Xiao wei has said: compared with the north of China, the temperature changes in the four seasons are relatively insignificant. There is no winter rest period caused by low temperature in the construction. The equipment can be operated all year round. Therefore, customers often want to repair and maintain equipment as soon as possible to minimize downtime. In fact, the construction time of equipment is not the direct factor that determines the construction efficiency, but the effective working time when the equipment is in good working condition is really important.

Therefore, many experienced equipment users in the construction field, when choosing to carry out special equipment or workshop overhaul, not only look at the maintenance agencies “ Commitment throughout the &; During the repair period, more attention is paid to the performance of the equipment and the repair rate of the equipment. The service of five star repair workshop in foshan, China solves these problems well.

Today, wei will take you to the five-star maintenance workshop of witgen south China in foshan, guangdong province, to know what is the ideal workshop maintenance.

With the establishment of a world-class production plant in langfang, hebei province, and the establishment of a regional headquarters in east China in taicang, jiangsu province, wittgen group's strategic layout in the Chinese market is progressing steadily from north to south. Foshan, located in the hinterland of the pearl river delta, is an important node city in the guangdong-hong kong-macao greater bay area and an important manufacturing base in China. In March 2019, wittgen China's third five-star repair workshop was officially opened with the opening of the south China regional sales and service center located in foshan, guangdong province.

win at the starting line

Foshan repair workshop from the start of the establishment set a high starting point, because there are langfang, taicang repair workshop experience can be used for reference, so as to eliminate the process of exploration. Foshan maintenance workshop is an important part of the rebuilt witgen south China regional sales and service center, so it is equipped with new maintenance facilities and tools in strict accordance with the standard planning of the group headquarters from design to construction. At present, foshan maintenance workshop has 8 multiplexed maintenance stations, which can meet the needs of all types of maintenance.

Professional maintenance equipment is important, excellent service personnel is fundamental. With the establishment of foshan maintenance workshop, foshan training center was also completed. The training center close at hand enables the maintenance personnel in foshan repair workshop to receive skill training frequently, relying on the systematic training system formed by wittgen group over the years.

& have spent  & have spent

& have spent

Standing on the shoulders of giants, so that foshan repair shop growth faster. Foshan workshop maintenance team of one of the major, in the construction machinery industry has had 20 years of experience lu yongqiang engineer said, foshan maintenance workshop since the establishment of langfang, taicang two maintenance workshop team has maintained close contact, langfang headquarters often send senior engineers to foshan for face-to-face guidance.

Foshan maintenance workshop a total of 9 engineers, not only have more than 10 years of maintenance experience of senior technicians, and every service engineer in the team are skilled in business. All-rounder ” . In addition to the biweekly systematic training provided by the company, the workshop service team will also summarize the specific problems in the maintenance and apply for additional training to ensure that every member can constantly update the maintenance knowledge and improve the technical level.

strictly control standard quality assurance

Since its birth, foshan maintenance workshop has been adhering to the rigorous and serious tradition and unified strict standards of witgen group. For example, the parts used in maintenance are the original parts of the factory. In the eyes of service engineers, this is also an important measure to guarantee the quality of equipment maintenance, extend the life of equipment and protect the interests of customers.

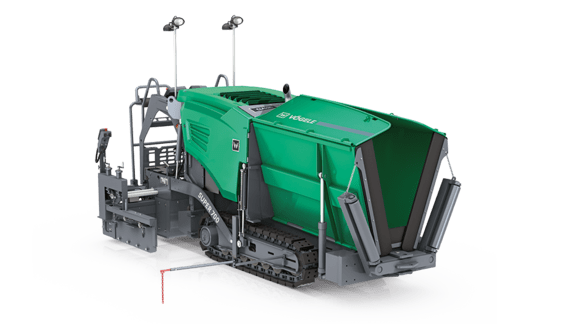

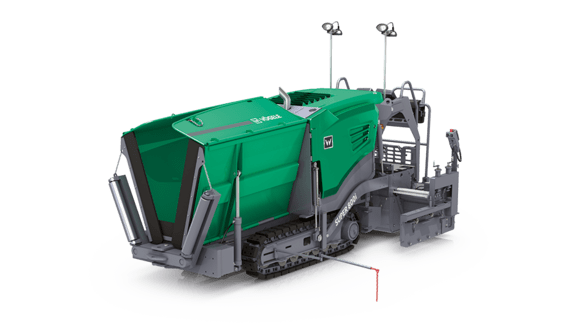

The equipment of all brands of wittgen group has excellent quality and is known for its excellent performance, and the components of the equipment are one of the important factors to ensure the excellent performance of the equipment. Therefore, the use of auxiliary parts and inferior parts will not only cause impairment to the performance of the equipment, but also may cause serious damage to the equipment. It is difficult to guarantee the quality of spare parts when repairing equipment in an outside repair shop.

