「3D Laser Scanning Virtual Pre-assembly Technology」The three-dimensional laser scanner is used to reconstruct the three-dimensional model of the measured target and other data point cloud models.,Virtual pre-assembly in computer,Easily and efficiently analyze and compare data,Verify the processing, manufacturing and butt joint accuracy of components。In this paper, a hyperboloid pedestrian bridge steel box girder model detection project in Hangzhou undertaken by Zhejiang University is taken as an example.,Explain the Virtual Pre-assembly Application Technology of 3D Laser Scanner in Steel Structure Specialty。

Components need to be pre-assembled, which is common in complex components or structures.、Transport overrun、And poor field installation condition, etc.,This means that pre-assembly is faced with many difficulties.。In order to meet the success rate of one-time assembly and hoisting on site,Ensure the normal operation of the next process and the installation quality meet the specifications.、Design requirements,It takes a lot of manpower and material resources to carry out entity pre-assembly.,And requires a larger space and a longer time.。

Three-dimensional laser scanning virtual pre-assembly technology uses three-dimensional laser scanner to record the three-dimensional coordinates and texture reflectivity of the points on the surface of the measured object.,Quickly reconstruct the surface of the target to be measured、Various data such as volume and three-dimensional model,Then use the software with the functions of point cloud processing and data comparison and analysis(Magnet Collage、Geomagic ControlXEtc),Virtual pre-assembly in computer。In the comparative analysis of model data,The machining dimension deviation data of the component can be simply and efficiently obtained.,More intuitive understanding of the deviation distribution of component butt joints and other key parts,Make point notes for areas with dense deviations or key parts,Verify the processing, manufacturing and butt joint accuracy of components。

Data acquisition by field scanning

Equipment selection

This project has adoptedTopcon GTL-1200 3D laser scanning equipment,Its maximum scanning distance can reach 70m,Scanning speed up to 200000 points/s,The ranging error is ±2mm@50m,It can fully meet the needs of large-scale, fast and high-precision measurement.。

Equipment erection

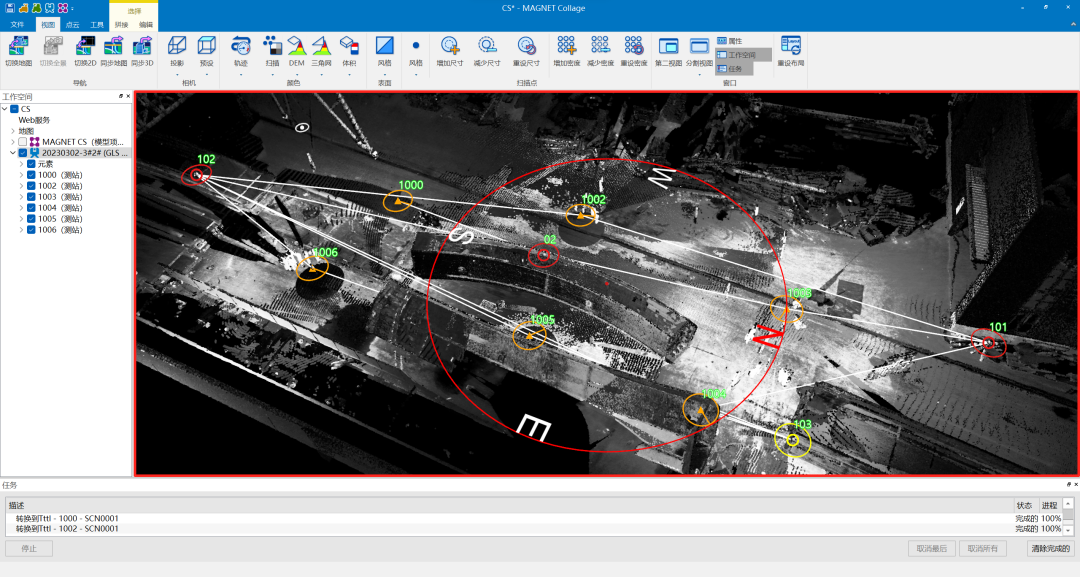

Multi-section members are distributed at different positions on the site according to batch,Portable with 3D scanner、Fast features,Each component translates the site through a different angle,Complete omnidirectional scanning of components on site。

