As the advantages of AeriaL Work Platforms are widely recognized,

There are more and more application scenarios.

How to keep the Vehicle“Fighting capacity”

Safer、More reliable、More durable?

Xiaobian specially brought one.

Specifications for Use of Aerial Work Platform

Please read carefully,Check it carefully!

One、Precautions for Vehicle use in winter

1

Complete Vehicle inspection

Before use,Inspect the Vehicle for missing or damaged part。After the Vehicle is powered on,No alarm in electrical system。

2

Check the hydraulic system

Check whether the hydraulic oil type can meet the ambient temperature;Check whether the hydraulic oil is sufficient;Check whether the hydraulic oil is emulsified、Metamorphism。

3

Engine system check

Before use,Preheat the engine and confirm that the preheating system is normal.,The temperature is-10℃And below,Multiple interval preheats are required。Check the following before use:

1. Check whether the antifreeze type of the engine cooling water tank meets the environmental requirements.,Otherwise, replace it;Check whether the antifreeze fluid is sufficient,No leakage。

2. Check whether the engine oil type meets the requirements of ambient temperature.,Otherwise, replace it;Check whether the oil level is normal,No deterioration、No leakage。

3. Check whether the diesel model meets the requirements of ambient temperature.,

Otherwise, replace it;Check whether the diesel oil level is sufficient,The oil is free from deterioration、No leakage;Timely drainage of oil-water separator,Each filter is smooth、No clogging。

4. The air intake system is smooth、No clogging。

5. Check the battery power,Make sure the battery power is sufficient,Static voltage 12.3VAbove;And ensure that the Generator can charge the battery normally after the engine is started.。

4

Precautions for Vehicle startup at low temperatures

1. According to the cold weather.,Warm up the engine before starting。

2. Run the engine for 5 minutes after first starting the Vehicle,Do not operate the Vehicle until the engine is warmed up。

3.It is recommended not to start the Vehicle frequently。If the Vehicle is used for a short time after starting,,Start continuously after flameout,In this way, the battery is easily pulled down.,Not good for starting。For a relatively short job,Like painting the walls,It is recommended to work at idle speed,Keep the engine running。

