Compared with the traditional milling and paving scheme,,Wittgen W 380 CR Low carbon and environmental protection of cold in-place recycling construction technology、It has outstanding advantages in construction efficiency and other aspects.。In recent years, it has been successfully applied in many pavement maintenance projects in China. W 380 CR Has very wide applicability and excellent application effect.。

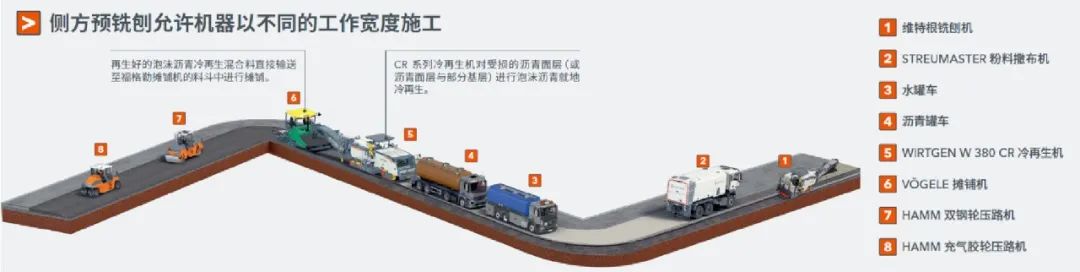

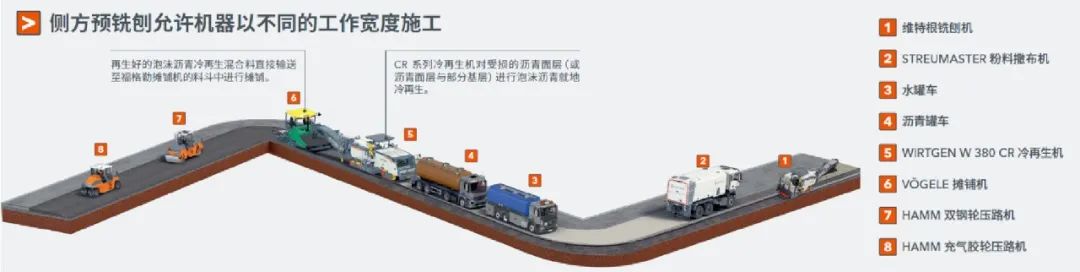

Based on synchronous paving W 380 CR Cold in-place regeneration proces,Basic regeneration width 3.8 m, Cooperative operation of multiple equipment,Diversified construction modes,The application is flexible and efficient。Except single-lane single-layer cement cold in-place recycling construction or single-layer foamed asphalt cold in-place recycling construction,It can also implement double-layer cold regeneration in place for the road sections with serious damage depth.,That is to say, the surface course is cold regenerated on the spot with foamed asphalt.,At the same time, the cold regeneration of cement in situ is carried out on the base course.,Achieve synchronous maintenance of two structure layer。

In addition,When the required regeneration width is greater than 3.8 m And less than 5.8 m Time,It can also be realized by side pre-milling. W 380 CR Cold recycling units are constructed in different working widths。Since mid-November 2022,Wittgen W 380 CR The cold regeneration unit is constructed in this mode.,Successively in Guigang City, GuangxiS204 Pavement Medium Repair Project and Yulin CitySThe successful application of 205 in asphalt pavement overhaul project。

S204 Pavement medium repair works

Project overview

This project belongs to the pavement maintenance project of ordinary national and provincial highways in Guangxi.,The starting point is near Ma Lian Township, Pingnan County, Guigang City.,The destination is near Fangtiantun.,Maintenance mileage 7.316 km。

This section is mainly cracked.、Blocky crack、Longitudinal crack、Transverse crack、Rutting and other pavement diseases,The medium repair project only reconstructed the original pavement structure layer and ancillary facilities.,To improve road capacity,Improve the traffic appearance of villages and towns along the line,And to better serve the residents along the line.。

