With the continuous implementation of the dual-carbon policy,,All walks of life have been released one after another“Decarburization”Road map,Green low-carbon transformation continues to accelerate。November twenty fifth,At the opening site of the new base of Cummins East Asia R & D Center,Cummins showed the company.“Zero carbon target”Under the latest multi-power solutions,Help Chinese customers achieve full life cycle carbon reduction。

Vice President of Cummins,Sai Junfeng, Chief Technology Officer of China(Stephen Saxby)Express:“As a provider of diversified power,The application market we are facing is very complex.,Large-span application scenarios bring greater technical challenges.。But Cummins has always been committed to zero carbon.,We understand the needs of our customers,At‘Zero carbon target’Under the guidance of strategy,Apply existing and new technologies to products,Meet different application requirements,Helping the industry's energy transformation,Promote the carbon to reach the peak、Carbon neutral target achieved。”

Aim for Zero Carbon,For multi-scenario applications,Cummins is low-carbon at the event site.、Zero-carbon power solutions are all unveiled。

New high efficiency diesel engine

After more than 100 years of continuous iteration and upgrading,,Cummins diesel power classic products emerge in an endless stream,For different markets around the world,Customized development of power solutions for different application models and work scenarios。In China,Cummins has been deeply engaged in the market for nearly 50 years,Product coverage is light、Medium、Heavy duty engine platform。

Especially in the last 10 years.,Constantly bring forth new ideas according to different application market demands in China,Apply the most advanced technology of Cummins,Ensure that the engine meets the emission regulations.,Continuously improve engine efficiency。The first 15 in China last yearLNew diesel engine,Once again defines the heavy-duty engine standard,It has a maximum of 680 horsepower,Mass production 48%Thermal efficiency leads the industry。

In addition,Cummins plans to launch a new generation in 2023 to meet the four-stage fuel consumption,New Products of China VI Emission Regulation,And will launch the next generation of more competitive heavy-duty platform upgrades.,Including diesel、Development of natural gas and hydrogen internal combustion engines。

Activity site,Cummins' New Generation of Non-road National IV Power Unveiled。Cummins Guosi Power optimizes product characteristics in an all-round way,Through the deep linkage with the main engine factory,In automation、Intelligence and digitalization.,Achieve a higher level of cost reduction and income increase。Optimized by intake and exhaust system、Combustion system optimization,Integration and optimization of hydraulic systems with different equipment,The operation efficiency is significantly improved under different working conditions and application scenarios.。

National VI Natural Gas Clean Power

As a clean energy source.,Natural gas is“Carbon emission reduction”An important starting point。For the Chinese market,Cummins has tailored the new national six natural gas engine products.,Includes 15N、12N、6.7N。Among,6.7NThe natural gas engine is making its debut.。This product is smaller in size.,Lighter weight,However, the performance of power and torque is almost comparable to that of diesel engines with the same displacement.,190-280 horsepower,Maximum torque 1100 Nm。

New 6.7NNatural gas engines will be mainly used in China.、Cards in India and Europe、Passenger car and special Vehicle field。In addition to lightweight design,More than 100 natural gas turbine components and key system innovations,Greatly improve the reliability of natural gas engine under extreme conditions;High-precision gas injection system ensures precise control of air-fuel ratio,Improve engine economy and emission performance。

Multi-fuel engine platform

At the same time,Focus on future ultra-low emission standards。Cummins also pioneered a multi-fuel engine platform this year,In the case of common parts and components,Biodiesel can be used、Hydrogenated vegetable oil(HVO)、Renewable natural gas and hydrogen and other low-carbon、Zero carbon fuel,Provide users with a lower cost decarbonization technology path。The thermal efficiency of the platform diesel engine can reach 48-50%,The thermal efficiency of the gas engine can also reach 43-45%。

15HHydrogen internal combustion engine

As an important product of Cummins multi-fuel engine platform,Hydrogen internal combustion engine can use green hydrogen zero-carbon fuel,Develop new technical approaches for energy conservation and emission reduction。Activity site,Cummins 15LHydrogen internal combustion engine also made a brilliant appearance.。

Hydrogen has unique physical and chemical properties.,For example:Wide flammability limit,Short ignition delay time。How to maximize thermal efficiency and power,It has always been the focus of research and development of hydrogen internal combustion engines.。Cummins 15HHydrogen internal combustion engine uses direct injection、Lean combustion,The base machine has up to 250barDetonation pressure capability,Achieve maximumBMEP 24bar,Maximum output power of 550 horsepower,Maximum torque 2600 Nm,Design thermal efficiencyBTEUp to 44%,Significant improvement in thermal efficiency and power performance。

