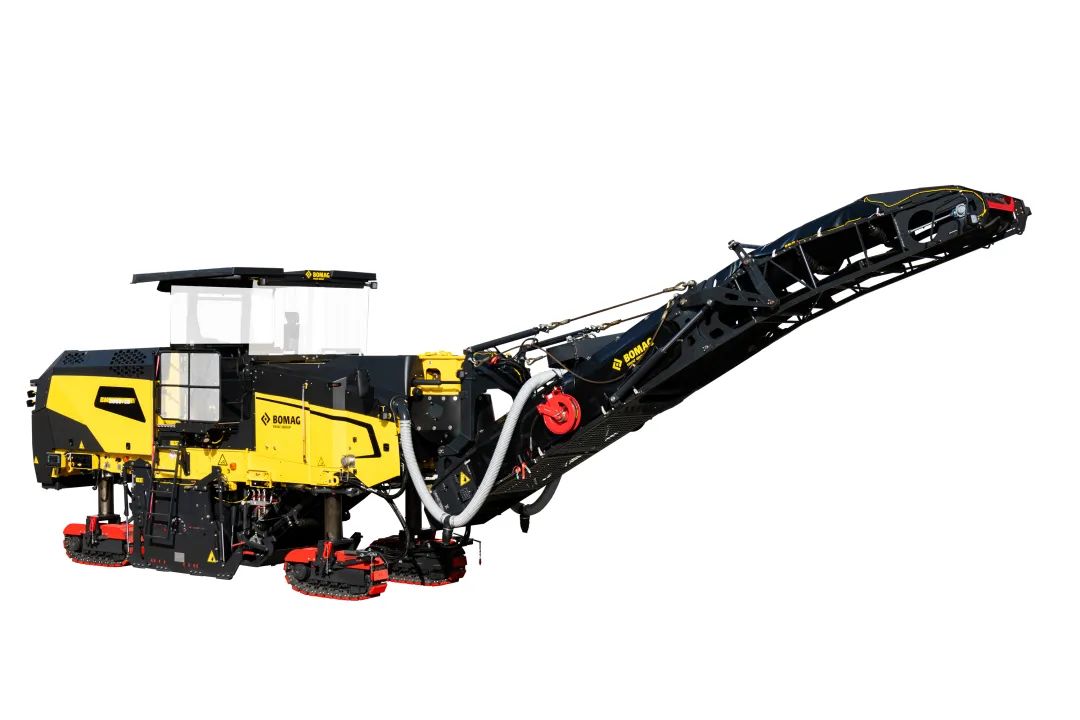

- BM2000/58&68 Cold Milling Machine -

BM2000/58&68

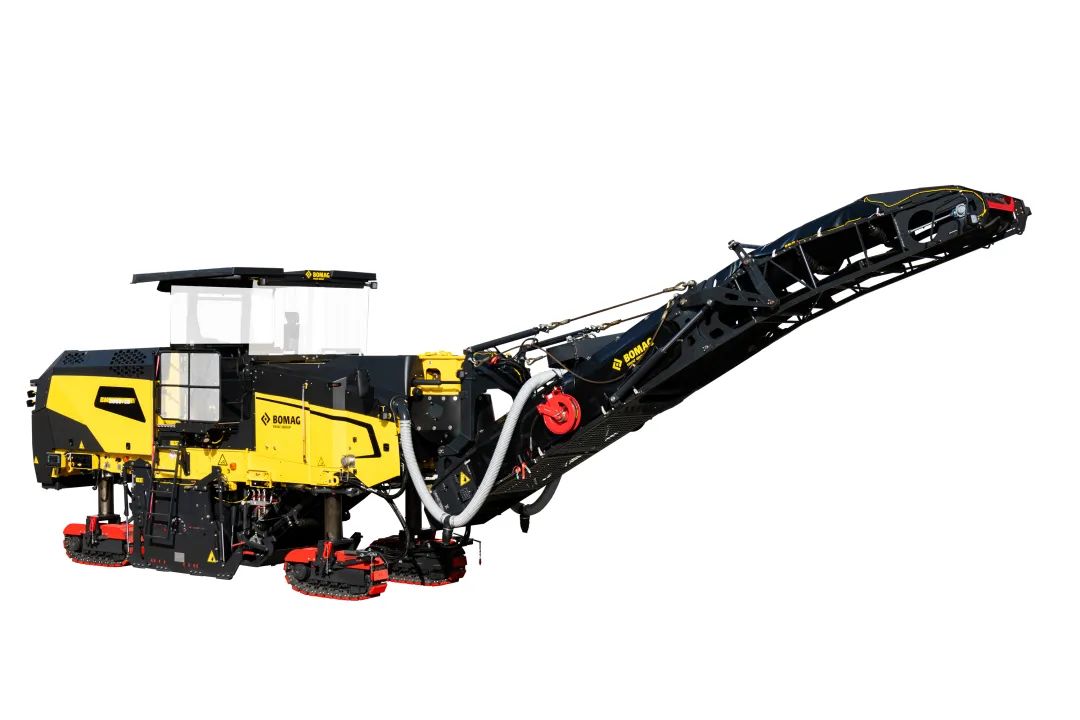

Advanced milling technology、Powerful milling capability、A high degree of adaptability、A wide range of uses has always been the label of BMW Milling Machine.。In order to better meet the expectations of users for BMG Milling Machine,At the same time, it is also to meet the fourth emission standard of non-road countries.,Baomag has launched two new 2-meter milling machines for Chinese users:BM2000/58 andBM2000/68

,Duration 05:24

Made in China of German descent

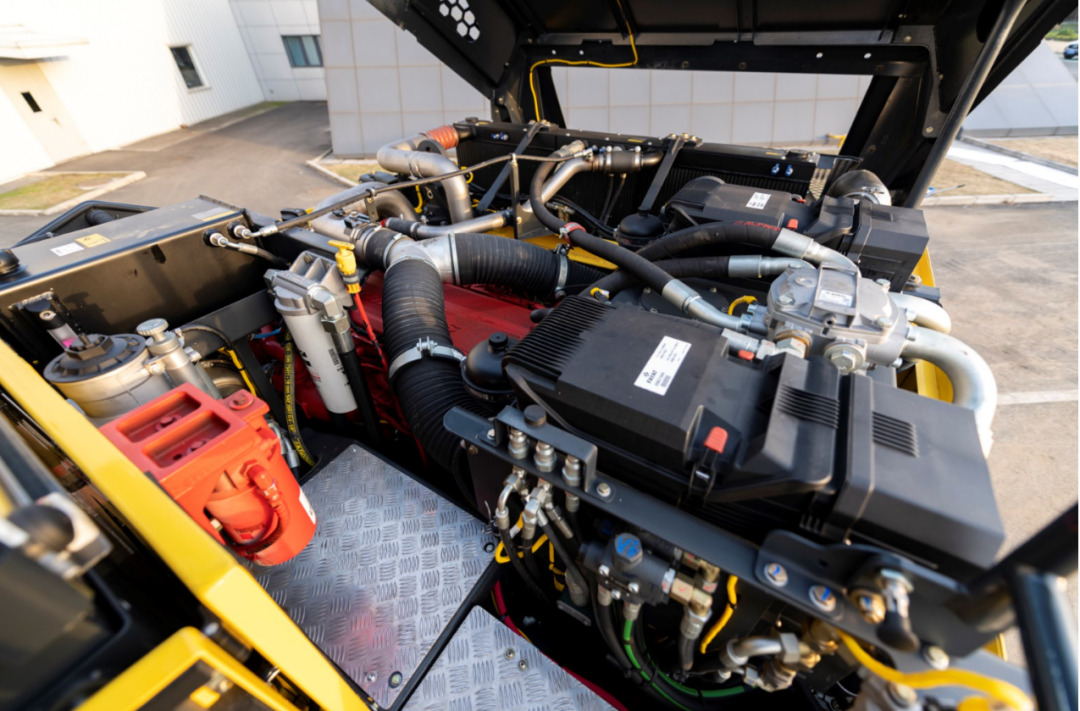

These two milling machines are equipped with imported Cummins.X15 Engine,Rated power 447/470 kW,It has laid the foundation for its strong working ability.(Maximum milling depth 350mm),At the same time, it meets the fourth emission standard of non-road countries.,Whether from the milling performance of the machine or the maintenance of the machine,It has continued the consistent style of BMW products for more than 60 years.:Reliable、Durable、Efficient。BaomagBM 2000/58&Introduction of Milling Machine 68,Set up a new standard for the 2-meter milling machine industry in the Chinese market.。

The most compact products of the same level/Flexible

BMW's new milling machine can be very flexible even if it is big.