Office data processing

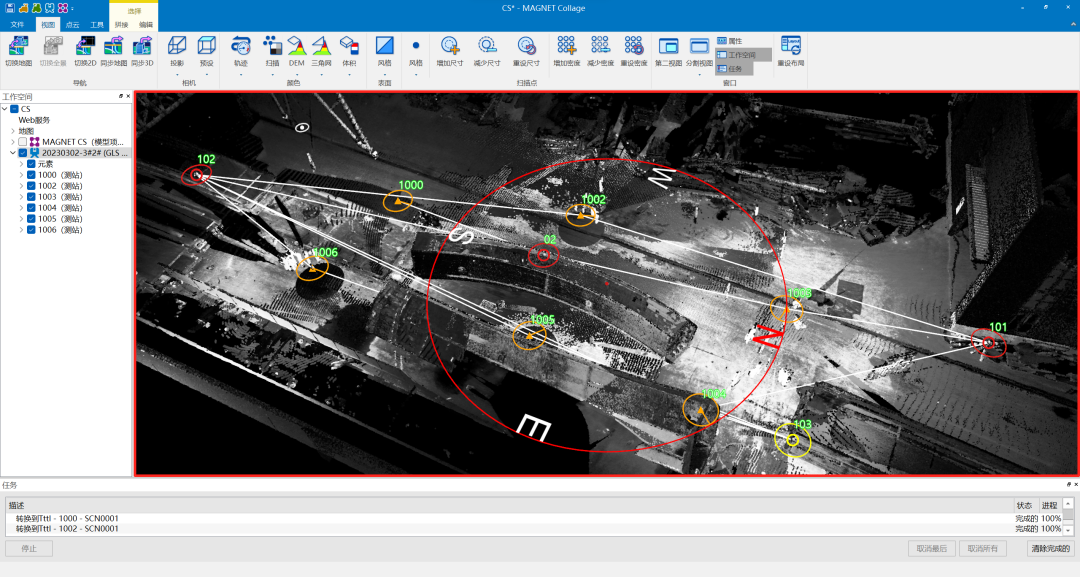

Utilization of data collected from each site in the fieldMagnet CollageSoftware for preliminary processing。

