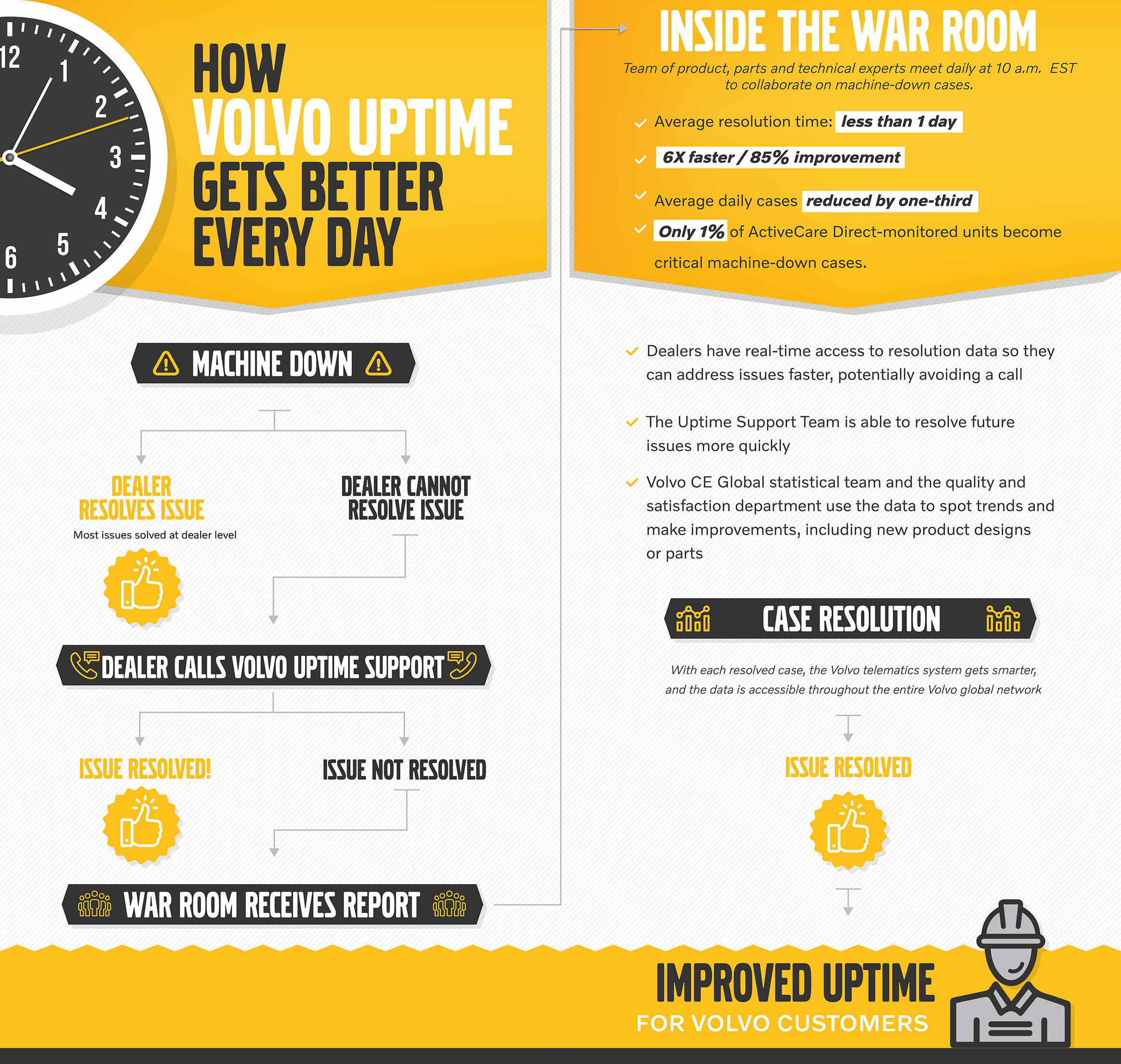

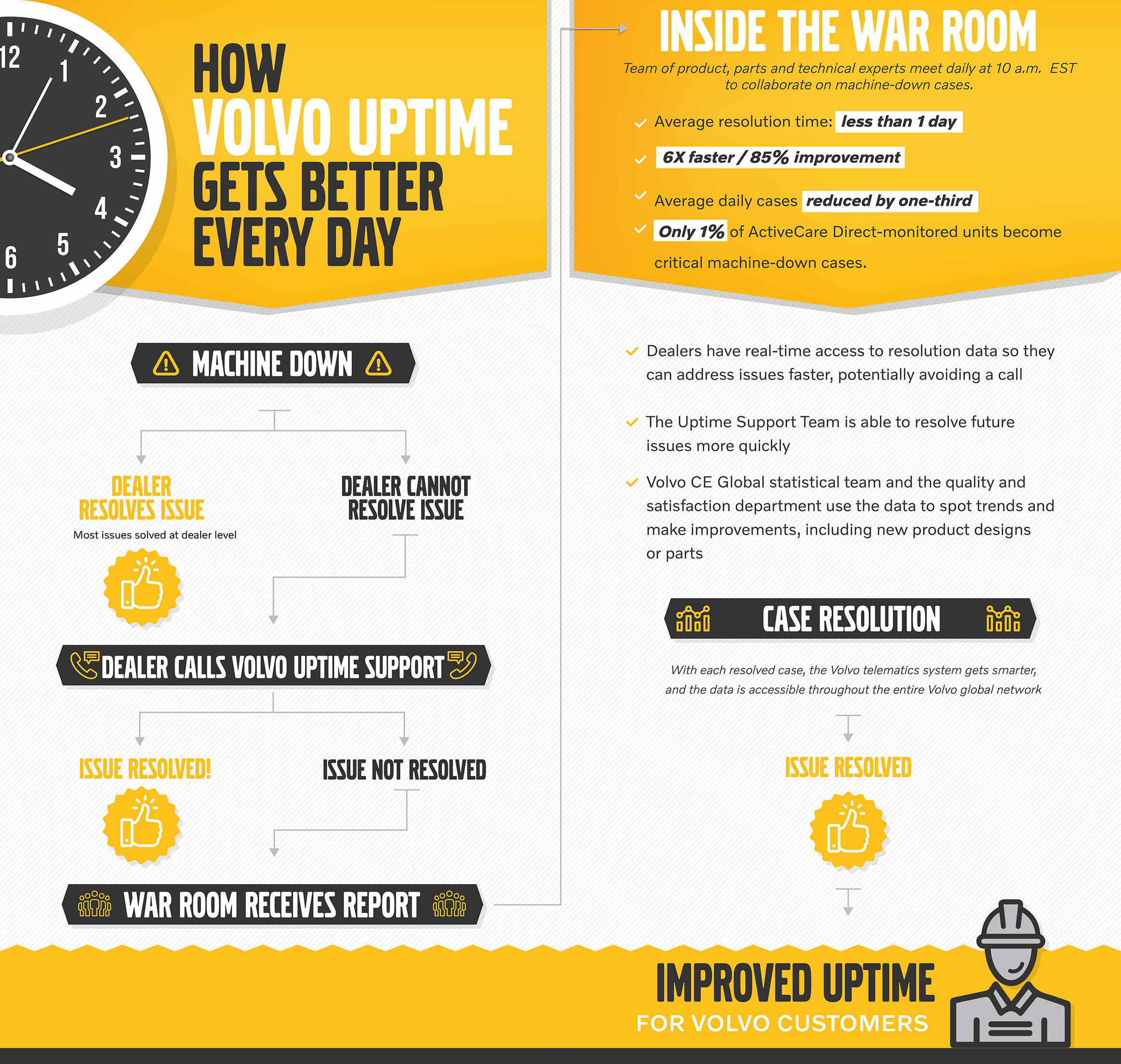

For equipment owners, nothing is more important than machine uptime. The same is true for Volvo CE, and the results of two years of concerted efforts to improve uptime services bear this out:

- Nearly 100% enrollment increase in the ActiveCare Direct® advanced telematics service since fall 2018 — plus a growing list of machine models eligible for the program and additional case alerts for improved machine monitoring.

- Only 1% of ActiveCare Direct monitored units ever become critical machine-down cases.

- 85% improvement in resolution time for critical machine-down cases — thanks to a refined Six Sigma process, most issues are resolved the same day they are reported.

- 97% improvement in the time to reach a Volvo Uptime Support Specialist – due to team cross-training across all product lines.

“We are committed to being the No. 1 uptime provider in the construction industry,” said Scott Young, vice president, uptime and customer support. “That’s why, in addition to producing durable machines, we are providing services that prove to our customers Volvo’s relentless commitment to their uptime.”

Next-level telematics

ActiveCare Direct launched two years ago to “reduce the noise” for equipment owners and fleet managers being inundated with undiagnosed fault codes from traditional telematics systems.

Data from CareTrack, Volvo’s telematics system, is relayed to the Volvo Uptime Center in Pennsylvania. There, analysts and proprietary software sort through thousands of data points and, when an issue needs attention, ActiveCare Direct provides owners and their dealers a case alert with the probable cause, a recommended solution and the consequence of not taking action. Users also receive monthly fleet utilization reports with insights that help them make fleet decisions and address machine misuse issues with operators.

More case alerts are being added all the time, and there are now several hundred unique case alerts, an indication of how the service covers the full machine. Every time a case is closed, ActiveCare Direct learns and continues to improve. An indication of the program’s success is that, of the machines that turn into critical machine down cases, less than 1 percent have ActiveCare Direct.

