The first plane to land at the new yogyakarta international airport (YIA) on the Indonesian island of Java was an A320 from Jakarta. Eleven vltgen cement Pavers played a vital role in the construction of the airport. As many as 20 million passengers a year will fly through the airport once it is completed. Yogyakarta international airport has a terminal area of 130,000 m2. , the new airport will replace the limited Adisutjipto airport.

no fear of challenges, wittgen group to provide customers with quality construction solutions

One of the biggest challenges of yogyakarta airport is the short construction period of the road surface. To complete the project on time, a safe and reliable construction plan is needed. This is what wittgen group sales and services Singapore is doing with Indonesian distributor PT Gaya Makmur Tractors to quickly and accurately deliver to clients. The pavement construction scheme is not only equipped with reasonable paving scheme and slip-form paving unit, but also provides perfect technical support and on-site application consulting service.

outstanding quality makes the concrete pavement surface particularly eye-catching

During the construction of yogyakarta international airport, a construction fleet consisting of 4 SP 64, 6 SP 500 and 1 SP 84 I slip-form Paver accurately and efficiently paved the runway, taxiway and apron of 3,250m long and 45m wide.

Vitergen's four slide-form Pavers are used for economical and high-precision paving of concrete pavement in YIA

Depending on the area, the paving width of cement concrete slabs is 2 m, 5 m or 6 m, and the paving thickness is 50 cm. During the construction process, the transmission rods are placed on the steel cage at a horizontal distance of 30 cm. In addition, steel mesh is preset in the concrete pavement to improve the strength of the concrete pavement.

& other; The quality of concrete pavement is excellent. Throughout the &; Andek Prabowo, President of PT PP Presisi Tbk, PT PP (Persero) Tbk group Moreover, the construction efficiency is also very high. Throughout the &; It is understood that the second phase of the airport project will complete another 65,000. The runway will also be lengthened by 350 m. By then, the vetgan slideform Paver fleet will be ready and ready.

Wittgen's high-precision slide-form Paver can be paved 90 ° Concrete corner

wittgen — Airport construction expert

Wittgen is an ideal technical and quality partner for airport construction, regardless of technical requirements and location. This is mainly due to its wide product range, rich expertise of application experts and reliable services in the world. The wide range of use, so that wittgen sliding form Paver can meet the construction site of various requirements — No matter where you are in the world. For example, they can be easily and accurately paved with slide-form concrete pavement, without the need for paving in the construction mode of vertical steel mould and slide-form Paver commonly used in other airports.

Vitgen sliding form Paver can ideally meet a variety of application needs, and can pave the concrete pavement with high precision, instead of using the construction method of vertical steel mould and sliding form Paver commonly used in other airports