1.Point cloud model processing

Import after scanningMagnet Collage Handle

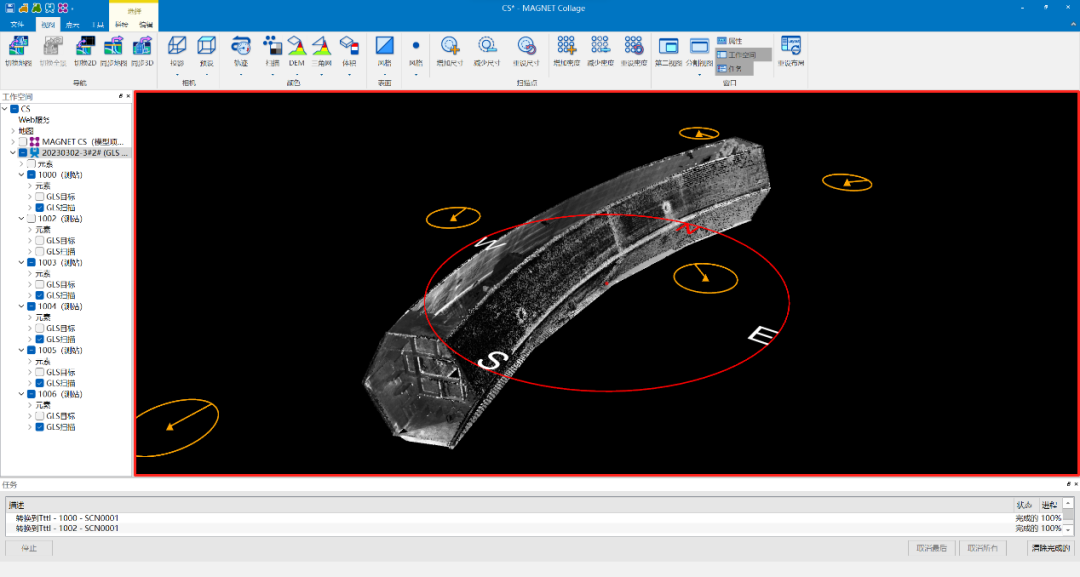

SoftwareMagnet Collage Process the final result

2.Model virtual pre-assembly

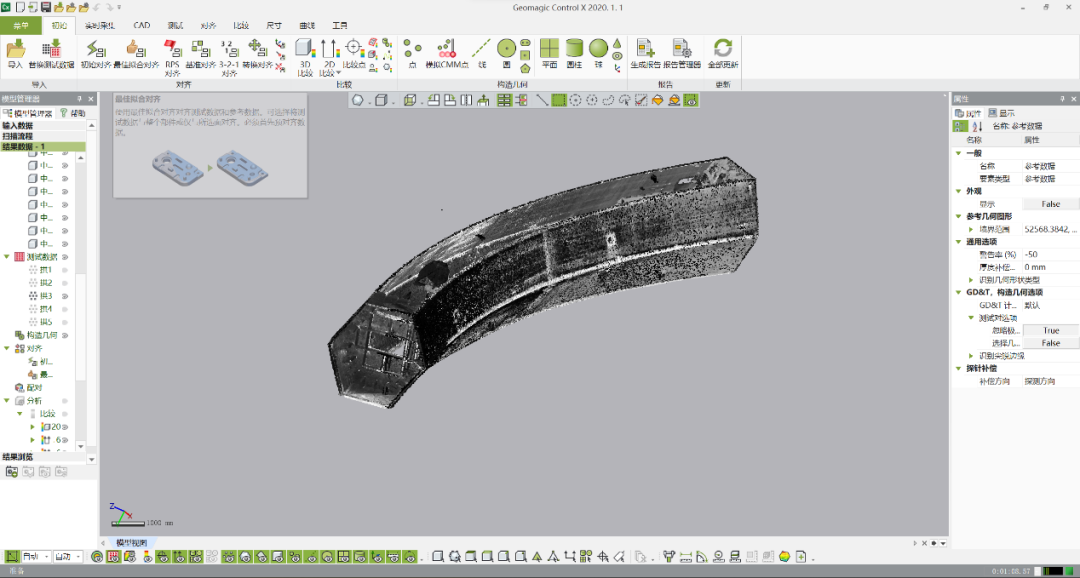

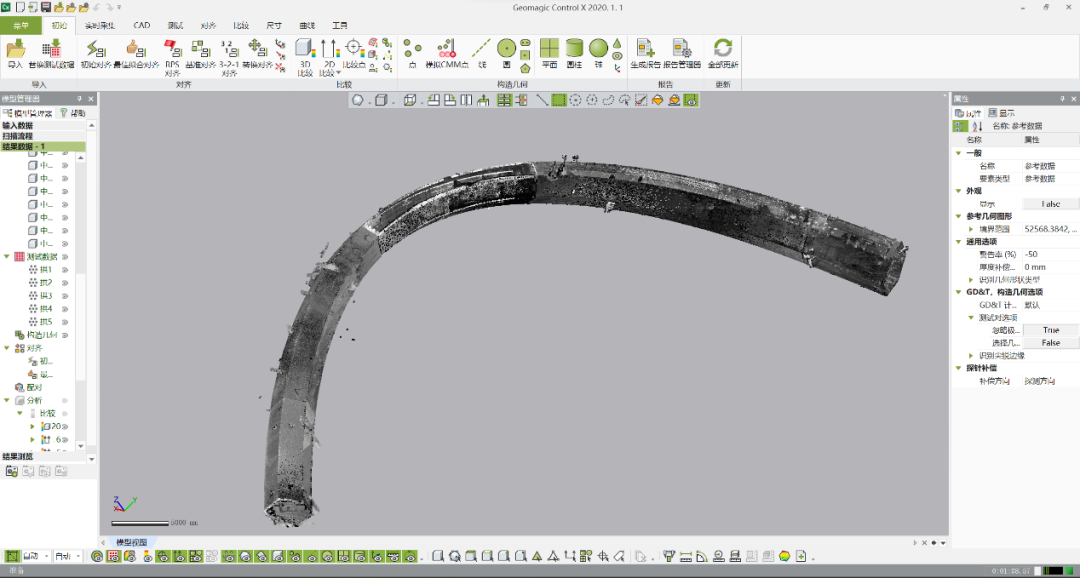

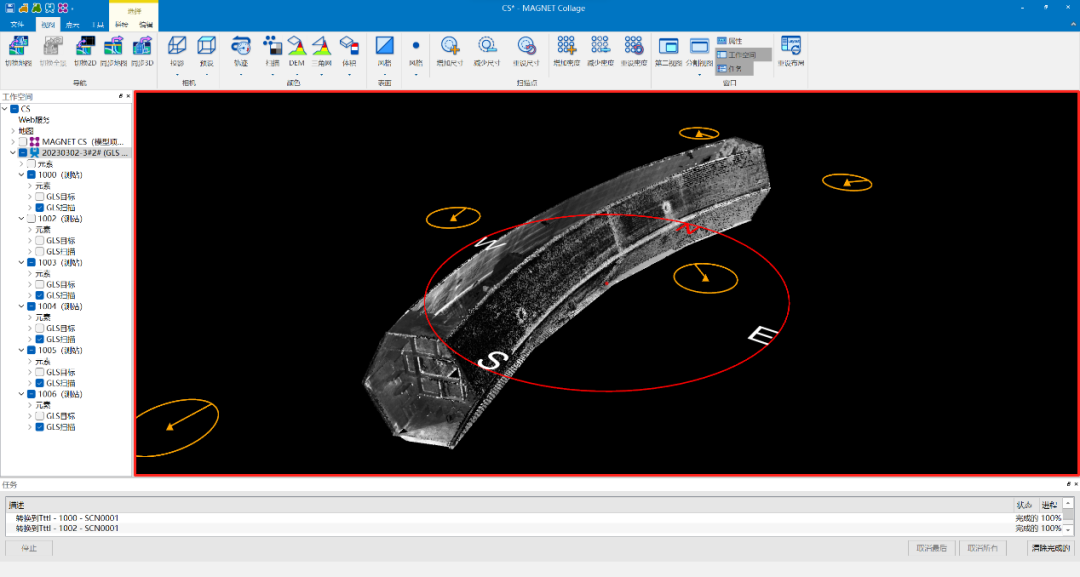

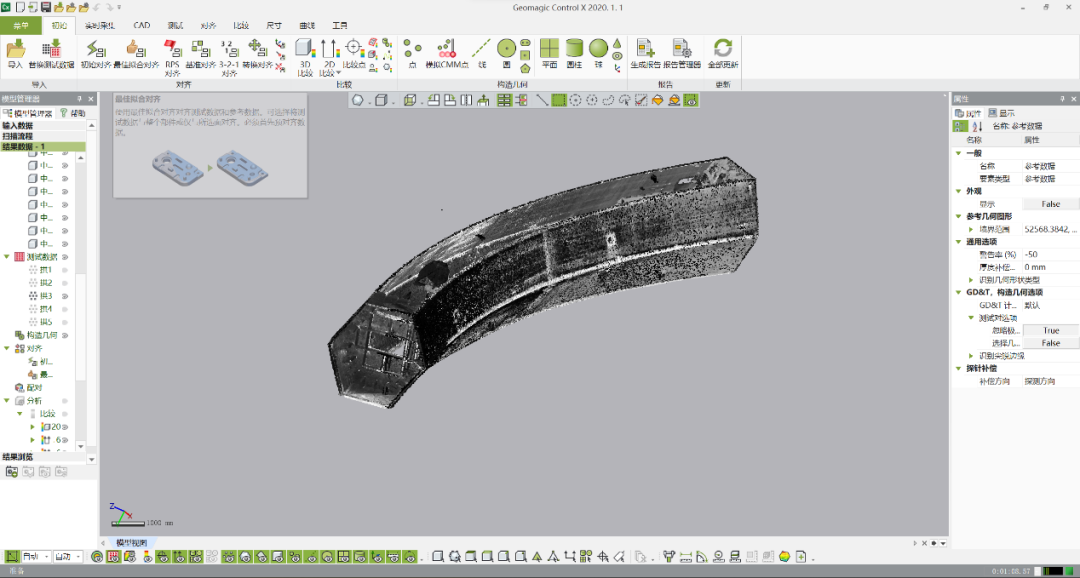

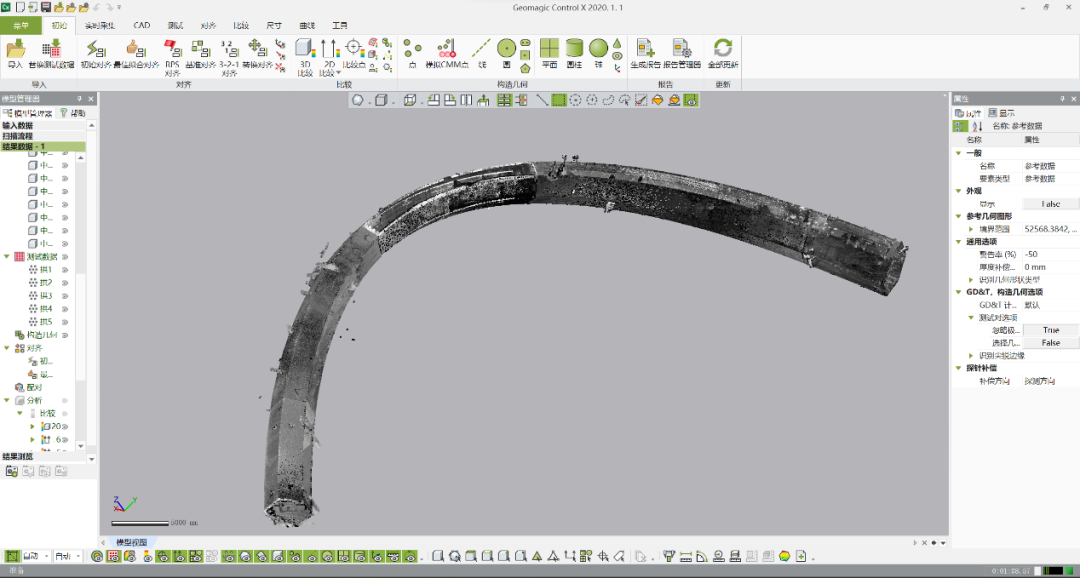

Use the sorted point cloud modelGeomagic ControlXThe software is merged、Splice。

3D Point Cloud Model of Section 3 Middle Arch

Completion of virtual assembly of middle arch of footbridge

3、Comparative analysis