15HHydrogen engine through a flexible overhead cam system,Improve the cooling system,Reduce frictional resistance,Ffectively avoiding the process of converting the fuel of a diesel or natural gas engine into hydrogen fuel,Performance limitations and efficiency losses occur;At the same time,The engine features an industry-leading combustion chamber design,And based onpent roofTumble combustion system,Better fuel mixing、Gas flow and turbulence generation,Boosting fast combustion of hydrogen。Relying on advanced in-cylinder direct injection technology,40barInjection pressure,Perfect balance between hydrogen supply efficiency and in-cylinder mixing optimization,Maximize efficiency。

With 15HAt the same time, a hydrogen internal combustion engine was unveiled for the Chinese market.,Customized zero-carbon heavy-duty concept Truck with hydrogen internal combustion engine。The Vehicle is equipped with Cummins 15LHydrogen internal combustion engine,10 70 are integrated in the Vehicle chassisMpaA hydrogen storage tank,It can store about 53 kilograms of hydrogen.,Auxiliary hydrogen storage tanks can also be installed as required.,Potential range of 800 km(Calculated by hydrogen storage capacity of 80 kg),Meet the requirements of heavy-load, long-distance and high-speed logistics,Heavy haul intercity logistics and other needs。

Hydrogen energy industry chain“Preparation, storage and application”