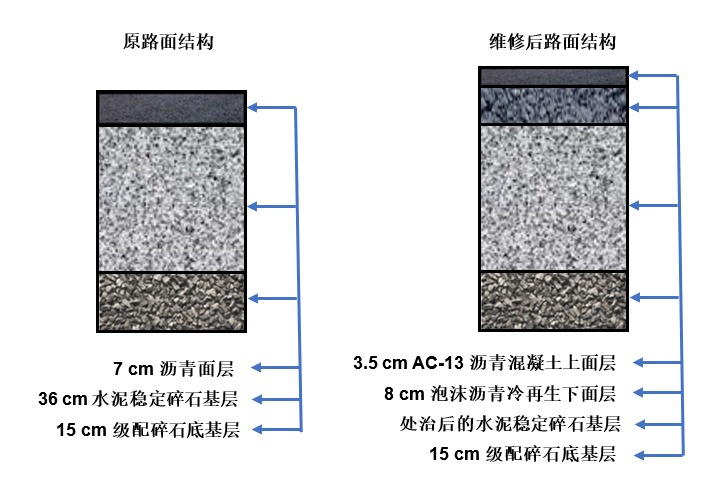

Application scheme

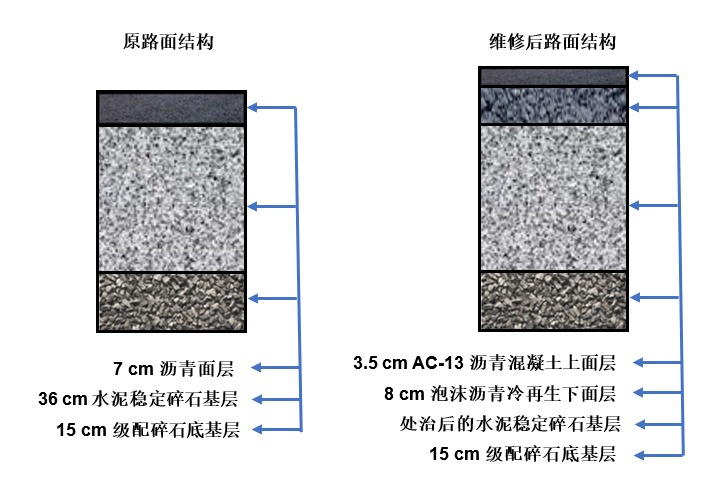

Firstly, local disease treatment is carried out on the original pavement base.,And then use W 380 CR On the original 7 cm On-site cold regeneration of foamed asphalt for asphalt pavement,Generate 8 cm Thick cold recycled layer of foamed asphalt is used as the lower surface layer,Finally, add 3 on top.5 cm Thick AC-13 Upper layer of asphalt concrete。

Construction process

W 380 CR The basic regeneration width of the cold regenerant was 3.8 m,One lane can be regenerated in situ at a times,This project has received the pre-milling cooperation of a Milling Machine,So that that reproduction width reach 4.5 m,Thereby reducingHere we goLongitudinal construction joints,Milling and mixing rotorYesUndercut modeAlsoOptimizeHere we goParticle shape of cutting material,ImprovementHere we goGradation of recycled mixture,And thenGuaranteeHere we goConstructionHigh quality。

W 380 CR The cold Recycling Machine cuts and crushes the old pavement material on the spot.,Add the foamed bitumen and water through a spray bar placed on the milling cover,And the cement pre-spread on the old road surface is stirred together,Because the milling and mixing rotor adopts a spiral structure,,The recycled material gathers towards the center。

The cold recycled material is then conveyed by a conveyor belt to the following Vogler Paver hopper,Paving by Paver,The foam asphalt cold recycling layer is rolled and formed by a Hummer Road Roller。The whole construction process adopts flow operation.,Only one lane is occupied,The opposite lane can be released normally.。

S205 medium repair works of pavement

Project overview

This project belongs to the project of improving the service capacity of Guangxi general national and provincial trunk highways in the new western land-sea corridor.,The project is 10 meters away from Beiliu City km,Distance to Yulin City: 108 km,Total length of the project route: 11.659 km。

In recent years, with the rapid development of regional economy,,Traffic volume and overweight Vehicles are increasing year by year.,As a result, pavement diseases continue to occur.,Road conditions are deteriorating.,There are mainly massive cracks on the original pavement.、Pavement diseases such as rutting and more longitudinal and transverse cracks,It seriously affects the safe operation and driving comfort of the highway.,As a result, the cost of highway maintenance and the cost of social Vehicle operation are increasing.。

The implementation of this project will improve the traffic capacity of the regional road network.,Improve the investment environment along the line,To provide a broader space for Yulin's investment environment.。

