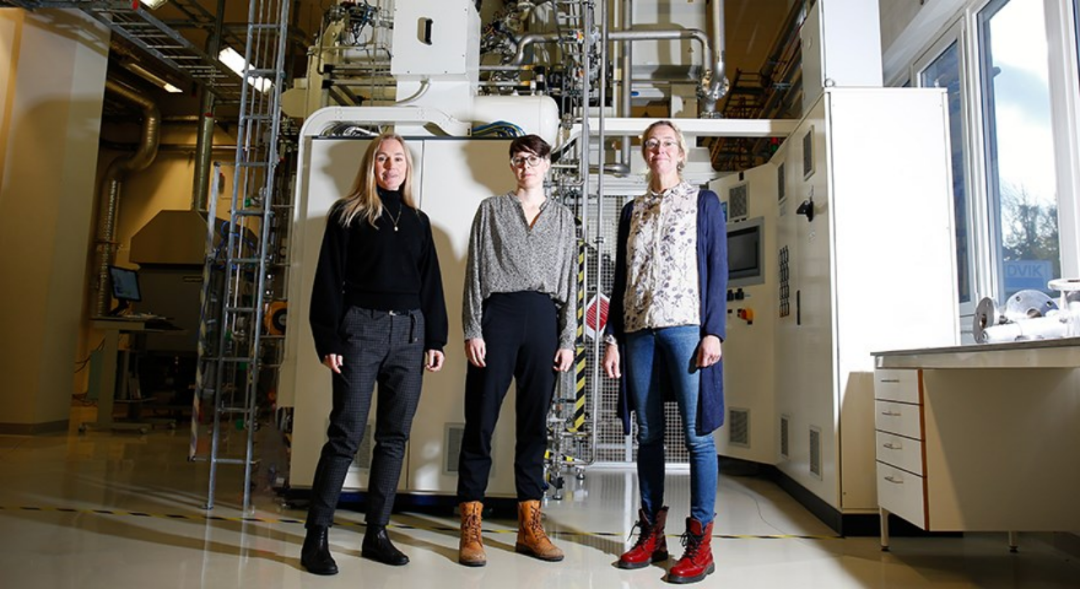

Innovation is Sandvik's DNA., The whole group has about 2,600 employees conduct research in 50 R & D centers around the world。Two of these researchers,Materials expertIda BorghAnd Sandvik Group expertsSusanne NorgrenNamely“Cobalt-free coup”The initiator of。

Over the years,They and others in the industry have been trying to find a solution.,To replace or reduce the use of cobalt in the company's rock drill bits.。At present, the team has obtained funds.,Used to study whether cobalt in rock drill bits can be replaced with high-strength steel。

Rock drill bits are available in various sizes,Smaller drill bit,Looks like a crown with six spherical blades.。Since 1945,Sandvik has been producing cemented carbide inserts for rock drilling.。On this blade,Hard tungsten carbide mix with cobalt is used,Cobalt is like an adhesive.,It forms an extremely hard composite with tungsten.,Which can drill through rock at incredible speeds.。

“We want to study how to replace cobalt with high-strength steel.,Is it possible to achieve similar performance。”BorghSay。In recent years,As global sales of new energy Vehicles soar,Demand for cobalt from electric Vehicle companies continues to surge。Cobalt prices are rising all the way,And there are often large fluctuations.,And,In the long run,Cobalt also has the risk of resource depletion.。So,BorghIt is considered that the time is ripe to apply for project research funds.。

2

Together with the Royal Institute of Technology andBoliden Minerals

Conduct research

Through unremitting efforts,Not long ago,This team has officially set foot on“Cobalt-free coup”The road。They're withKTHRoyal Institute of Technology、Multinational mining and metals companies of SwedenBoliden MineralsCooperation,Approved by the Swedish National Innovation Agency,Successfully applied for a research project costing SEK 7 million,For three years。

Susanne Norgren

“We are very proud to be able to obtain funding and cooperate withKTHCooperation,This means that we can accelerate research with the help of the college and the modeling methods they have recently developed.。”NorgrenSay。“In addition,We are further researching and designing alternative materials.,At the same time,Let the end customerBolidenParticipation in the project is also crucial。”

Ida Borgh

“This method is unique.,And at the forefront。”BorghTalk about:“Application knowledge and material support from industry partners,We will move forward with this research more quickly.。Sandvik Mine and Rock Solutions will recommend material based modeling,Manufacture of new cemented carbide material。We will be in a laboratory designed for rock drilling applications.,Testing and analysis of new materials。The new drill bit will also beBolidenTo test a mine.。That means that in this project,,It covers the whole value chain from drill bit research and development to production and application.。”

Annika Kaar

This research project has received strong support from within Sandvik.。Carbide R & D ManagerAnnika KaarPoint out,The project is also an important part of the company's sustainability efforts.。“Sandvik has reduced its demand for cobalt by recycling used drill bits., If this research project is successful,,It will pave the way for future cobalt-free drill bits.。From the perspective of sustainable development,This will have a positive impact.,And will reduce vulnerabilities in the supply chain。”Annika KaarSaid excitedly。

This is an unprecedented study.,Despite the enormous challenges,But researchers remain optimistic.。BorghSay:“We hope to use special methods to improve the properties of steel.,As difficult as it is.,No one has done this before.,But we are confident。”The project has officially started in October 2022.。KaarSay expectantly:This is an exciting innovation.,We will conduct field tests in 2025.,We hope it will be a great success.!”。