As of December 1, 2022, non-road mobile machinery”Guo Si“The new standard has officially landed.,China's New Era of Low Carbon and Energy Saving Opens。As originating from northern Europe——This is a well-known brand of road equipment in the most stringent region of global environmental protection laws and regulations.,Dynapac relies on its deep accumulation and foundation in the field of green technology.,In the first time, it launched a new series of paving and compacting products to adapt to the Fourth National Standard.,Continue to lead the trend of high-tech low-emission pavement equipment。

So for the new rules of the fourth national standard.,How has Dynapac upgraded its high-tech products??Following,We will introduce to the vast number of users and friends that Dynapac is now on the stage.SDMany advantages and functions of the fourth national Paver series,These include, but are not limited to, increases in emission levels,It also includes the performance of the whole machine.、Intelligent control system,And security configuration and so on.。

So for the new rules of the fourth national standard.,How has Dynapac upgraded its high-tech products??Following,We will introduce to the vast number of users and friends that Dynapac is now on the stage.SDMany advantages and functions of the fourth national Paver series,These include, but are not limited to, increases in emission levels,It also includes the performance of the whole machine.、Intelligent control system,And security configuration and so on.。

Power upgrade

Full rangeSDPaver,Carry the imported CumminsB6.7 Engine,Powerful、Low carbon and environmental protection;

Post-processing is integratedDOC(Diesel oxidation catalyst)+DPF(Diesel particulate filter)+SCR(Selective catalytic reduction)+ASC(Ammonia leakage catalyst)Post-processing,Convenient installation;

EngineECUThe module has been upgraded iteratively.,Faster processing、More stable machine operation;

EquippedVGTVariable area turbocharger,Greatly improve low-speed response speed;

Prospective Continuity Design,The engine and aftertreatment basically do not need to be changed,Only adaptive upgrading can meet the emission requirements of the next five stages.;

A urea tank is added,Diesel urea consumption ratio of 10:1;

4-in-1 cooling system,Diesel cooler added。

Intelligent upgrade

Intelligent stepless speed change function,Make the engine change speed automatically according to the working condition,O as to achieve the purposes of energy conservation, emission reduction and noise reduction.;