BM2000/58/68

BM2000/58&68 has the smallest milling radius in the same level of products of all brands,Cooperate±65°Rotation angle of conveying belt,Even on a narrow construction site.,It can also complete the milling task quickly and neatly.。At the same time,BM2000/58&68CEIt weighs only 27 tons.,Length≤11.75 meters,When the machine is to be transferred for transportation,Less weight gives you more efficient transportation and greater economic savings,At the same time, it can flexibly increase the counterweight according to the needs of customers to meet the needs of different construction sites.。

The compact machine also creates the best view for the operator.,And fewer work blind spots.,After selecting multiple cameras, the operator can better observe the dead angle of the field of vision.,Easily observe the state of the machine and its surroundings,Work is more comfortable,O as to obtain the best construction effect.。

Rear camera

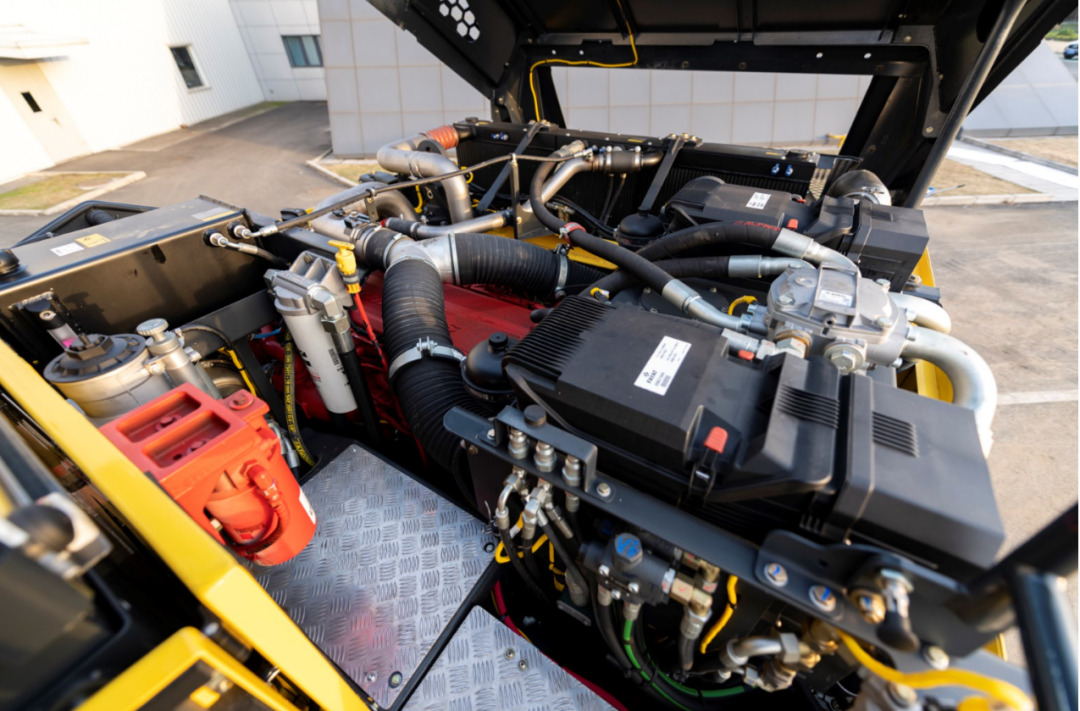

Extremely convenient maintenance

The channel on the bridge is in direct contact with the filter elements of the engine and hydraulic system.,Routine maintenance points are within reach。The filling port for the diesel fuel and exhaust treatment fluid is located on the right side of the storage compartment.,Easy raise,No need to fill from the side of the machine or through the engine compartment。

Tailgate opening and closing hydraulic control

It is worth mentioning that,BM2000/58&All 68 support the optional Kubota standby engine。Realize the most advanced dual-engine configuration in the world。