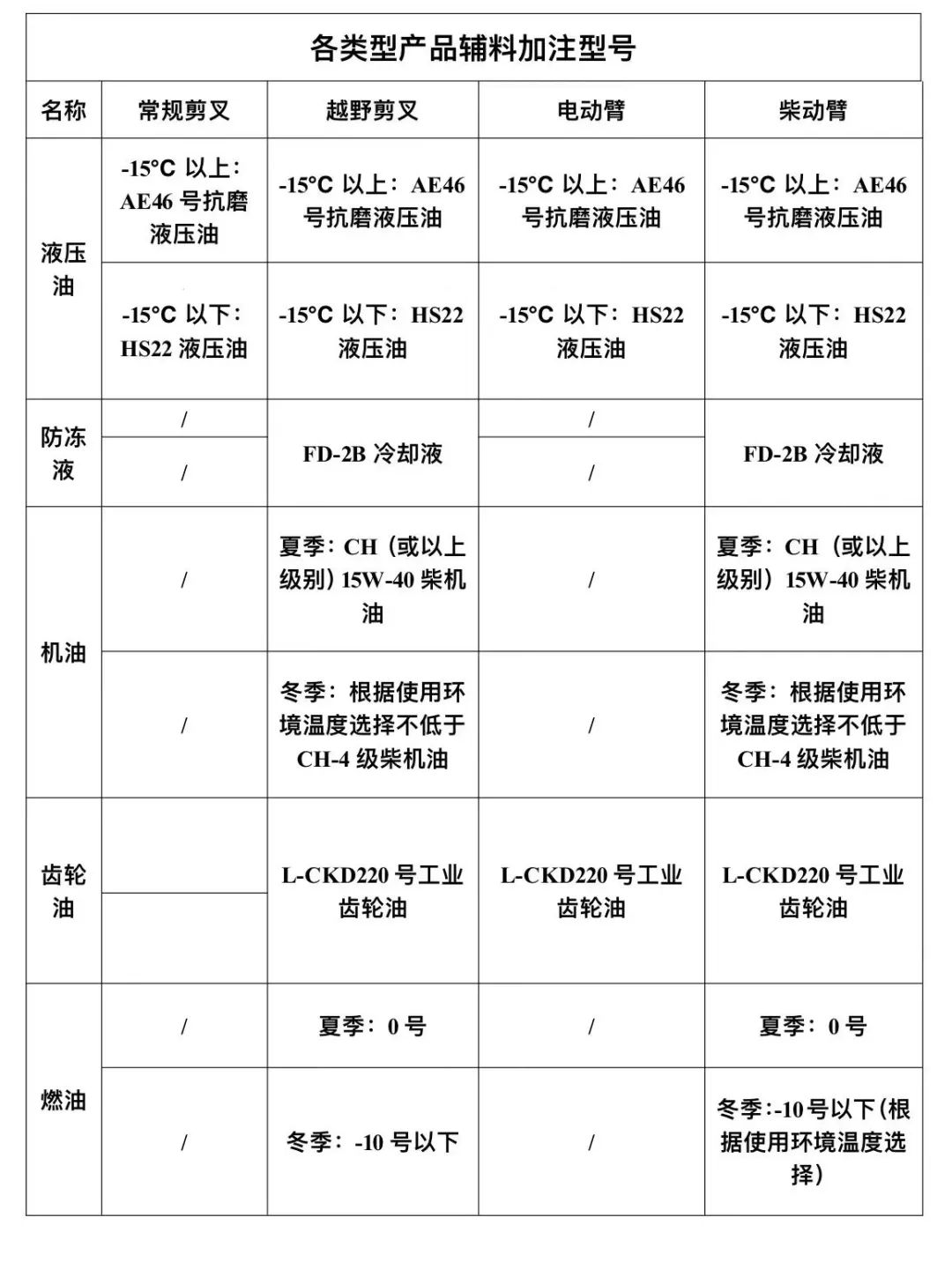

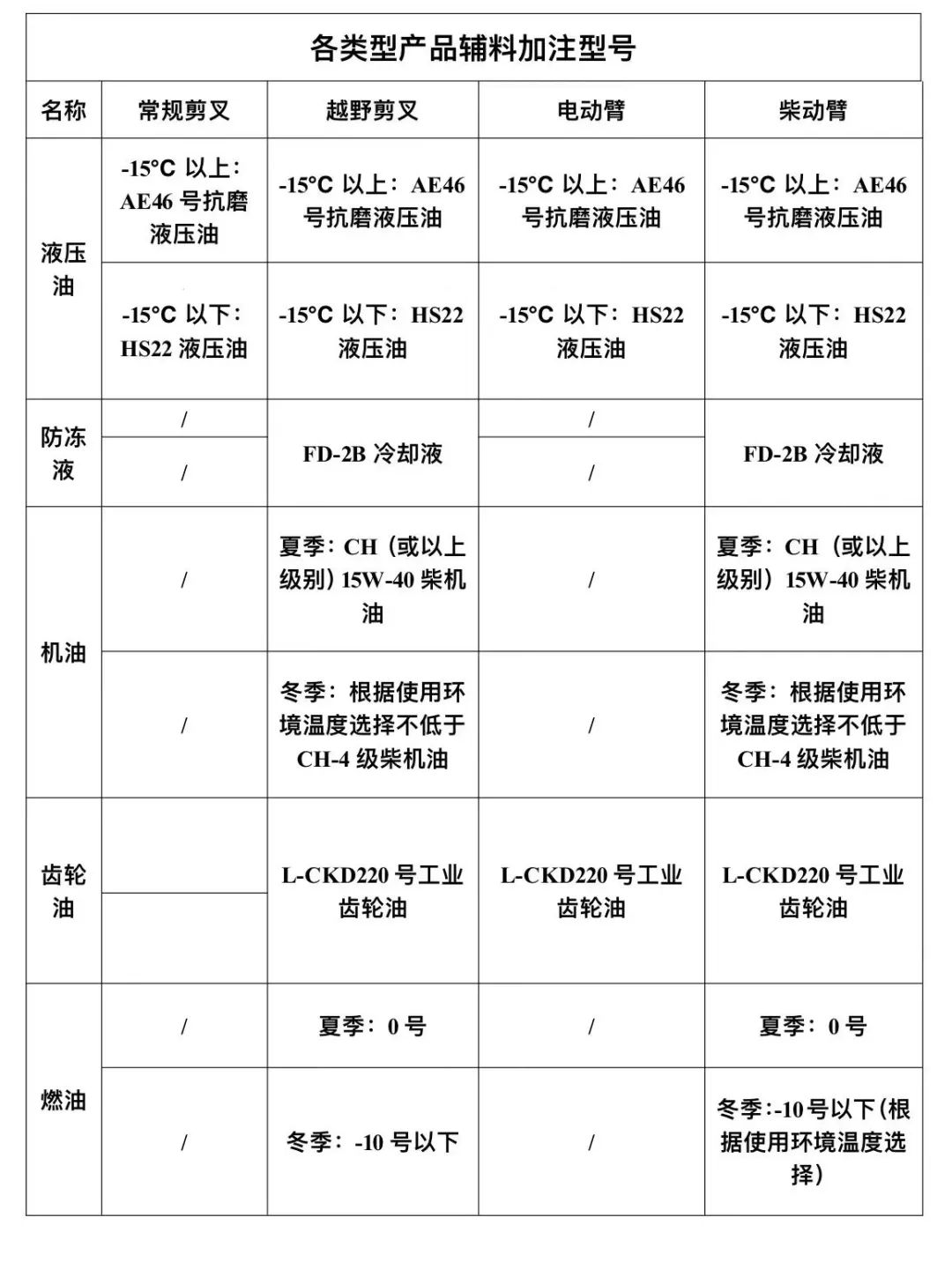

Two、Vehicle Oil Model Comparison Table

Three、Precautions for storage and parking of aerial work platform

1

Lectric aerial work platform

1. After the Vehicle is used up,Please clean the Vehicle and ensure that the Vehicle parts and performance are in good condition.。

2. Check the battery pile head and connecting line;If the battery can be maintained, the water level of the battery should be strictly checked and replenished.。

3. Fully charge the Vehicle,Close the battery and electrical door and park in a place that is not easily covered by snow or rain.;All vehicles should be parked as far as possible to avoid strong wind.。

4. For the scissor vehicle, please unplug the platform control handle and store it.,Turn off the main switch of battery。

5. To keep the battery active,Extend battery life,If stored in excess of15 days,Please supplement electricity to the vehicle in time.。

2

Diesel-driven aerial work platform

1. After the vehicle is used up,Please clean the vehicle and ensure that the vehicle parts and performance are in good condition.。

2. Check the engine oil and check the battery power and Generator function to ensure normal engine performance.,Start the vehicle to ensure that the battery is fully charged。

3. Close the hood and the platform electrical cover, and park the vehicle on a safe and reliable ground.;All vehicles should be parked as far as possible to avoid strong wind.。

4. If the vehicle is parked for a long time, cut off the main power supply of the vehicle.,To avoid slow discharge of the battery。

5. If the vehicle is parked over15 days,Please start the engine in time to charge the battery.,In order to avoid battery feed caused by long-term parking。

Four、Precautions for vehicle maintenance and repair of key components

Please follow our product maintenance manual to maintain the vehicle regularly and keep the maintenance record.。The main maintenance contents of the vehicle are as follows::

1. Complete vehicle inspection,Contain:No parts are damaged or missing。

2. Inspection of wire rope,Contain:Stretch the wire rope、Recover the wire rope。

3. Solid lubricant maintenance,Contain:Bearing、Swing gear、Boom slide。

4. Maintenance of liquid lubricating parts,Contain:Reducer、Brake、Engine、Hydraulic system。