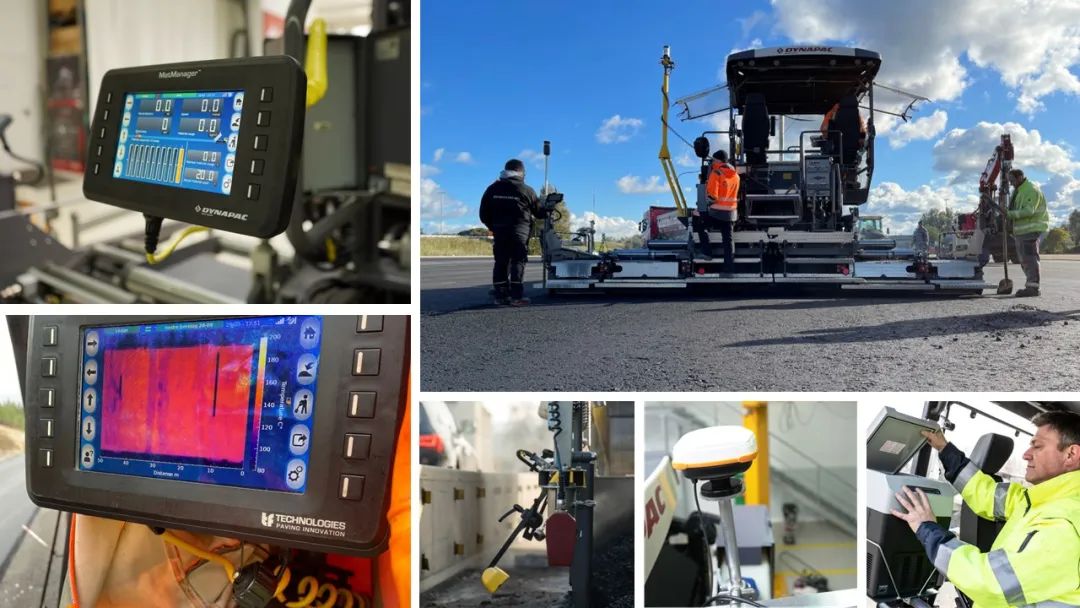

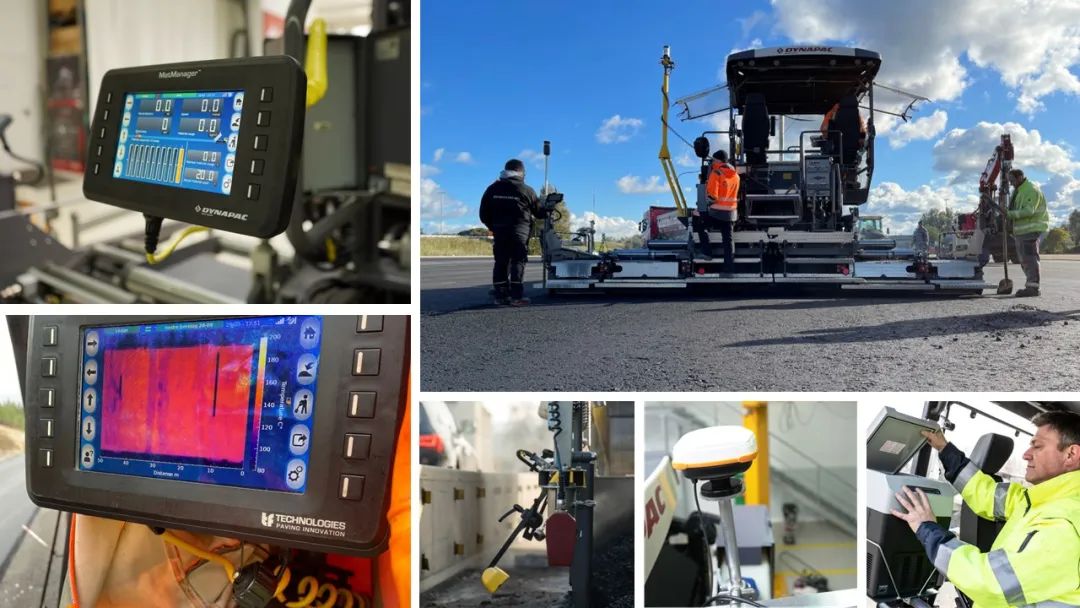

The whole series is equipped with paving management 2.0 Advanced Control System;

Standard configurationDyn@LinkPremium version,Real-time monitoring of fuel level、Fuel consumption、Engine status、Working hours, etc.,And can be customized to generate reports and monitor service status,Geofencing to limit work area。Professional version can realize remote active monitoring function.,Active sending of fault information、Causes and required spare parts;

Side Control 2.0 Control system,Screed with two-speed control,The leveling parameters of both sides can be displayed on one edge control.;

Convenience upgrade

One-key start-stop function of engine;

New electric lifting roof;

Hydraulic auger lift as standard;

Standard centralized lubrication;

Cleaning system with pipe winder as standard,Daily maintenance equipment is more convenient and faster;

Standard configuration“Accompany me home function”Auxiliary lighting system,It is a more humane and intimate design.;

Hydraulic arch adjusting function,Can be operated not only from the main control panel,It can also be controlled by the side box。

Stability upgrade

SatisfyCEClosed-loop Control Systems for Safety Requirements,And is more stable and reliable;

Upgraded screed structural design,Greater resistance to deformation;

New Generation Track Drive System,Lead to better traction and operational stability;

Reinforced fixed front flap、Chain guard、Push the roller、Scraper drive sprocket,Greatly enhance equipment durability;

More intelligent high-tech options

Multiple trimming options available+Collapsible edge trim system+Trimming lamp;

Intelligent paving managementMatManager2.0 system+MatScannerThermal imaging system+High precisionGNSSAntenna。Equipped with a full-color display、Weather station temperature sensor、For data transmissionGSMModule,On-site or remote monitoring of paving data including material consumption,Thermal imaging data can be uploaded toMatWiserAnalyze in the cloud,It can also be passedUSBThe interface transmits data,GNSSThe antenna greatly improve that positioning accuracy of the system;

Automatic tracking of cutting edgeMatTrackerSystem,Curbs can be traced,The screed automatically extends and retracts,Save manpower,Reduce the risk of operation;

High Tech 3DLeveling system,Achieve high precision3DSpreading;

Refrigerator/Incubator——Caring for the intimate configuration of the mobile phone。

DynapacSDSeries Paver,Take the switching of the four new regulations as an opportunity,Comprehensively improve the performance and configuration of the equipment,Continue to Practice Dynapac with High Technology as the Driving Force in the Fourth National Era、Customer demand-oriented operation concept。Join hands with you,Build the future together!

So for the new rules of the fourth national standard.,How has Dynapac upgraded its high-tech products??Following,We will introduce to the vast number of users and friends that Dynapac is now on the stage.SDMany advantages and functions of the fourth national

So for the new rules of the fourth national standard.,How has Dynapac upgraded its high-tech products??Following,We will introduce to the vast number of users and friends that Dynapac is now on the stage.SDMany advantages and functions of the fourth national