The number of machines with ActiveCare Direct has nearly doubled since September 2018. Machines purchased prior to the ActiveCare Direct launch can also now upgrade to the program.

“Customers and our dealers are seeing the value in a telematics system that frees them from the burden of data overload while also helping them get in front of potential machine issues before they become a major problem,” Young said.

Additional uptime improvements

When a machine has an issue that cannot be resolved by the local dealer, it elevates to the Volvo Uptime Support team. The team borrows from agile engineering practices to resolve cases faster.

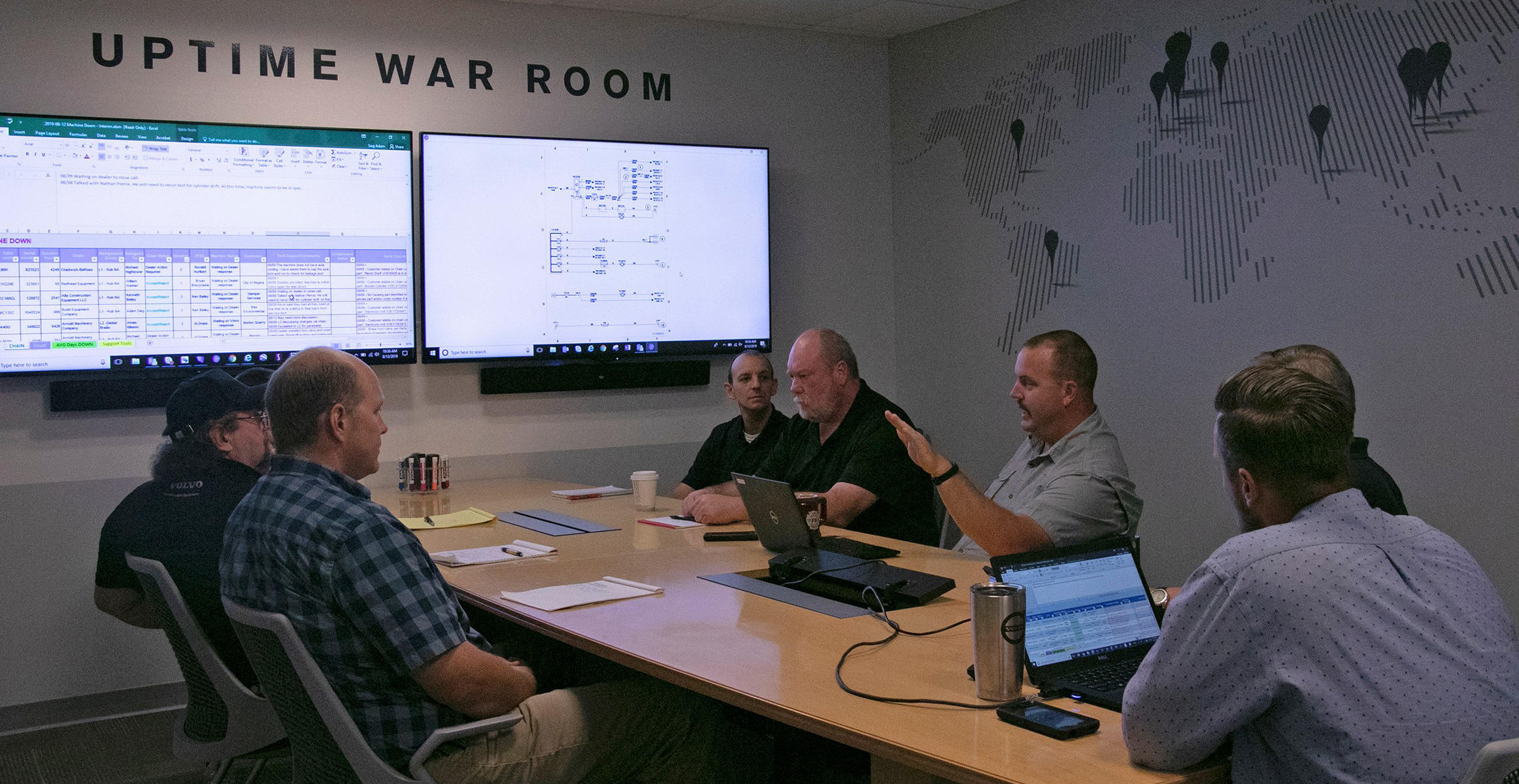

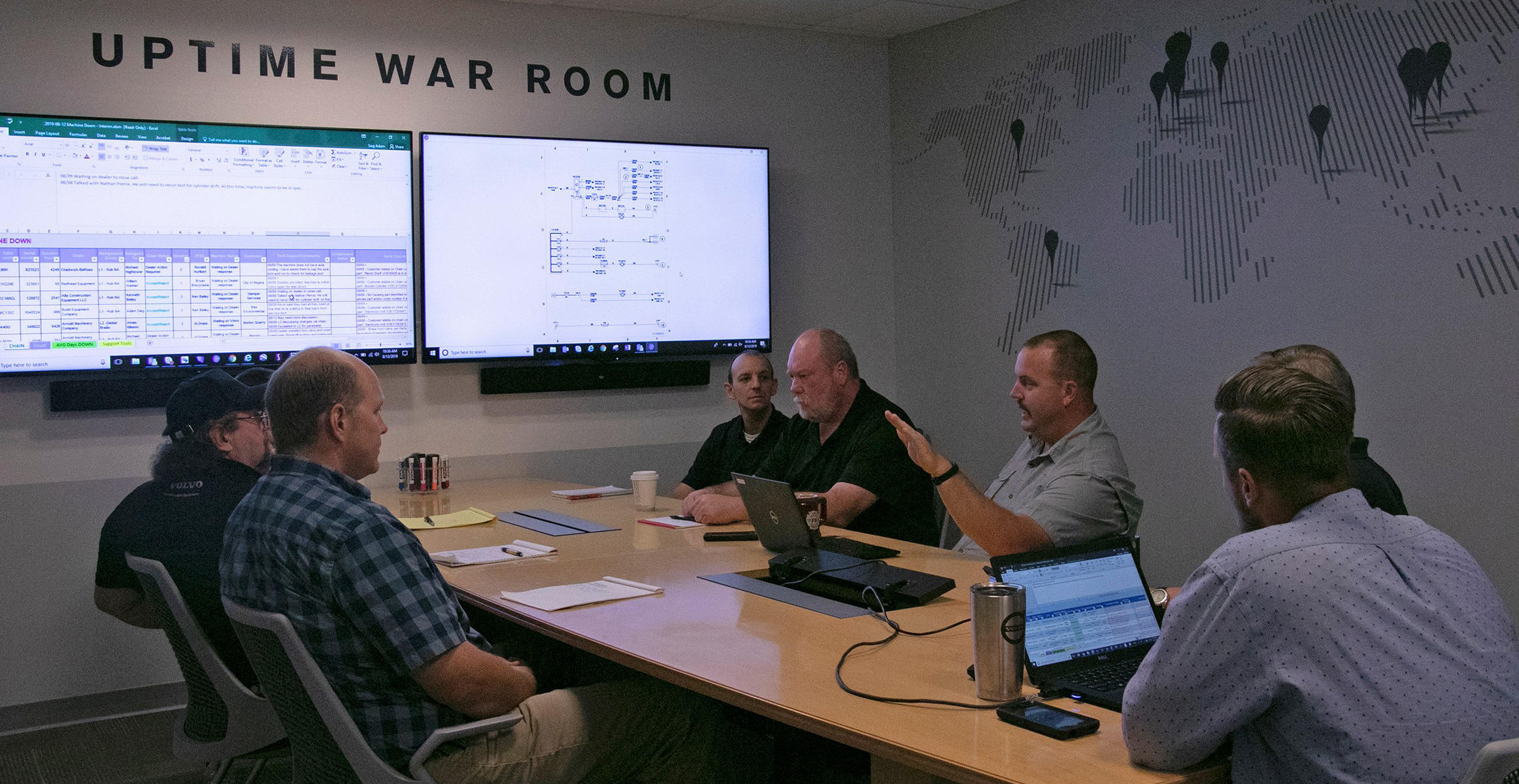

For one hour each morning, the Uptime Support team bunkers down in the “War Room” to analyze and resolve the most critical equipment cases. If needed, field-based technicians and Volvo CE tech support headquartered in Sweden remote in to the War Room via video or phone.

Intense cross-training within the team extended each specialist’s expertise across the entire Volvo product line. This means calls and alerts get immediate attention, shortening the time to reach a product support specialist by 97%.

The Tech Line retooling, combined with ActiveCare Direct and a responsive dealer network to implement these solutions, resulted in an 85% overall improvement in resolution time for critical machine down cases.

“We have an industry-leading process, and we’re doing it with the goal of keeping our customers up and running,” said Rhys Eastham, director of uptime and technical services at Volvo CE.

What’s ahead

The uptime upgrades are far from over. The Tech Line and War Room processes are in a state of continuous improvement thanks to all resolved cases being documented and data being accessible across the entire Volvo global network for faster resolution time from the dealer to the OEM level.

For ActiveCare Direct, Volvo is evaluating ways to show customers information on component life expectancy and finding more machine data points that can be used to improve diagnostic times and parts availability.

Volvo CE also communicates with other Volvo Group subsidiaries, like Volvo Trucks, to identify synergies related to connected technologies, like telematics.

For more information on how Volvo CE handles machine downtime, check out this infographic.