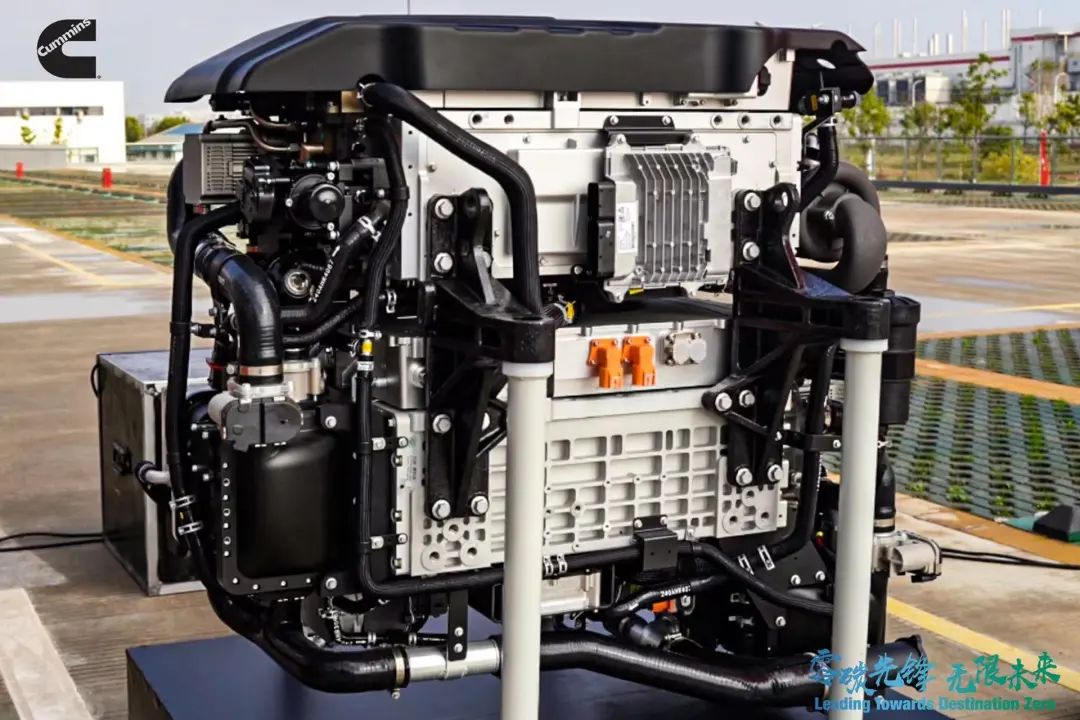

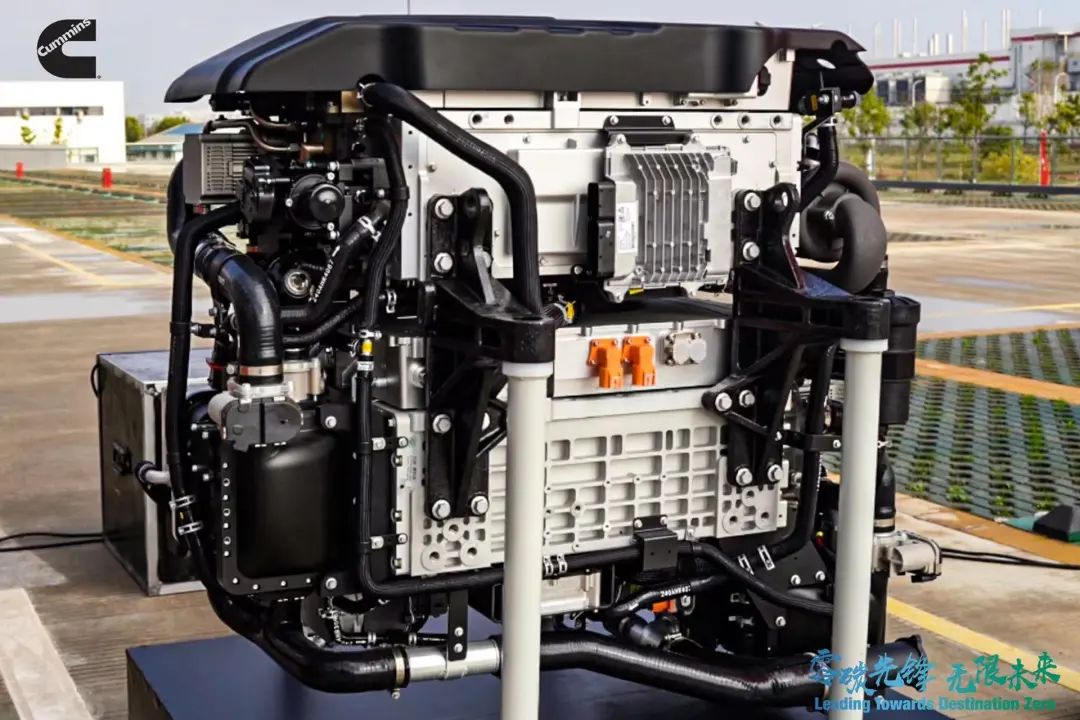

As one of the most promising clean energy sources,,Hydrogen energy provides new opportunities for the sustainable development of various industries。In the field of hydrogen energy application,Cummins fuel cell technology can power multiple application scenarios,Including the bus、Truck、Rail Transit、Ships and power generation。The forward-looking high-power fuel cell unveiled this timeHD240 Rated power over 200kW,Inheriting high stability of Cummins products、On the basis of reliability,Further optimize the product structure and control,High power density,Excellent cold start performance,It is trunk logistics、Provides an ideal zero-carbon clean power solution for long-haul heavy duty applications。

At the same time,Cummins Continues to Explore Low Carbon Energy,Its proton exchange membrane water electrolysis technology can be applied to industrial manufacturing.、Chemical smelting、Integrated renewable energy solutions and other scenarios,Help the industry achieve the long-term goal of green decarbonization。End of 2021,Cummins and Sinopec Capital Enze Fund at 50:Jointly invest and set up a joint venture company in Foshan,Will be the leading proton exchange membrane(PEM)Localized research and development of hydrogen production technology by water electrolysis in China、Production and sales,Hydrogen production technology based on water electrolysis technology and renewable energy,Promoting the Development of Green Hydrogen Production Scheme。

New Energy Power China Headquarters and New Energy R & D Center in Shanghai cover the stack of hydrogen production equipment by electrolysis of water.、Fuel cell engine and its core components、High-pressure hydrogen storage cylinder system and other businesses;The second phase of Cummins East Asia R & D Center in Wuhan is also equipped with a hydrogen power building.,It will be put into use soon。Learn from the localization experience of Cummins traditional business in China for more than 40 years,Cummins New Energy will join hands with upstream and downstream industries,Jointly drive the prosperity and development of China's hydrogen energy and fuel cell industries。

Diversified powertrain solutions

Deeply integrated value partner

Strong power performance、Low-carbon environmental protection performance,It is inseparable from the deep integration and system operation of each module of the power system.。Cummins' Product Design Through Integrated Power Chain、R & D and manufacturing,Help customers achieve energy saving and carbon reduction while operating efficiently。