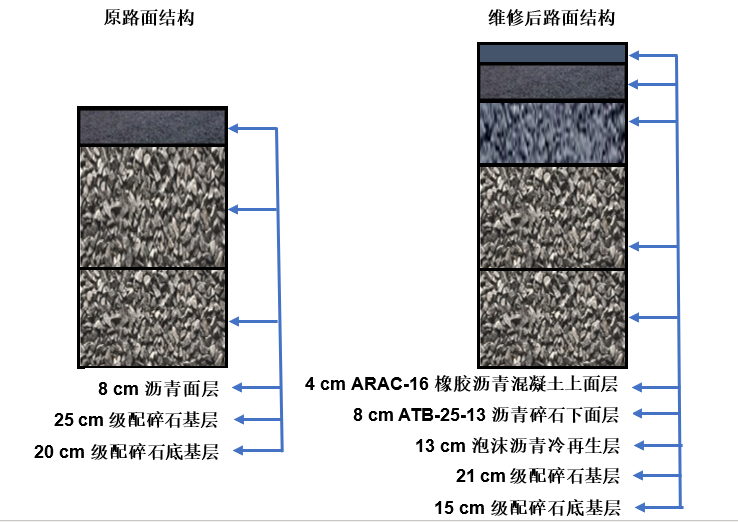

Application scheme

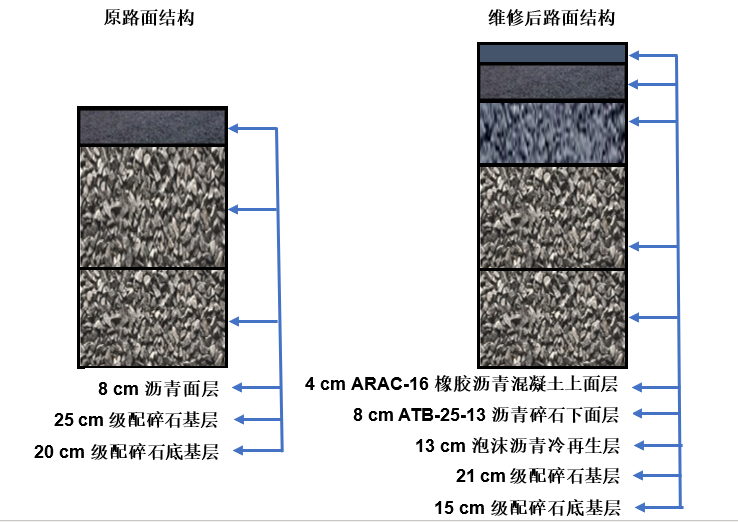

Direct use W 380 CR On the original 8 cm Bituminous surfacing and 4 cm Cold in-situ regeneration of graded crushed stone base with foamed asphalt,Generate 13 cm Thick foamed asphalt cold regeneration layer,Finally, add 8 on top. cm ATB-25 asphalt macadam underlayer and 4 cm ARAC-16 Upper layer of rubber asphalt concrete。

Construction process

The project adopts half-width construction.,Construction organization scheme for half-width passage,The half-width construction width is 4.5 m,Exceeded W 380 CR The width of the basic recycling operation,Therefore, it is necessary to adopt the side pre-milling and widening construction technology.。

A Wittgen medium Milling Machine was used in advance for the project. W 125 CF,Milling the ultra-wide old pavement material within the regeneration depth,Milling and planing materials are temporarily placed in W 380 CR In the working area of。W 380 CR The remaining width of the old pavement material is then milled and crushed,Meanwhile, the pre-milling materials are mixed together to form a uniform cold recycling mixture,Delivered to the rear Vogler Paver hopper。

The Vogler Paver mixes the evenly mixed cold recycled mixture to the full recycled width of 4.5 m Carry out paving,Finally, it is rolled and formed by a Hummer roller. cm Thick foamed asphalt cold regeneration layer。

After the emulsified asphalt tack coat is sprayed on the surface of the cold recycling layer and the emulsified asphalt is demulsified, the traffic is temporarily opened.,Minimize disruption to traffic。

Complete dense core sample taken out after construction

W 380 CR Advantages of cold in-place recycling construction technology

1

The cost is low:100%Recycling old pavement material,Reduce the use of new materials;Way of on-site regeneration,Reduce the cost of round-trip transportation of materials;And carry out at normal temperature.,Cost reduction in fuel consumption;

2

High efficiency:One lane can be regenerated at one times,And that mil is completed at the same time.、Broken、Addition of foamed bitumen and water、Mixing and other processes,And use a synchronized paving proces,Improve construction efficiency,The construction period can be shortened;

3

Good quality:The undercutting method is adopted,Ensure the gradation of recycled material,At the same time, due to the use of Pavers to pave recycled materials.,Flatness of cold regeneration layer、Thickness, cross slope and other indicators can be accurately controlled.;

4

Less pollution:Due to significant reduction in fuel consumption,Thereby greatly reducing carbon dioxide emissions.,There is data to show that,At least 80% less%Carbon emissions。

Wei has something to say

W 380 CR The construction efficiency of the cold Recycling Machine is about 8000~10000 m²/God,May be shortened by at least 1/3 Construction period;At the same time, it only needs to close half of the width for construction.,Traffic can be temporarily opened after the cold recycling layer is compacted and the emulsified asphalt tack coat is spread.,Reduce interference to surrounding traffic;And the quality of the cold regeneration section temporarily opened to traffic is stable.,Therefore, it has won the praise of owners and construction units.。

The successful application in Guangxi Province Road Maintenance Project,It's a good start.,This low carbon、Environmental protection、The efficient maintenance method of asphalt pavement will have a broader application prospect in Guangxi。