Lu yongqiang introduced, because the use of non-original parts caused by machine damage is very common. In equipment maintenance piece in common use, such as hydraulic oil filter, oil-water separator filter as an example, the deputy factory is cheap, it looks as if saved cost, but in reality to the equipment damage is very large, filter was not up to standard, particle pollution into the system, like blood was polluted, will affect the service life of equipment, in the long run.

Foshan maintenance workshop environment, equipment and maintenance operations are strictly in accordance with the German company standards, the grasp of details do not relax. & other; The hydraulic part is just like the blood vessel of engineering machinery. Once the particle pollutant enters, it will cause great harm to the hydraulic system. Our equipment configuration and anti-pollution control measures are strictly in accordance with the requirements of the group. It is possible to avoid contaminate the equipment during maintenance, but it is difficult to guarantee this from the outside repair shop. Throughout the &; Lu yongqiang gushed about the details. Non-standard operation will bring secondary damage to the equipment. As the maintenance workshop of the manufacturer, we have a deeper and more comprehensive understanding of the equipment. Through standardized operation, the equipment we have maintained is closer to the level of the new machine. Throughout the &;

After the maintenance of the equipment before the factory will also be in accordance with the performance parameters of the new machine assembly to carry out quantitative testing, so for the maintenance of the quality of the factory equipment can be evaluated. And outside the repair shop, the lack of professional maintenance tools, some even torque wrench are not, all artificial feeling, nature is far from standard. It is difficult to maintain the quality of the equipment, repair is good luck.

win customers with high efficiency and high quality

Foshan and surrounding areas like spring all year round, without the situation of winter shutdown, the equipment can work all year round, so the customer maintenance equipment more attention to service efficiency. In the process of maintenance, the lack of spare parts is one of the reasons for the expected maintenance lag. Thanks to the strong strength of wittgen China, foshan spare parts warehouse has sufficient spare parts types and inventory, and supports each other with taicang and langfang spare parts center. In terms of spare parts satisfaction rate, customers need not worry. Spare parts supply has the confidence, the service engineer technology is excellent, the commitment time limit can and the actual maintenance time limit plan on. The equal sign & throughout; .

What's more, efficiency is not simply the quick repair out of the factory, but to ensure the quality and quantity, lower repair rate is the fundamental to protect the interests of customers. Trustworthy and risk-free.

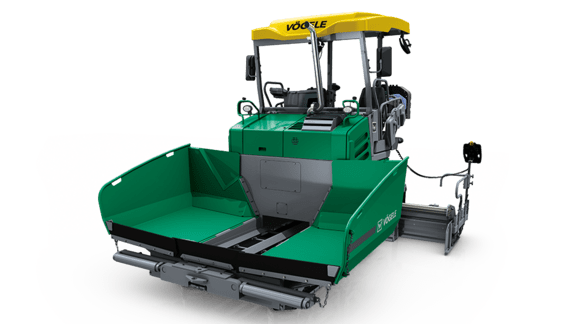

The quality service of wittgen China repair workshop has not only won them the recognition of customers in this province, but also made them famous. Not long after foshan maintenance workshop was established, some yunnan customers heard about their “ A good name is & throughout; Came all the way to investigate. & other; The customer spoke highly of us and immediately decided to ship the equipment to us for repair. Throughout the &; The Milling Machine W 2000 of the customer in yunnan has been working for more than 8000 hours, but it is unable to work. Considering the cost of repair, the customer proposed to replace the broken oil pipe at the beginning. Wittgen foshan service team, considering the interests of the customer, made a comprehensive test for the equipment, suggested to the customer according to the condition of the equipment, and replaced the whole Vehicle oil pipe. Finally, the equipment was tested after repair, and the dynamic performance and other indicators returned to the normal working state, which greatly exceeded the customer's expectation. After the repair of the equipment, from the factory to now has been working normally, the customer is very satisfied.

special winter workshop service

Distant customers often fret about high transport costs. In order to better serve customers, wittgen group has launched a winter maintenance special:

During the period of 31 March 2020, the pavement equipment can enjoy the following discount when it is repaired in the maintenance workshop of vitgen China langfang, taicang and foshan three major factories:

1. The total amount of a single maintenance is 300,000 yuan. Wittgen China is responsible for the single transportation of equipment within 1,000 kilometers from the maintenance factory;

2. The total amount of a single maintenance is 500,000 yuan, and wittgen China is responsible for the round-trip transportation of equipment within 1,000 kilometers from the maintenance factory;

Wittgen China foshan five-star repair workshop and its professional service team dedicated to professional, dedicated to work, ready to provide customers with quality services. If your construction machinery equipment happens to have the need to repair, please immediately contact wittgen local agent in China. Wittgen China foshan 5-star maintenance shop on call at all times. D & throughout; Your service!

& have spent