When the main engine is switched off,All hydraulic functions can be operated from the standby engine。This not only facilitates the replacement of the cutter head,It is also conducive to daily cleaning and other work.。It can also be used as an emergency drive mode.,When the main engine fails,The machine can also be driven effortlessly out of hazardous areas and construction sites,As in a tunnel or airport project,The auxiliary drive system greatly reduces the risk of high fines.,At the same time, it also saves the cost of the crane.。The small engine configuration also greatly reduces fuel consumption.,Achieve the best energy-saving effect。

Kubota auxiliary drive system

Baomag leveling system

BM2000/58&68 is equipped with two 7-inch full-color displays to read data of various working conditions intuitively,It is also equipped with BMW Quick Selection System.、BMG Easy Milling System and BMG Easy Leveling System,Further simplify the operation process。Any operator can operate skillfully as long as he has received simple training.BM2000/58&68 Milling machine。

7-inch full-color display

The BMG leveling system also supports automatic storage of leveling data.,One-key operation for directly calling out the stored data,At the same time, it is equipped with soft start、One key through the manhole cover,As well as a variety of leveling system options.。With the intelligent leveling of BMW、Milling assistant,Any mobile phone operator can run smoothly.,Accomplish the construction task with ease。

BM2000/58/68 Ground Control Console

BMG milling technology

BM2000/58&The milling drum of the 68 has the best uniform tool distribution,This ensures the best milling quality and efficiency of the BMG milling machine,And minimize operational wear and tear。

Optimal tool distribution

The edge area of the outer ring of the milling drum is an area that receives particularly severe wear in everyday work,BMG's new milling machine has a special wear-resistant treatment on the edge of the milling drum.,Ffective additional protection of the milling drum。

Crescent-shaped wear-resistant edge plate

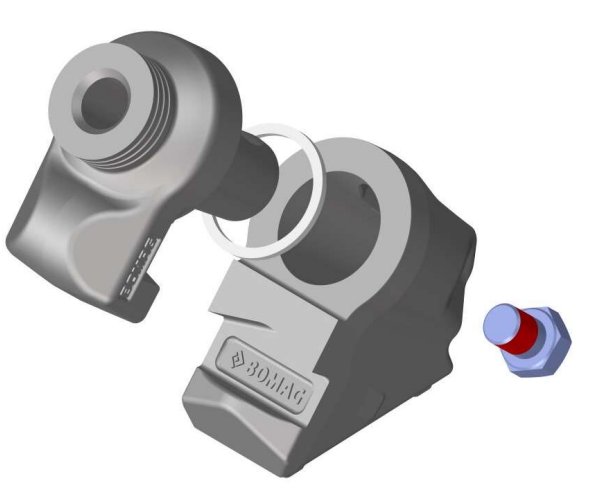

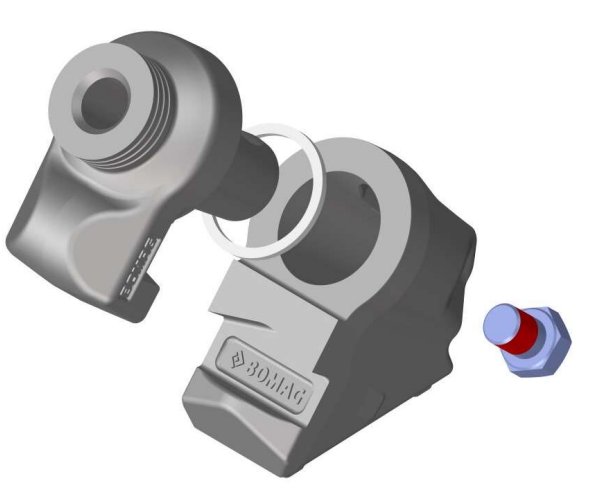

BaomagBMS15LThe cutterbed system is one of the keys to the success of the BMG milling machine,It not only has high milling efficiency,、And that service life is long,It is also recognized by users for its convenience of operation and low maintenance cost.。Tool apron bolt tensioning torque only 100Nm,The cutter head is easy to knock out from behind.,As a result, the time to replace the cutterbed is reduced by half.,It can save you more economic and time costs.。