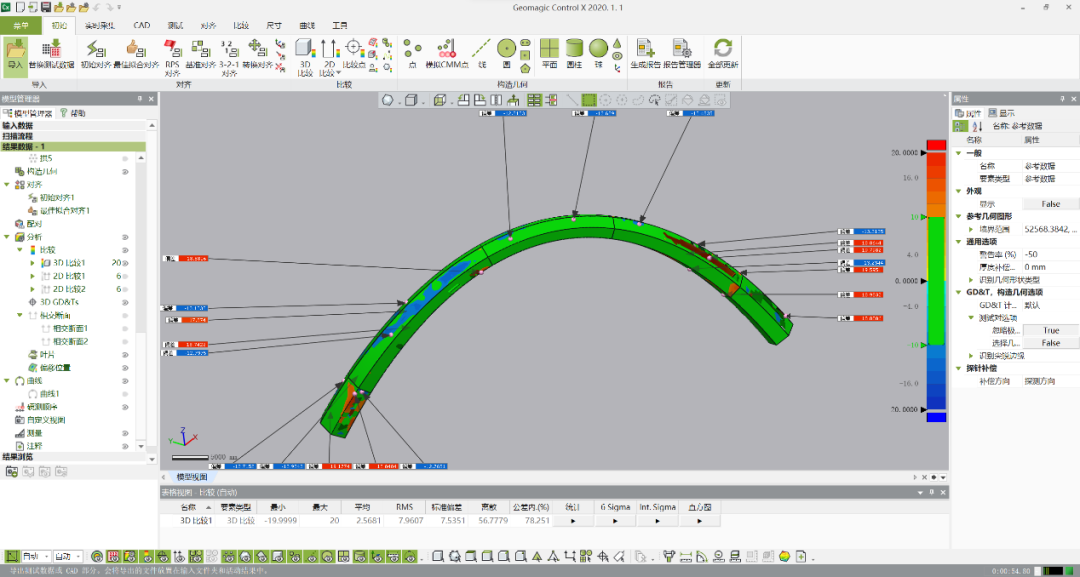

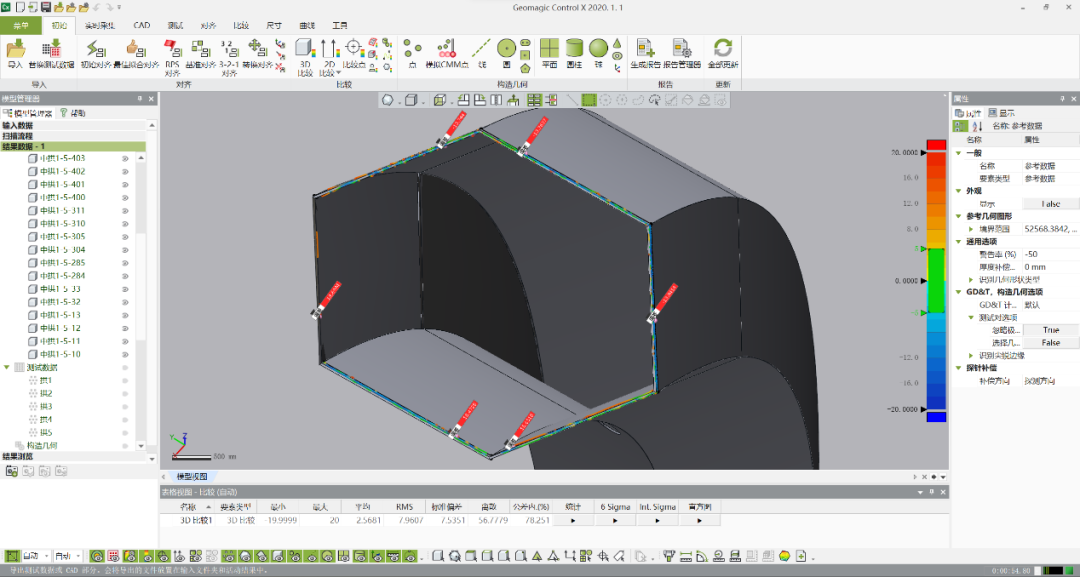

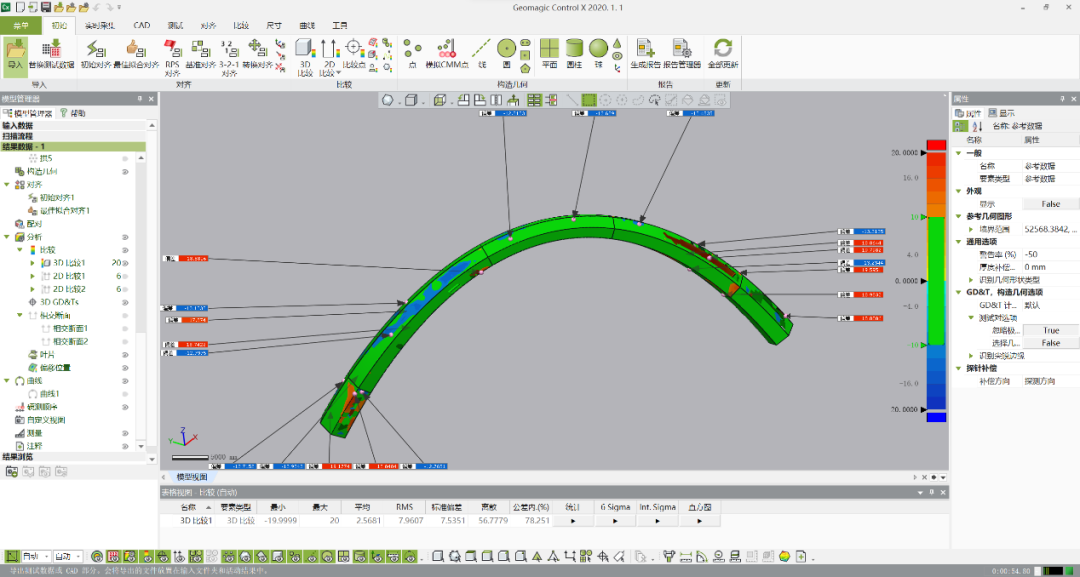

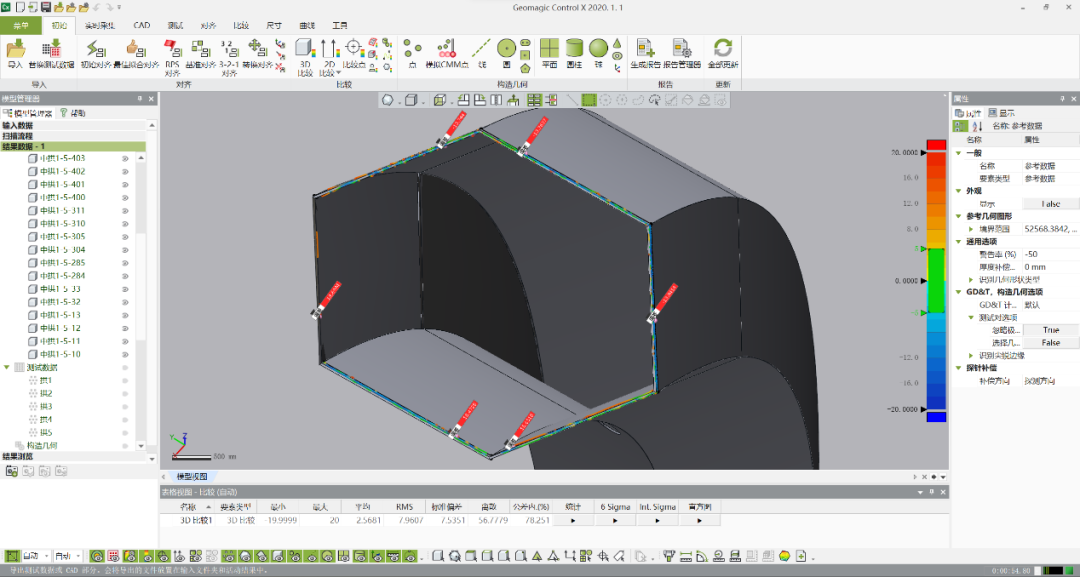

Geomagic ControlXThe software can use the spliced point cloud model and the standard model to carry out 3DOr 2DComparative analysis。3DComparative analysis can give us an intuitive understanding of the overall deviation of the component.,2DComparative analysis can make a more comprehensive comparative analysis of the parts with dense deviations or key parts.。

3DAnnotation analysis

2DAnnotation analysis