5. Safety performance inspection,Contain:Action test、Emergency function test、Vehicle sensor calibration、Engine performance check、Battery performance check。

Five、Precautions for maintenance of vehicle safety performance

1

Action test

Test whether all actions of the vehicle are normal,The movement speed is steady、Start and stop smoothly。

2

Emergency function test

Test whether the upper and lower control emergency pump of the arm Truck can operate normally.;Check whether the emergency falling function of the shearing forklift is normal。

3

Vehicle sensor calibration

Vehicle sensors act as the eyes and ears of the vehicle control system,Provide basic judgment information for vehicle safety performance,Reliable performance of solid vehicle sensors is particularly important。Check the accuracy of the sensor value displayed on the display and the actual value of the vehicle in three different States.(Error Range≤10%),If any deviation is found, please contact our regional service personnel.,Conduct calibration under professional guidance。

1. Chassis tilt sensor inspection method

Drive the vehicle on 3 different surfaces,Measuring chassis inclination sensor mounting plateXShaft andYThe actual angle of the axis direction is compared with the display angle of the display.,Check for errors。

2. Inspection method of boom angle sensor

Luffing the vehicle jib to the lowest angle、0 degrees、Maximum angle,Measure the angle of the lower part of the boom respectively.,Comparing the measured angle value with the display angle of the display,Check for errors。

3. Inspection method of boom length sensor

Lift the vehicle crank arm and telescopic arm to 0 degree,Extend the arm to full retraction.、Half stretch、Limiting full extension,Measure the vertical distance from the most front extension of the platform bar to the center of the center rotator.,Compare the measured length to the display amplitude,Check for errors。

4. Inspection method for platform weighing system

Place 0 in the vehicle platform railkg、200kg、Maximum load,Compare the actual weight with the display weight,Check for errors。

5. Inspection method of platform angle sensor

Actual levelling of the vehicle platform bar to 0°、﹢5°、﹣5°Compare actual and display platform angle,Check for errors。

Please follow our product maintenance manual to maintain the vehicle regularly and keep the maintenance record.。

Your affirmation,It is the driving force for us to move forward.!