We meet again.!

Are you still worried about changing the drill rod frequently??

Don't worry!

Shandong LingongNewA generationHigh wear resistant drill rod

Better qualityTSG46AMaterial

Great value for money

Escort your way to wealth!

Come and have a look.。

Q1

What is a drill rod??

Hydraulic breaking hammer——Drill Rod,Is installed inHydraulic breaking hammerA special accessory on the.。Utilize the impact energy generated by the breaking hammer piston,The impact energy is transferred to the object to be crushed by knocking the drill rod,Cracking and breaking it。The drill rod belongs toMedium of energy transmission,When working, it is subjected to the impact force of the piston and the reaction force of the crushed object.,As well as various physical forces generated during operation.。Therefore, the drill rod belongs toWearing parts、Consumables。

Q2

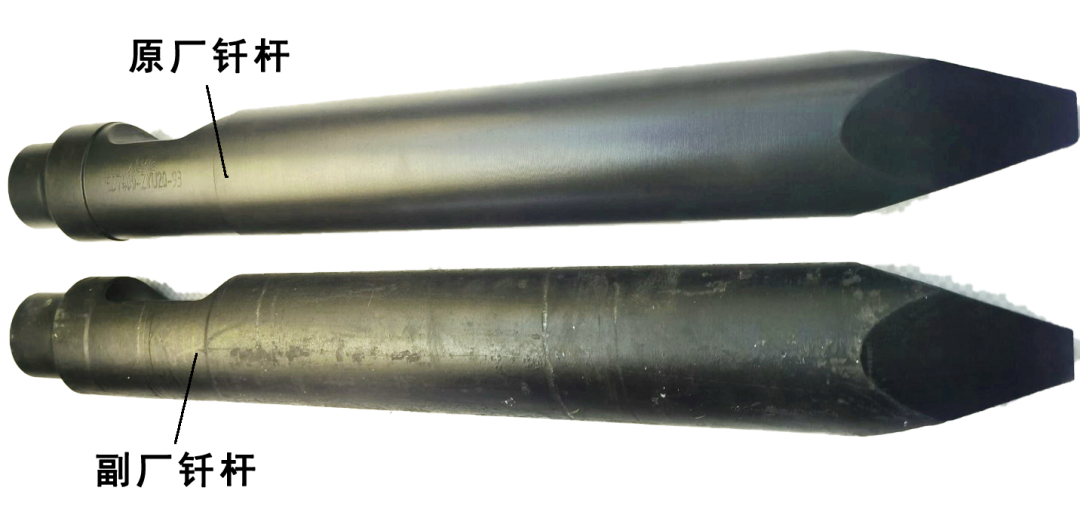

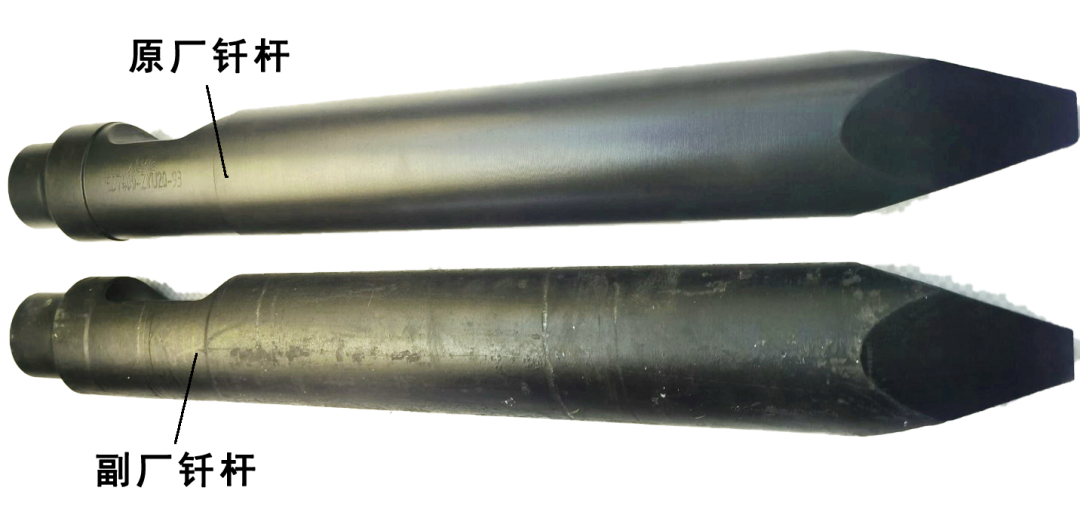

Is there any difference between Shandong Lingong high wear-resistant drill rod??