By comparing the scanned data with the standard model,,We can intuitively understand the production.、Error of assembly,Unqualified components can be corrected before they leave the factory.,The seriously unqualified products shall be scrapped.,Put an end to unqualified products leaving the factory。At the same time, it can also guide the assembly in the process of assembling the steel arch on site.,Scan the whole after pre-assembly,Welding can be carried out only when the error is within the allowable range.,If the error is too large, it should be adjusted in time according to the comparative analysis results.,Retest after completion of welding,Lifting can be carried out only when the error is within the allowable range.。

Three-dimensional laser scanning virtual pre-assembly technology has fast scanning speed.、And that real-time performance is strong、High precision and the like.。Capable of scanning any object,Directly acquiring high-precision three-dimensional data by adopting a non-contact active measurement mode;。Quickly convert scanned information into data for computer processing,Compared with manual statistical calculation,The possibility of data errors caused by human negligence is avoided.。Deviation data can not only be reflected in the model.,Different colors are used to indicate different deviation range sizes and deviation distributions.,It can also be presented as a chart.。Or create a point annotation,Mark out the detailed dimensional deviation of the member。You can generate a report of all comparative analysis operations with pdfFormat save,Easy to save and view at any time。Review the installation accuracy of steel structure nodes more comprehensively and quickly,Provide basis for subsequent installation,It plays a very positive role in improving the efficiency and quality of steel structure factory processing and on-site installation.。