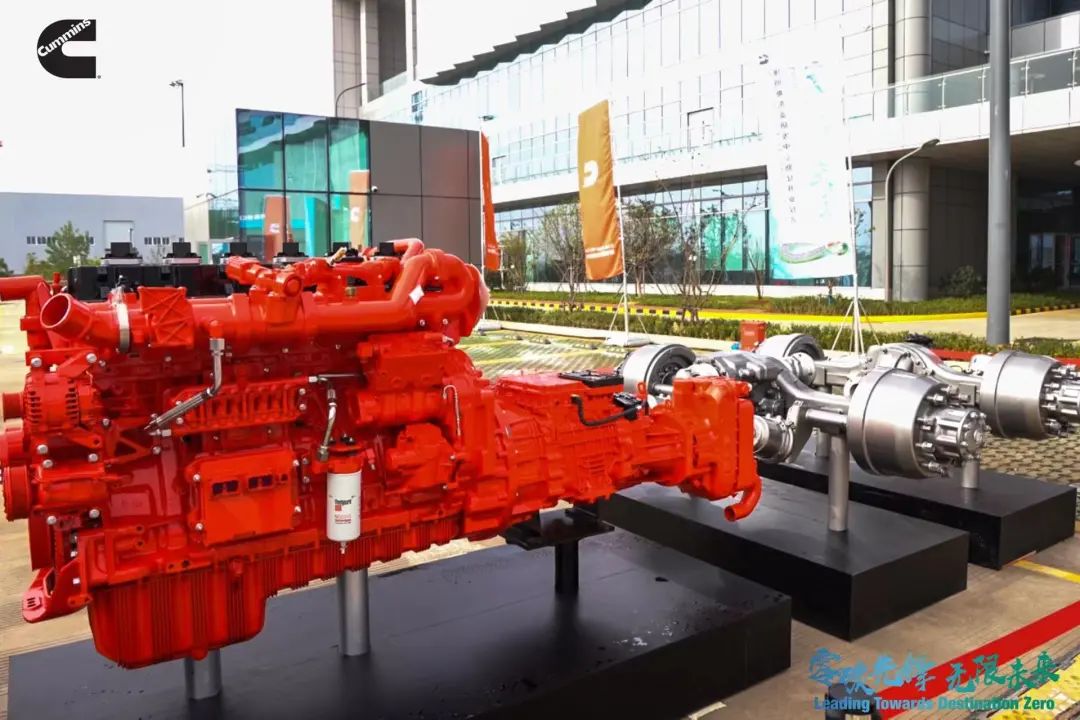

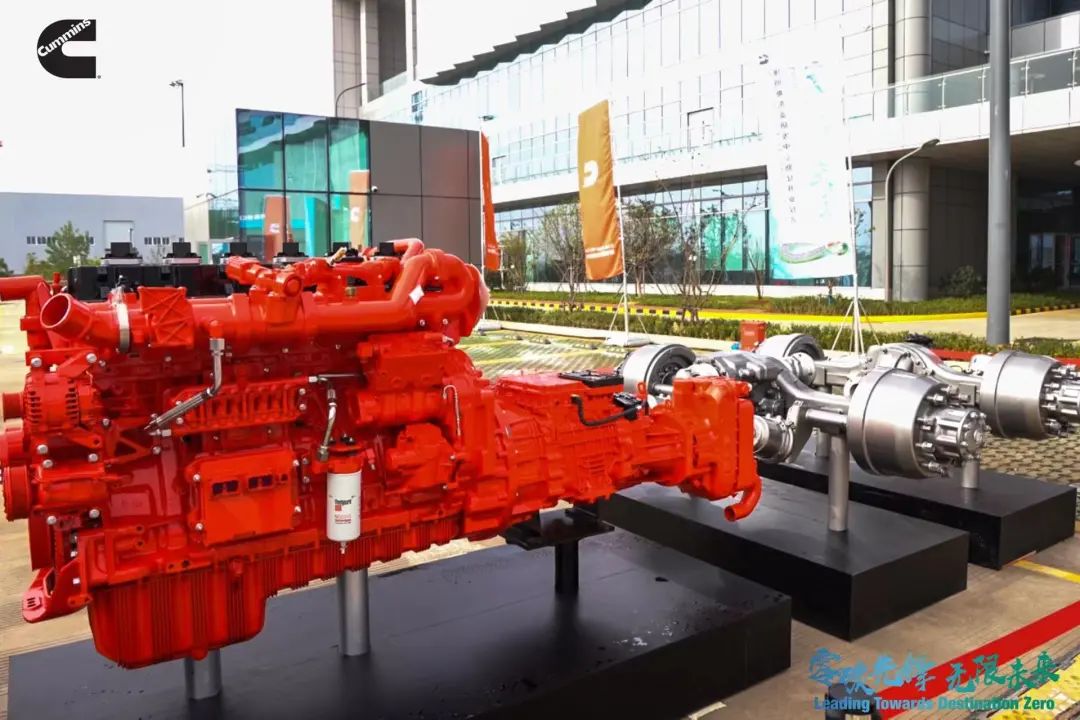

Appeared at the eventCummins Integrated Power Chain Products(15NNatural gas engine+WinAMT+Meritor axle),It gives full play to the advantages of deep integration of each module.:For local working conditions and market demand,New optimization of the engine combustion control system,Improve combustion efficiency;Optimize the winningAMTTransmission control software,And select the best rear axle speed ratio,Lower fuel consumption、Higher efficiency、More low-carbon and other advantages,Become a value partner for efficient transportation。

At“Zero carbon”On the way,Cummins will continue to develop integrated power chain technology,Upgrade intelligent brain control technology,Realize deep integrated control of power chain,Improve cycle efficiency in Vehicle operation;At the same time,Continuous development of power chain brake system,Brake the engine、Hydraulic retarder、Brake combinationAMTShifting for integrated control,To provide customers with a more optimized power chain braking system。In addition,The company will continue to strengthen industry cooperation.、Collaborative innovation,For all kinds of power、Appropriate power chain solutions for different working conditions,Help achieve zero carbon goal。