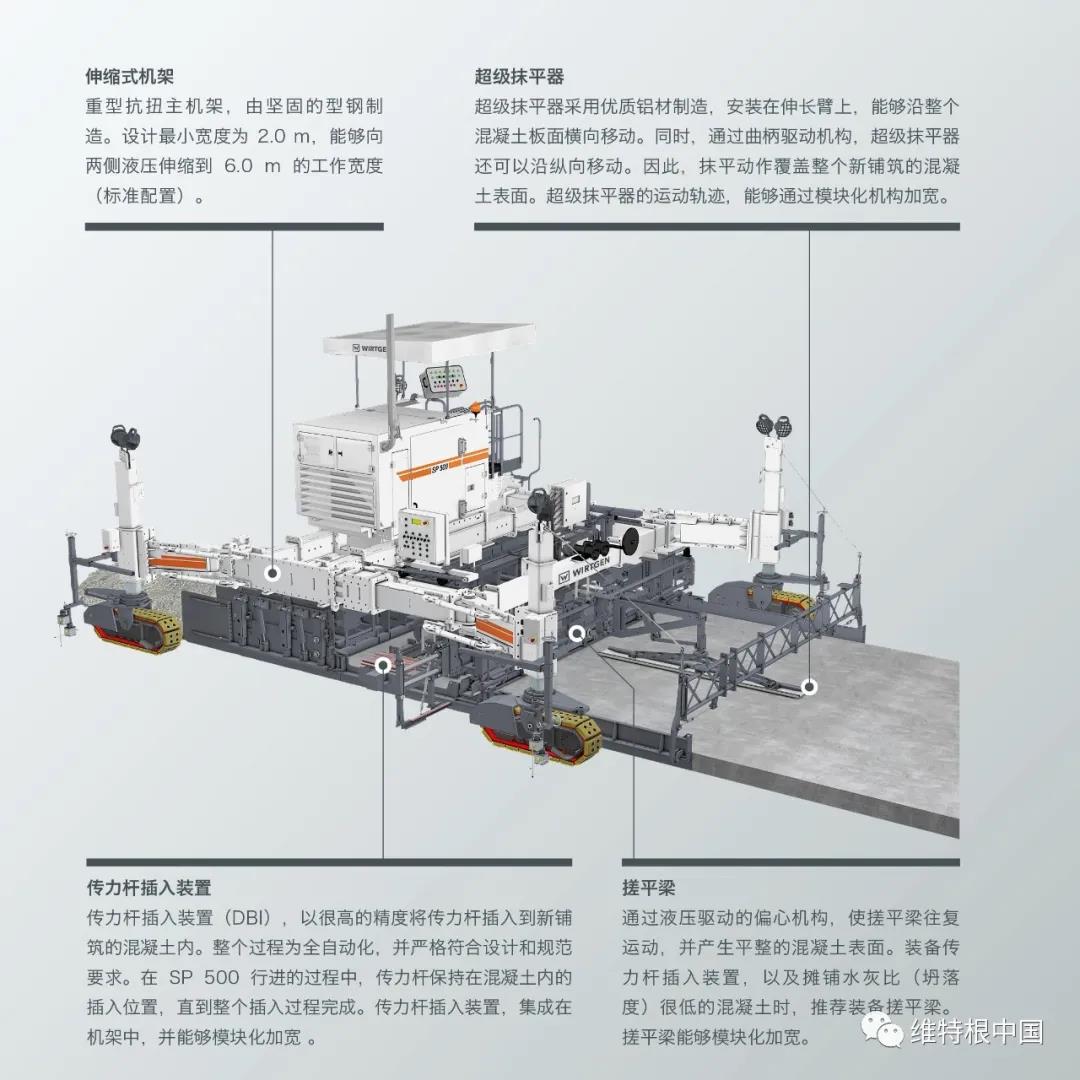

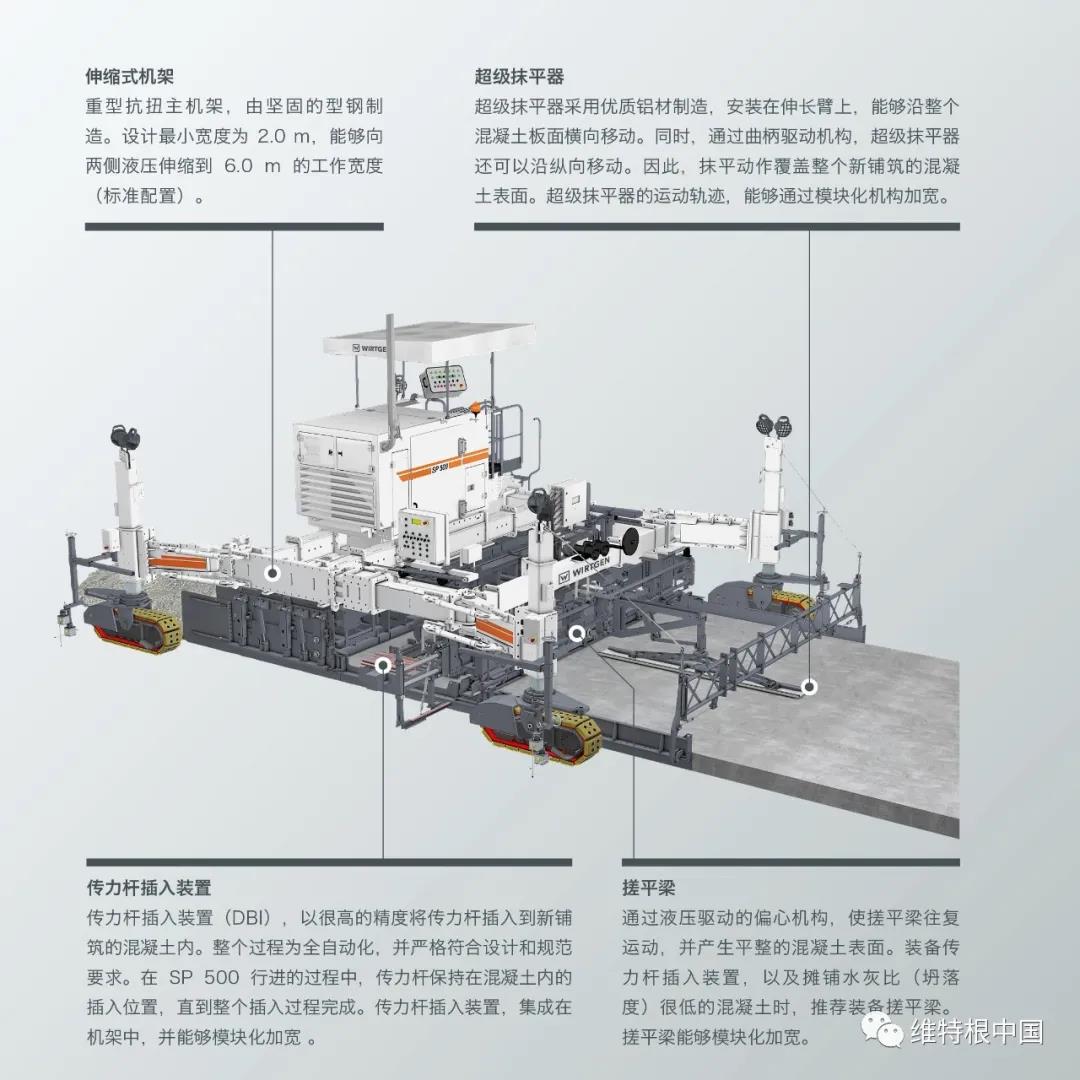

vitgen SP 500 device highlights:

Modular design ensures that the machine has a standard spread width of 2 m to 6 m and a spread thickness of up to 40 cm

Cloth plough or cloth auger can evenly distribute concrete

Advanced leveling and steering control system ensures accurate paving effect

Force transfer rod or pull rod can be inserted automatically, which will not interfere with pavement construction

Wittgen SP 500 slip-form Paver is the representative of high quality and high efficiency of automatic Paver construction, and it is also an indispensable and important equipment for concrete Paver construction of airport runway. With many advantages, victor root SP 500 slip-form Paver can bring higher economic benefit for clients, this effect has been include the Hong Kong international airport, Beijing daxing new international airport, chongqing international airport, chengdu shuangliu airport, Shanghai pudong international airport, Qingdao jiaodong international airport, guangxi yulin f continous airport and so on a series of China's domestic airport construction projects has been fully verified.

& have spent