1

Great value for money&Good market feedback

Ultra-wear-resistant, low failure rate and long service life,CanReduce downtime for maintenance。Stable and reliable,Effective prevention of unplanned downtime;To a certain extentProtect the piston head,Prolong the service life of piston;Lower overall operating costs for customer,Improve the output rate,Reduce equipment risk。

Shandong Lingong High Wear-resistant Drill RodMarketGood performance on the Internet,It can be said that“True gold fears no fire.”。Good products only useFactTalk:

Used in a mining industry in JilinTSG46AMaterial 1.9m four-side forged drill rod(Tool Mounting Exposed Dimensions 123cm,Use 187hMeasuring Exposed Dimensions 74cm,Average 0.26CM/h;Fully used to exposed length 60cmTime(Change the size))Service hours up to 240hAbove

Used by a leasing company in GuangdongTSG46AMaterial: 2m conical grooving drill rod is being chiseledGraniteUnder working conditions,(Tool Installation Exposed Dimension 127cm,Use 162hMeasure the exposed dimension 90cm,Average 0.23CM/h;Fully used to exposed length 60cmTime(Change the size)),Service hours up to 290hAbove。

According to the customer's estimation, Shandong Lingong high wear-resistant drill rod is better than ordinary drill rod in the market.UseCostEvery hourSave about35%

2

Product material upgrade

MarketCommon42CrMoADrill Rod,The general use time is100~120Hours or so。The drill rod is usedTSG46AMaterial,It is a kind of special super wear-resistant material with high strength.,Life spanCan exceed 42CrMoA 50%~80%Above,StabilitySuper1 timesAbove。

3

Unique heat treatment technology

First from the deviceNumerical control vacuum high-pressure gas quenching furnace(In domestic drill rod manufacturing enterprises,The onlyAdopt new numerical control vacuum high pressure gas quenching furnace)Make the productHardnessMoreUniform、And that stability is good,No oxide scale on the surface,High surface finish。Uniform distribution of internal crystal structure,Strong impact resistance。

Adopt “Sectional Heat Treatment Technology” ——Raw material tempering、Normalizing,Quench、Tempering、Salt tail and other processes。Refine the internal structure of material,Eliminate internal stress,Make the product moreWear-resistant, stable and reliable。

4

Strict quality control&Careful surface treatment

Each batch of raw materials entering the factory shall be carried out comprehensively.Flaw detection,Strive to ensure raw materials 100%Qualified,The heat treated drill rods of each batch shall be fully processed.Secondary Flaw Detection、Metallographic structure analysisAndHardness test,To ensure the best performance of the product。

Surface each drill rod prior to paintingShot blasting,Eliminate product surface stains, etc.,Make the paint firmer,The product is more beautiful。

Primer plus finish is used for surface painting process.,Two coats of paintCraft,O that the surface of the product is smoother and more beautiful。

Q3

How should I choose temporary drill rod?

The difference of drill rod is mainly reflected in itsStructure and shape of pointed headGo,Therefore, we can choose the drill rod suitable for our working conditions according to these shapes.。Next, I will introduce some commonly used drill rods to you.。

1

Conical slotted type&Saw tip slotted type

Cone slotted and saw tip slotted types are generally used for large breaking hammers.φDrill rods above 140,After heat treatment, the grooved drill rod,The hardness of that core is increase,So that that wear resistance is bet。The notching of the tip is also more conducive to allowing the tip of the drill rod to be produced during striking.Gas and dust discharge,ReduceOf the drill rodStrike resistance,Make the drill rod moreIt is easy to cut into the breaking point。

Recommended use:This type of tool is suitable forMineMine,EspeciallyViscosity comparisonBigMine geology

2

Saw point type

Saw point tools are one of the most common types on the market,Generally used forMedium and small breaking hammersφDrill rods under 175,Have a strongPenetration,Its characteristic is to concentrate the force on one point to break.,In this way, a strong crushing force can be generated.,Break the surface with a point。

Recommended use:Applies toRoad works,Bridge engineering and variousHigh hardness rock、ConcreteWait,This kind of sharp drill rod is widely used in the whole country.。

3

Straight shovel type

The structure of the tip of the straight spade drill rod is simple.,The resistance is small,The crushed surface is relatively flat.。

Recommended use:Applicable to all kinds ofThe geology is softAndNeutral stratified rockCrushing or trenching operations,Concrete cutting,Tunneling, etc,This kind of tip drill rod is widely used abroad.。

4

Forged type

Forged with squares、Six directions、Octagonal type is commonly usedHeavy breaking hammerφDrill rods above 175。The tip is hydraulically forged,Increasing the core density,More effectively improve the wear resistance of the tip。

Recommended use:This tool is generally suitable forGranite,Iron ore,Black ore,Limestone and sand-bearing geologyUse。In China, like Beijing, Tianjin and Hebei,Anhui,Zhejiang,Widely used in Guangdong and other places。

5

Flat head type

There is no penetration for the flat head type tool,It's like a blunt instrument.,Good for large brittleness or single objectCrushing effect。

Recommended use:Generally used forSecondary crushing,Mostly used forStone factory。

6

Big-headed

Large head drill rod,CooperateSmall breaking hammerThe Excavator can enter the narrow construction site more flexibly.,Large crushing contact surface and high efficiency。

Recommended use:Mostly used forStreet building demolitionEngineering。

7

Pile driving type

The tip of the pile driving drill rod can be designed and customized according to the size and use of the pile.。It can enter the narrow construction site more flexibly with the small breaking hammer Excavator.。

Recommended use:Used for installation of road guard net,Cement pile、Iron stakeAnd some for water work.StakeEtc

Q4

How to buy temporary drill rod?

Lingong has dealers all over the country.,Recognize the regular channels of Shandong Lingong,Choose the right product to buy.!